Oil well gas injection method

A technology for oil wells and gas injection, which is applied in earthwork drilling, wellbore/well components, production fluids, etc. It can solve the problems of inability to achieve accurate calculation of formation pressure, prediction error of pure gas injection pressure at the wellhead, and inability to meet the requirements of pure nitrogen injection in Tahe River. Wellhead pressure requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

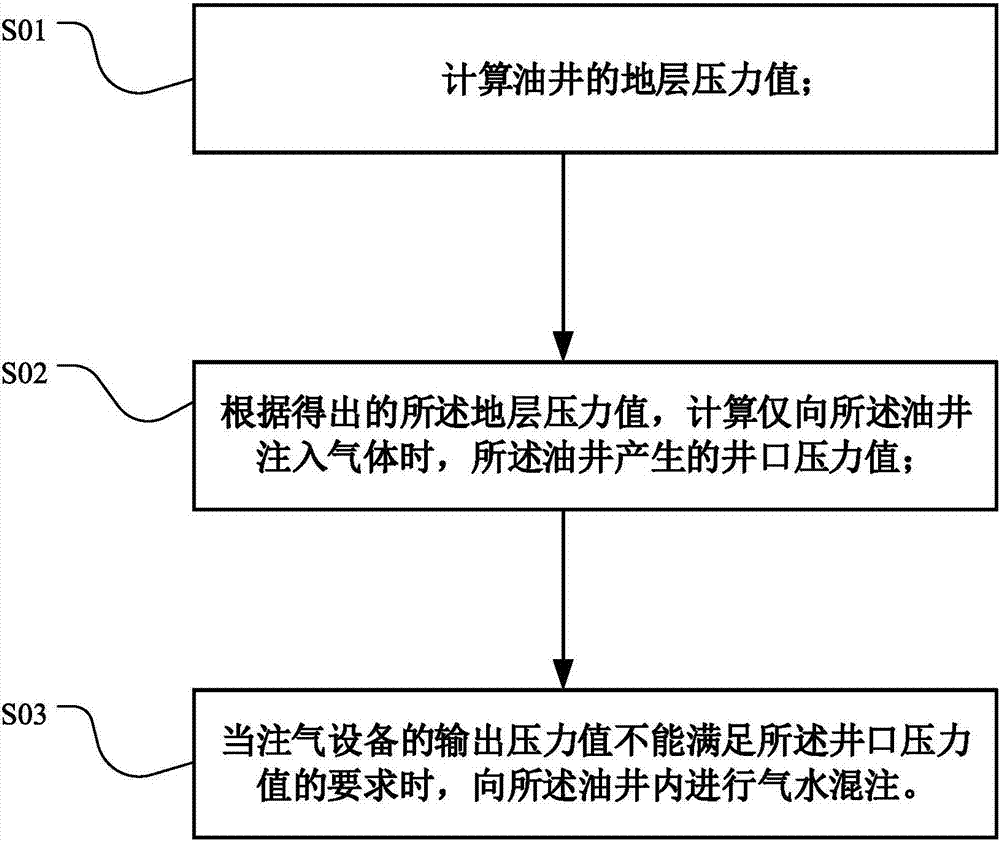

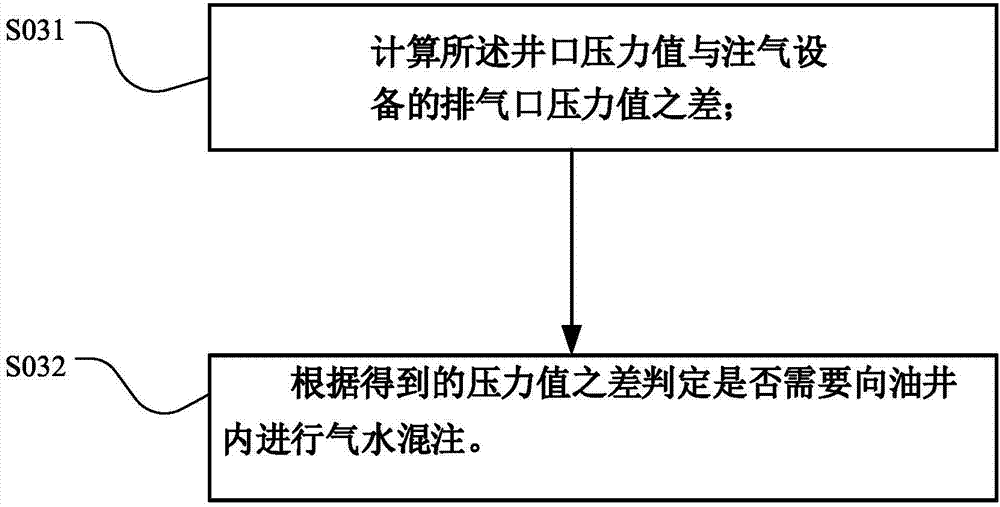

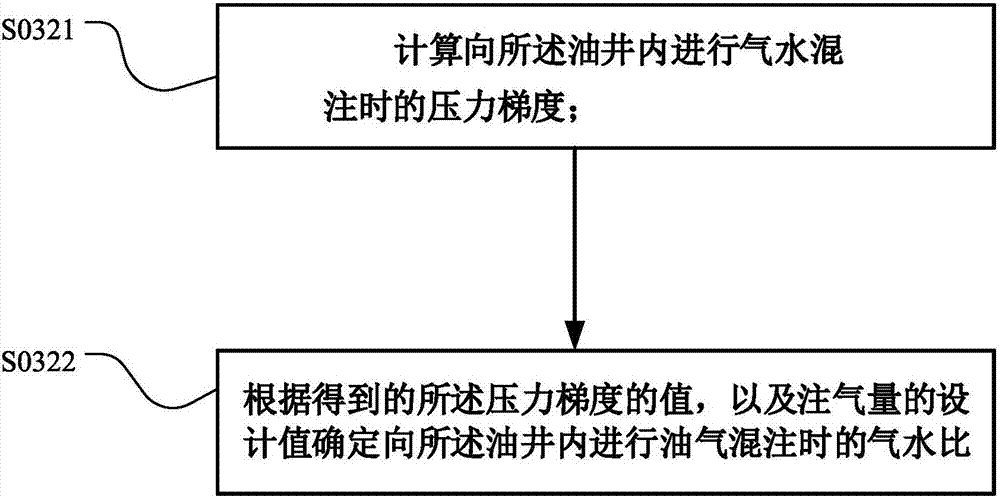

[0043] like figure 1 As shown, the present invention provides a gas injection method for oil wells. The gas injection method for oil wells determines the working conditions and chooses to use existing gas injection equipment to inject gas into the oil well or perform gas-water mixed injection into the oil well. The gas injection method is suitable for ultra-deep oil wells, especially for the calculation of gas injection pressure and gas-water mixed injection ratio of oil wells where the formation pressure is high and the existing gas injection equipment cannot realize pure gas injection. In this embodiment, the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com