Regenerative heat exchanger with improved sealing frame

A heat exchanger, regenerative technology, applied in heat exchanger sealing devices, heat exchange equipment, regenerative heat exchangers, etc., can solve problems such as unprovided solutions, achieve calculation work and readjustment reduction, reduction The effect of work and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

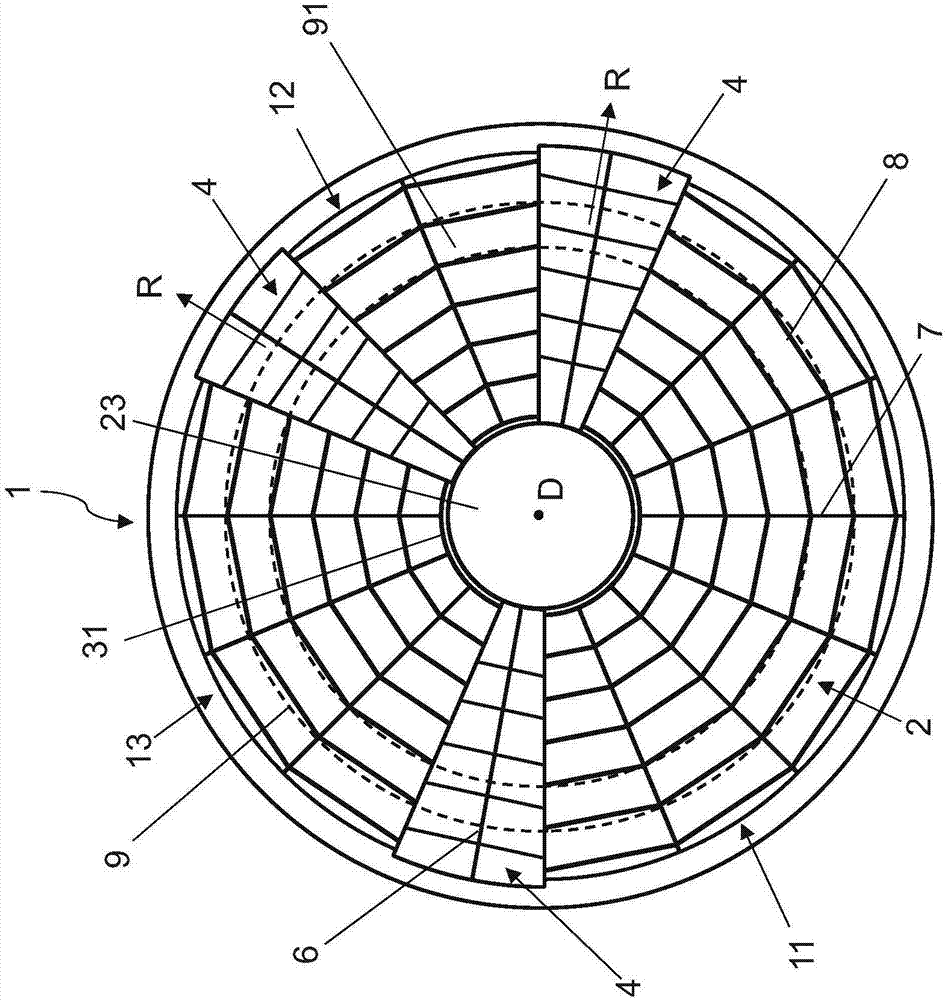

[0030] image 3 A top view along the axial direction D of the heat exchanger 1 according to the invention is shown. The heat accumulator configured as a rotor 2 is surrounded by a stationary housing 3 , is mounted rotatably about an axis of rotation D and is constructed essentially as is known from the prior art. The thermal storage elements 8 are arranged in concentric rings 9 around the rotor core 23 . These rings 9 are subdivided by radial walls 7 extending outwards from the rotor core. The multiple gas volume flows of different temperature flows through the heat exchanger 1 are substantially parallel to the axis of rotation D, but in opposite directions. These gas volume flows can be, for example, a hot flue gas flow and one or more cold combustion air flows. Accordingly, in the example shown, the heat exchanger 1 comprises one flue gas sector 11 and two air sectors 12 , 13 . A direct exchange of gas between the individual cells 91 and thus also between the flue gas sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com