Construction method for temporary plugging wall for utility tunnel

A technology of integrated pipe gallery and construction method, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of rubber waterstop damage, affecting the waterproof performance of deformation joints, etc., to ensure normal operation and remove the sealing wall convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

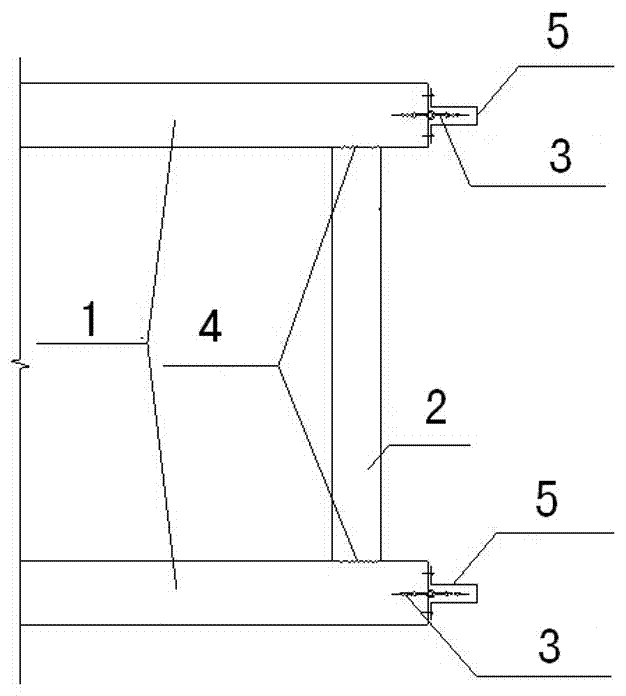

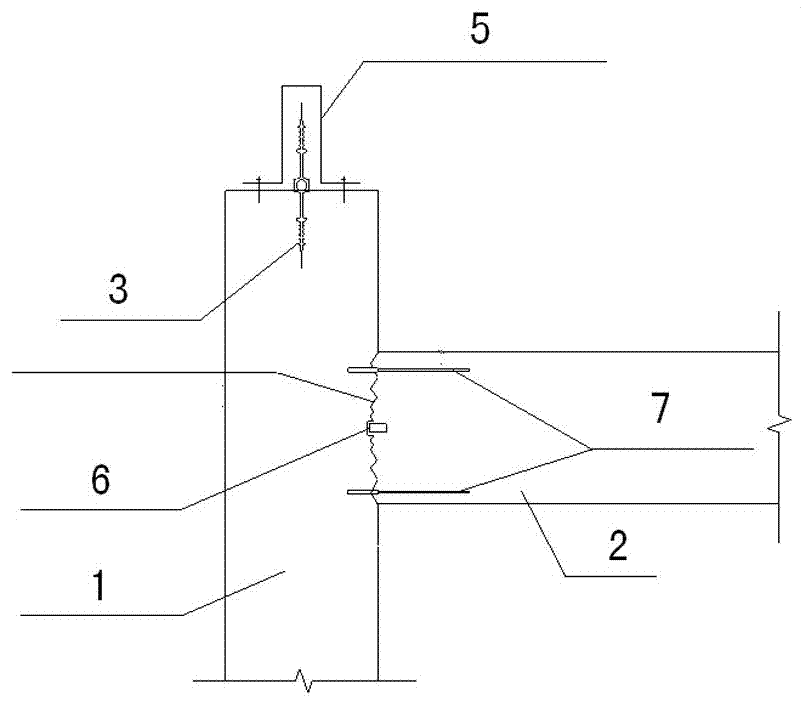

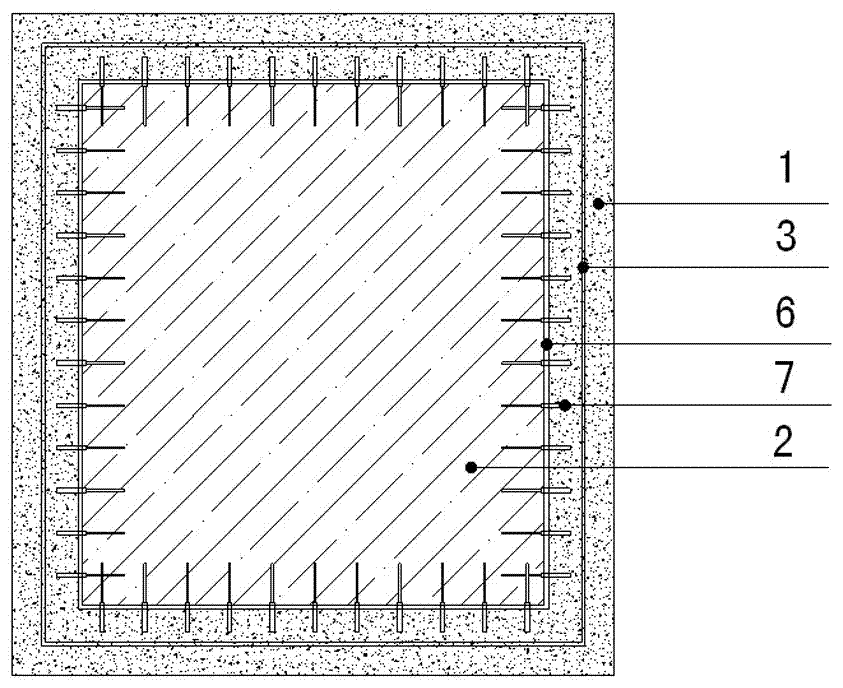

[0020] The figure includes comprehensive pipe gallery wall board 1, sealing wall 2, rubber waterstop 3, connection interface 4 between comprehensive pipe gallery wall board and sealing wall, stainless steel plate 5, water-swellable rubber strip 6, and planting reinforcement 7.

[0021] The temporary sealing wall structure of the comprehensive utility gallery is provided with a sealing wall 2, a rubber waterstop 3 and a stainless steel plate 5 for protection. The rubber waterstop 3 is pre-buried in the center of the wall panel at the end of the pipe gallery and forms a circle; the sealing wall 2 is set at a position 300mm away from the end of the pipe gallery, such as figure 1 shown.

[0022] The detailed measures of the construction of the temporary sealing wall are as follows: figure 2 shown. The exposed side of the waterstop is protected by wrapping a protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com