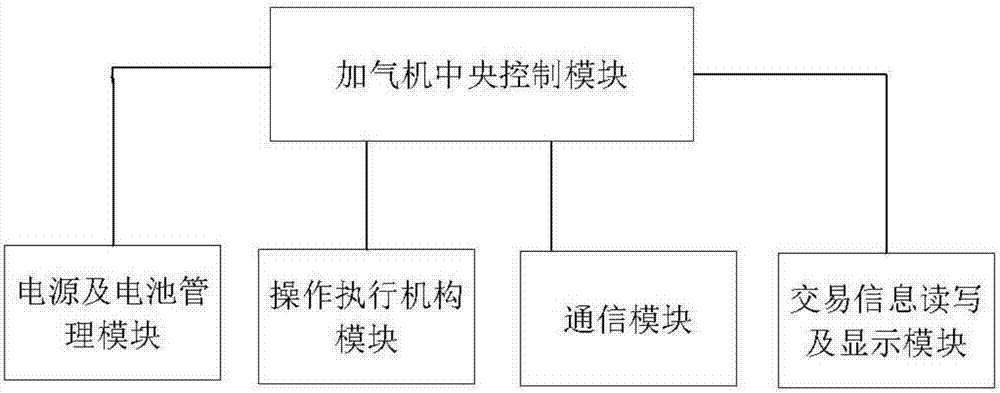

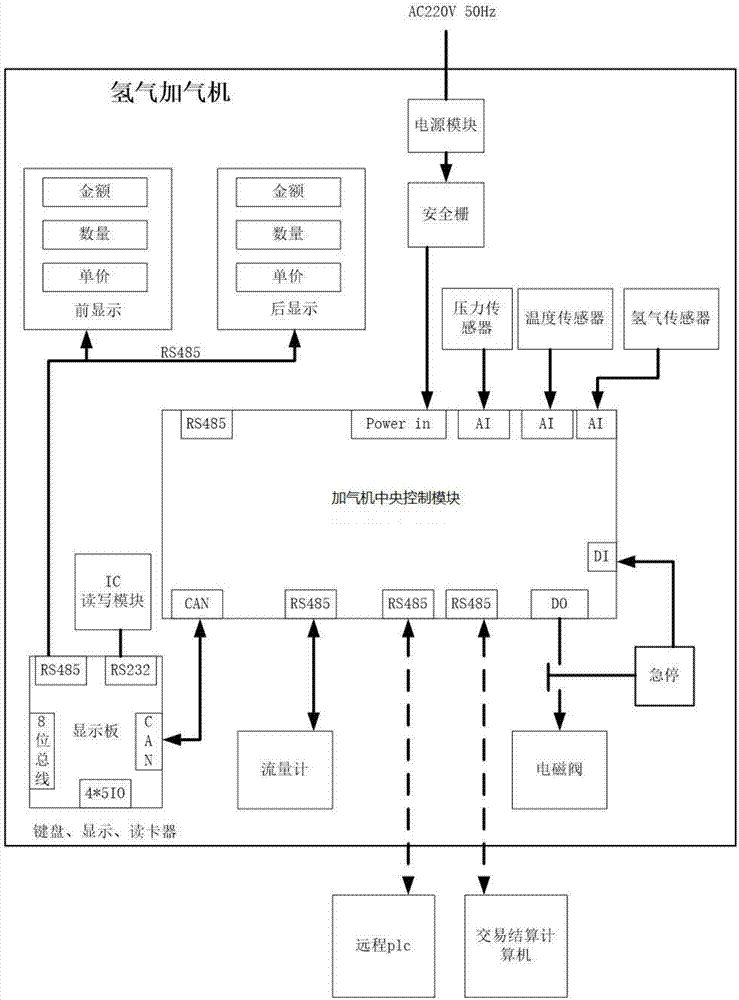

Electric control system of hydrogen gas adding machine and gas adding method thereof

A gas dispenser, hydrogen technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problems of non-automation, low efficiency, labor-intensive, etc., and achieve the effect of clear hardware structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

