PCB milling cutter with replaceable cutter head

A technology of cutter heads and milling cutters, which is applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems affecting the overall rigidity of milling cutters, high scrap rate, and general performance, so as to save the part of the cutter bar, improve stability, The effect of a stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

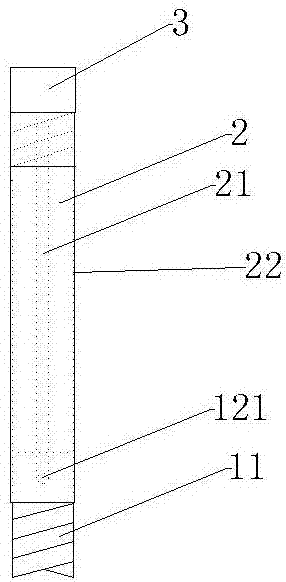

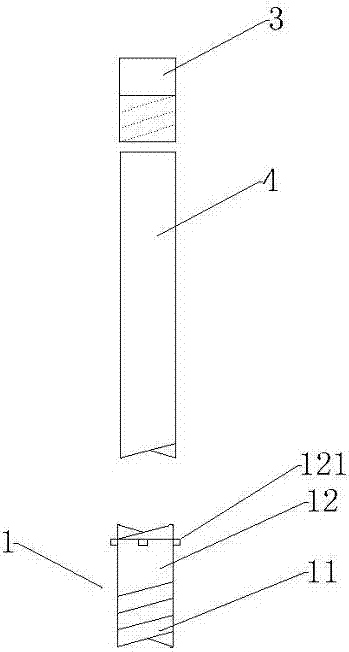

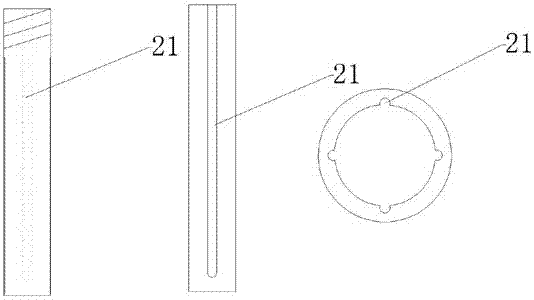

[0017] Such as figure 1 , figure 2 , image 3 As shown, a PCB milling cutter with a replaceable cutter head includes a cutter head 1, a sleeve 2, a fixed end 3 for closing the top opening of the sleeve 2, and a fixing rod for fixing the cutter head 1 4. Both ends of the casing 2 are open, one end is connected to the cutter head 1, and the other end is connected to the fixed end 3, and an external thread is provided on the top of the casing 2, and the fixed end 3 is provided with There are internal threads, the sleeve 2 and the fixed end 3 are threadedly connected, and the inner wall of the sleeve 2 is evenly distributed along the length direction of the sleeve 2. Four long grooves 21 can also be used to set One turn of the gear turning card slot can make the space between the cutter head 1 and the sleeve 2 more firm and prevent slippage. The end of the long slot 21 close to the fixed end 3 opens to the top of the sleeve 2. One end close to the cutter head 1 is closed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com