Device and method for measuring steam and non-condensable gas flow

A gas flow and steam technology, applied in the direction of measuring device, volume flow measuring device, liquid/fluid solid measurement, etc., can solve the problem that steam and non-condensable gas cannot be detected at the same time, and achieve ingenious structure, accurate measurement and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

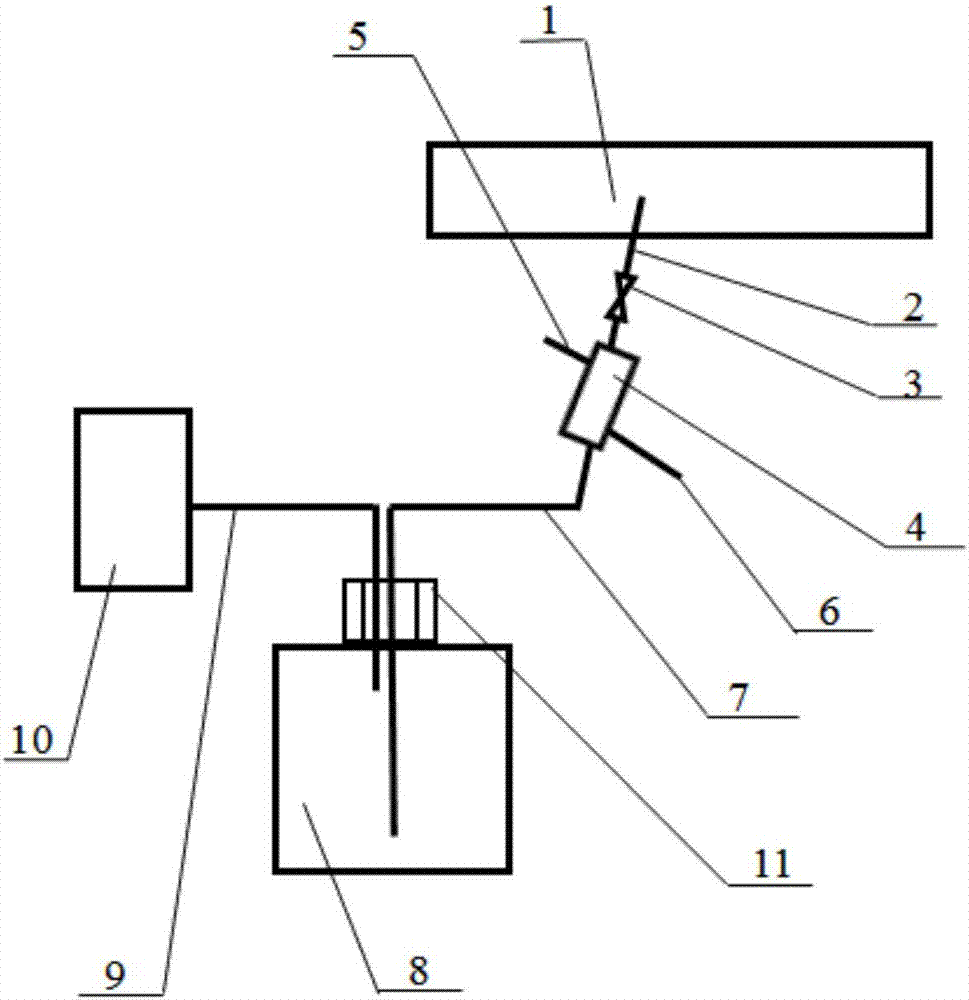

[0025] see figure 1 , a device for measuring the flow of steam and non-condensable gas, the device includes an air induction pipe 7, a cooler, a condensate bottle 8 and a flow meter, wherein one end of the cooler is connected to the air induction pipe 7, and the other end introduces a mixed gas ; The other end of the bleed air pipe 7 is connected to the gas condensate bottle 8;

[0026] Steam and non-condensable gas can flow through the air induction pipe 7 and the cooler, condense after being cooled by the cooler and flow into the condensate bottle 8 for weighing. The non-condensable gas flows through the flow meter to measure the flow rate after passing through the bleed air pipe 7, the condensate gas cylinder 8 and the connecting pipe 9. The device has an ingenious structure, is simple and compact, requires less power, is energy-saving, environment-friendly and low in cost.

[0027] Wherein, in a feasible implementation, the cooler is a cold water jacket 4 , and the cold ...

Embodiment 2

[0036] A device for measuring the flow of steam and non-condensable gas. An exhaust pipe 2 is installed on the main air pipe 1, and an exhaust valve 3 is installed on the pipe. Exhaust pipe 2 is connected with bleed air pipe 7. A cold water jacket 4 is installed on the air-inducing pipe 7, and a water outlet 5 and a water inlet 6 are respectively installed on the cold water jacket 4. The air induction pipe 7 is inserted into the condensate bottle 8, one end of the connecting pipe 9 is connected with the float flowmeter 10, the other end of the connecting pipe 9 is inserted into the condensate bottle 8, the condensate bottle 8, the air induction pipe 7 and the connecting pipe 9 Seal with sealing plug 11.

[0037] The device for measuring steam and non-condensable gas flow of the present invention, when in use:

[0038] When working, the mixed air flow of steam and non-condensable gas flows through the main air pipe 1, and the exhaust valve 3 on the exhaust pipe 2 is opened. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com