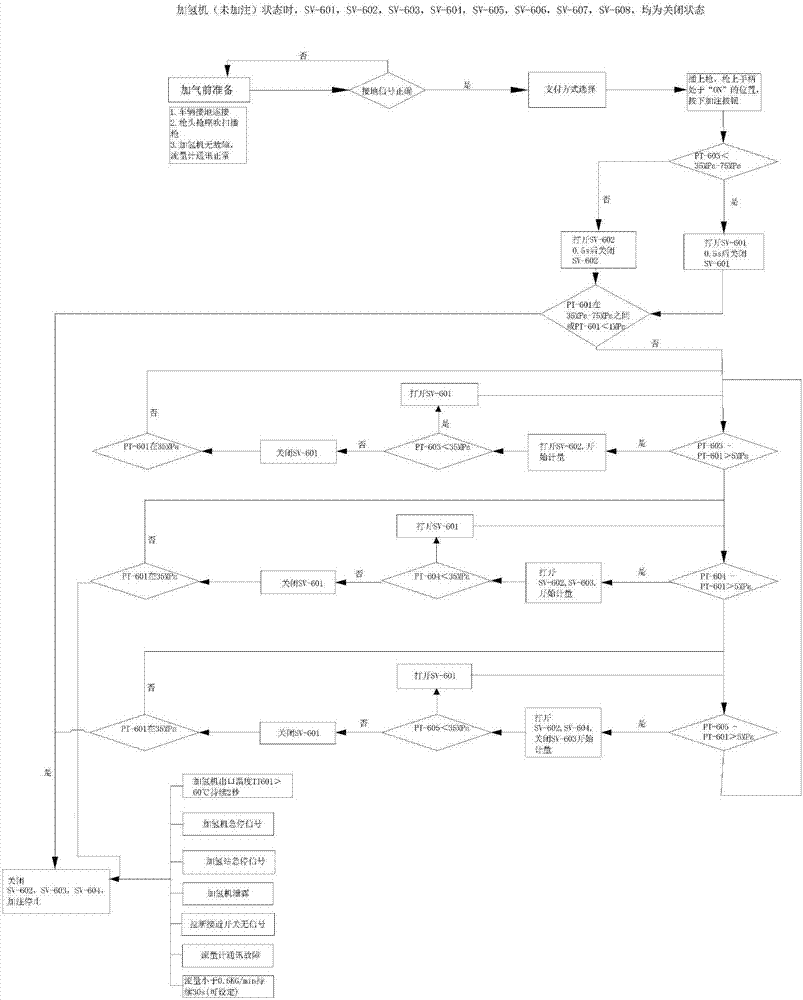

[0039] use figure 1 The system and method, the pressure pipeline is a group, fill 200 yuan of hydrogen, press the filling button, start filling, judge whether the pressure of the low-pressure pipeline PT-603 is less than 35Mpa-75Mpa, if it is less than open the bypass valve SV-6010.5 seconds , to collect and judge whether the pressure of the gas storage tank PT-601 is less than 1Mpa or greater than or equal to 35Mpa (less than 1Mpa indicates that there is a leak, and equal to 35Mpa indicates that the gas storage tank is full), and if so, stop hydrogenation.

Embodiment 2

[0041] use figure 1 The system and method, the pressure pipelines are two groups, add 200 yuan of hydrogen, press the filling button to start filling, when there are two pressure pipelines, judge whether the pressure of the low-pressure pipeline PT-603 is less than 35Mpa-75Mpa, if it is less than Then open the bypass valve SV-60 for 10.5 seconds, collect and judge whether the pressure of the gas storage tank PT-601 is less than 1Mpa or within the range of 35Mpa-75Mpa (less than 1Mpa means there is leakage, and the range of 35Mpa-75Mpa indicates that the gas storage tank is full ), if it is, stop the hydrogenation, otherwise start to judge whether the pressure difference between the low-pressure pipeline and the gas storage tank PT-603 minus PT-601 is greater than 5Mpa, if it is, open the SV-602, start metering, and check whether the pressure of the low-pressure pipeline PT-603 is If it is not less than 35Mpa, close the bypass valve SV-601, judge whether the pressure of the gas...

Embodiment 3

[0043] use figure 1 The system and method, the pressure pipeline is divided into three groups, fill 200 yuan of hydrogen, press the filling button to start filling, the hydrogenation process is: judge whether the pressure of the low pressure pipeline PT-603 is less than 35Mpa-75Mpa, if it is less than, open the side Open the valve SV-60 for 10.5 seconds, collect and judge whether the pressure of the gas storage tank PT-601 is less than 1Mpa or within the range of 35Mpa-75Mpa (less than 1Mpa indicates that there is leakage, and the range of 35Mpa-75Mpa indicates that the gas storage tank is full), if If yes, stop hydrogenation, otherwise start to judge whether the pressure difference between the low-pressure pipeline and the gas storage tank PT-603 minus PT-601 is greater than 5Mpa, if yes, turn on SV-602, start metering, and check whether the pressure of the low-pressure pipeline PT-603 is less than 35Mpa, If it is not less than 35Mpa, close the bypass valve SV-601, judge whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com