Burned pepper chilli sauce and making method thereof

A technology of chili sauce and chili, which is applied in the food field, can solve problems that have not yet appeared, and achieve the effect of excellent shelf life and spicy and full taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

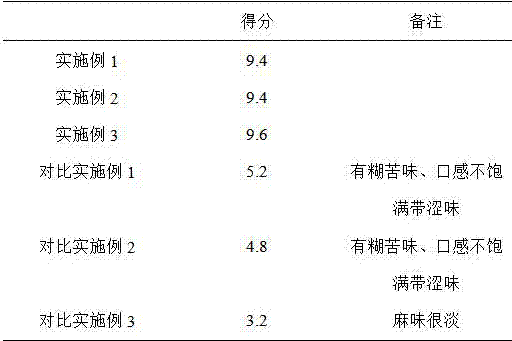

Examples

Embodiment 1

[0027] (1) Prepare the following component raw materials in parts by weight:

[0028] 200 parts of fresh chili peppers, 22 parts of minced garlic, 8 parts of green peppercorns, 6 parts of minced lotus, 3 parts of amomum, 80 parts of tempeh, 6 parts of comfrey, 40 parts of white wine;

[0029] (2) Roast the fresh stalked peppers in step (1) until the surface is softened and black skin appears, and the area of black skin accounts for 60% of the skin area of the pepper; then put it in cold water quickly;

[0030] (3) Heat the cooking oil to high temperature, add the green pepper in step (1), stir-fry for 10-15 seconds, remove and discard the oil;

[0031] (4) Heat another 160 parts of cooking oil, put the amomum and comfrey in step (1), cook for 2~3 minutes, and keep the solid and cooking oil respectively;

[0032] (5) Cut the result of step (2) into sections or cubes, add the minced garlic, fermented soy sauce and white wine in step (1), the result of step (3) and the solid...

Embodiment 2

[0035] (1) Prepare the following component raw materials in parts by weight:

[0036] 180 parts of fresh capsicum, 20 parts of minced garlic, 5 parts of green peppercorns, 3 parts of minced lotus, 2 parts of amomum, 60 parts of tempeh, 5 parts of comfrey, 30 parts of white wine;

[0037] (2) Roast the fresh stalked peppers in step (1) until the surface softens and black skin appears, and the area of black skin accounts for 40% of the skin area of peppers; then put it in cold water quickly;

[0038] (3) Heat the cooking oil to high temperature, add the green pepper in step (1), stir-fry for 10-15 seconds, remove and discard the oil;

[0039] (4) Heat another 150 parts of edible oil, put the amomum and comfrey in step (1), boil for 2~3 minutes, and keep the solid and edible oil respectively;

[0040] (5) Cut the result of step (2) into sections or cubes, add the minced garlic, fermented soy sauce and white wine in step (1), the result of step (3) and the solid obtained in s...

Embodiment 3

[0043] (1) Prepare the following component raw materials in parts by weight:

[0044] 185 parts of fresh capsicum, 21 parts of minced garlic, 7 parts of green peppercorns, 5 parts of minced lotus, 2.5 parts of amomum, 66 parts of tempeh, 5.5 parts of comfrey, 35 parts of white wine;

[0045] (2) Roast the fresh stalked peppers in step (1) until the surface softens and black skin appears, and the area of black skin accounts for 50% of the skin area of the pepper; then put it in cold water quickly;

[0046] (3) Heat the cooking oil to high temperature, add the green pepper in step (1), stir-fry for 10-15 seconds, remove and discard the oil;

[0047] (4) Heat another 155 parts of cooking oil, put the amomum and comfrey in step (1), boil for 2~3 minutes, and keep the solid and cooking oil respectively;

[0048] (5) Cut the result of step (2) into sections or cubes, add the minced garlic, fermented soy sauce and white wine in step (1), the result of step (3) and the solid obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com