High pressure jet grouting power head

A technology of high-pressure rotary spraying and power head, which is applied in the direction of drilling with liquid/gas jet, drilling equipment, sheet pile wall, etc. It can solve the problems of increased drill pipe length, high center of gravity of drill pipe, and inconvenient installation, so as to prevent leakage , Lower the height of the center of gravity and shorten the longitudinal length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

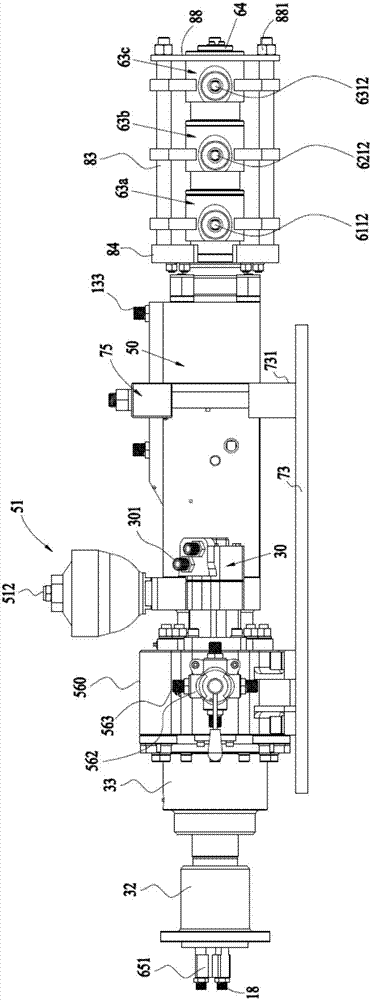

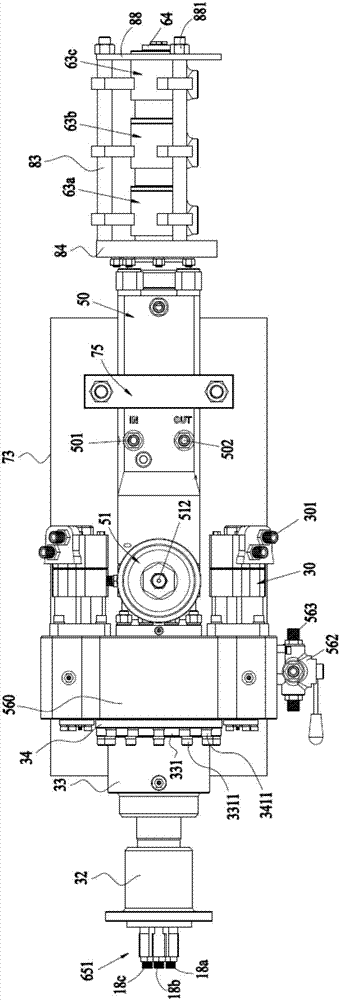

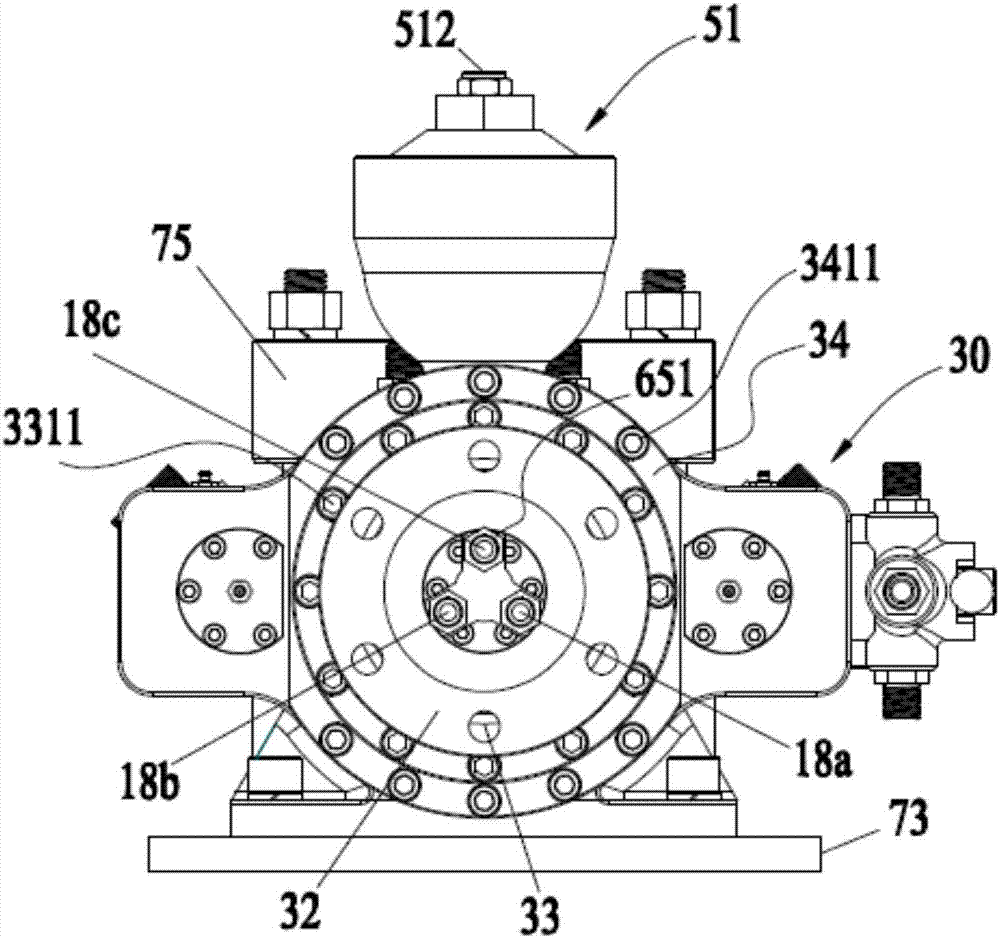

[0103] ginseng Figure 1 to Figure 15 Shown is a specific implementation of the high-pressure rotary jet power head of the present invention.

[0104] A high-pressure rotary spraying power head shown in this specific embodiment is mainly used for reinforcement of various soft and hard foundations, anti-seepage treatment of basements of high-rise buildings, regulation of large river dams, and reinforcement of railway and road bridge piers.

[0105] Specifically, in this embodiment, the high-pressure rotary spraying power head incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com