Single-linkage, damping and impact-resisting non-centering type constant-angular-velocity cardan joint

An anti-shock and universal joint technology, applied in the field of universal joints, can solve the problems of high machining accuracy, restricted use range, vibration and noise, etc., and achieve the effects of low friction, low production cost and reduced lubricating oil film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention will be further described below in conjunction with the accompanying drawings.

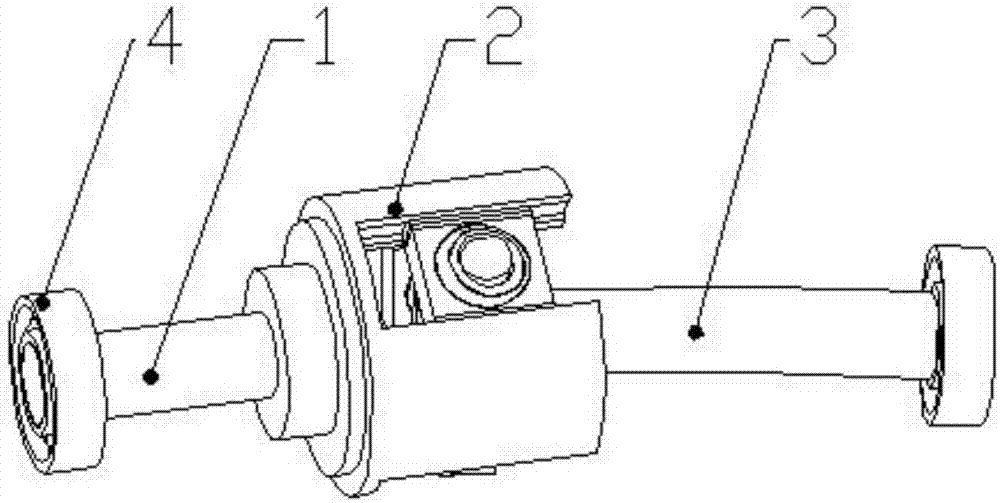

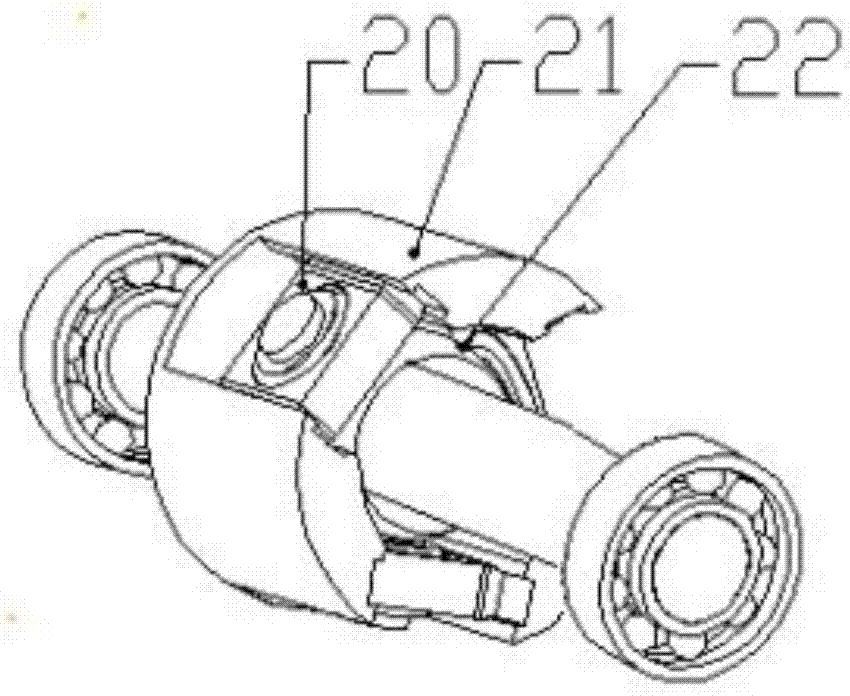

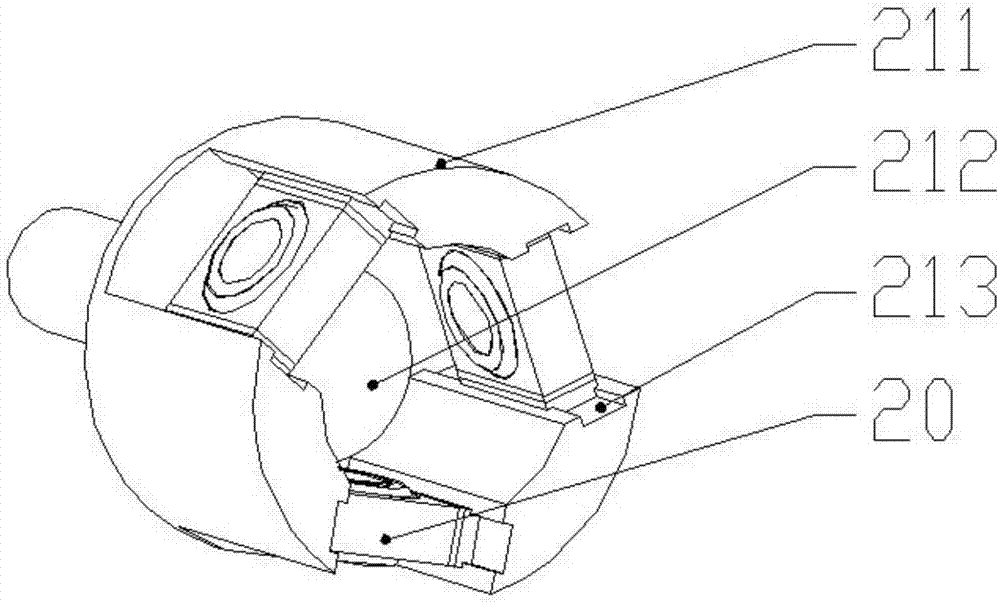

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the non-centering type constant angular velocity universal joint with single vibration reduction and shock resistance of the present invention includes: input shaft 1, universal joint 2, output shaft 3, fixed bearing 4; the fixed bearing 4 has two sets, which are respectively connected to one end of the input shaft 1 and the output shaft 3, the other end of the input shaft 1 is connected to the universal joint 2, and the universal joint The tripod 22 of the joint 2 is splined to one end of the output shaft 3; the universal joint 2 includes: a slider assembly 20, a universal joint body 21 and a tripod 22; the slider assembly 20 has three sets , the sleeve 211 of the universal joint body 21 is a cylindrical structure, and three sets of slide grooves 213 are opened on the wall of the sleeve 211, which are distributed at 120°; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com