Mortar stirring operating table with cleaning device

A cleaning device and mortar mixing technology, which is applied in the direction of measuring devices, cement mixing devices, clay preparation devices, etc., can solve the problems of rust spots on the pot body, reduce the weight of materials, and not easy to clean, so as to prevent splashing, improve efficiency and success rate, avoid the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions will be clearly and completely described below in conjunction with the drawings and embodiments of the present invention. Describe the scheme of the present invention in detail below in conjunction with specific embodiment:

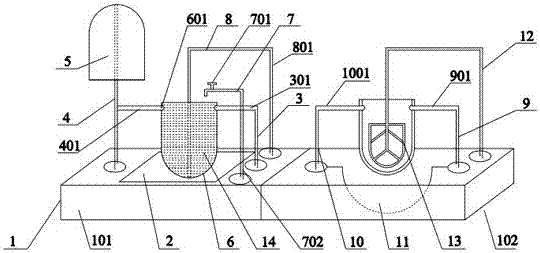

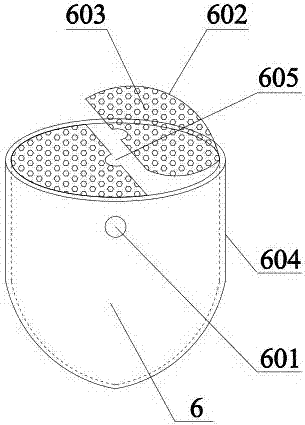

[0024] As an embodiment of the present invention, as shown in the figure, a mortar mixing operation platform with a cleaning device includes a support platform 1, and a stirring pot 6, a stirring blade 13, and a cleaning device arranged on the support platform 1. The support platform 1 is divided into a cleaning platform 101 and a mixing platform 102. On the cleaning platform 101, a water tank 2 is provided in the center, and a vertical support rod I4 is provided on one side of the water tank 2. In the water tank 2 The other side is provided with a vertical support rod II3 and a cleaning device; on the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com