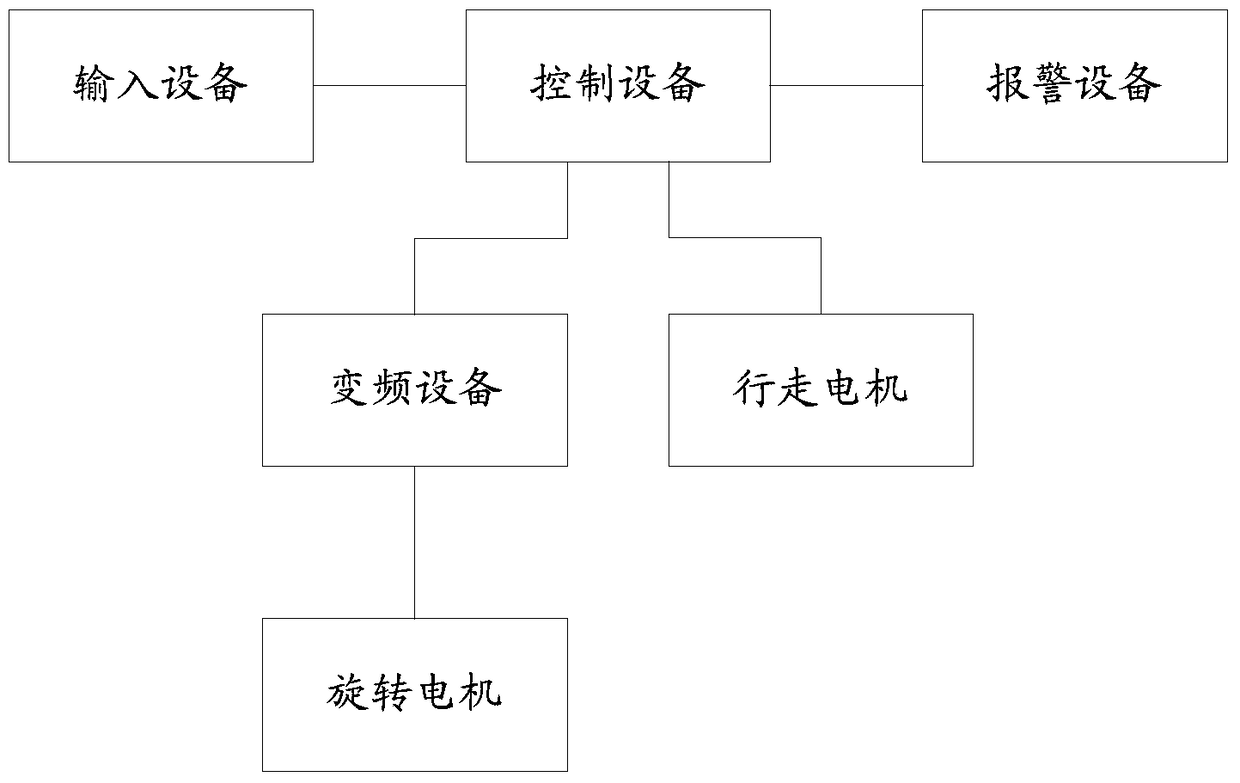

A spraying control system

A technology for spraying paint and controlling equipment, which is applied in the direction of electrical program control, sequence/logic controller program control, etc. It can solve the problems that only manual spraying of paint can only be done manually, so as to protect health, improve applicability, and ensure spraying effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] The steps of spraying by the embodiment of the present invention are as follows:

[0048] First of all, it needs to be explained that, before the spraying control system provided by the embodiment of the present invention works, all valves are closed.

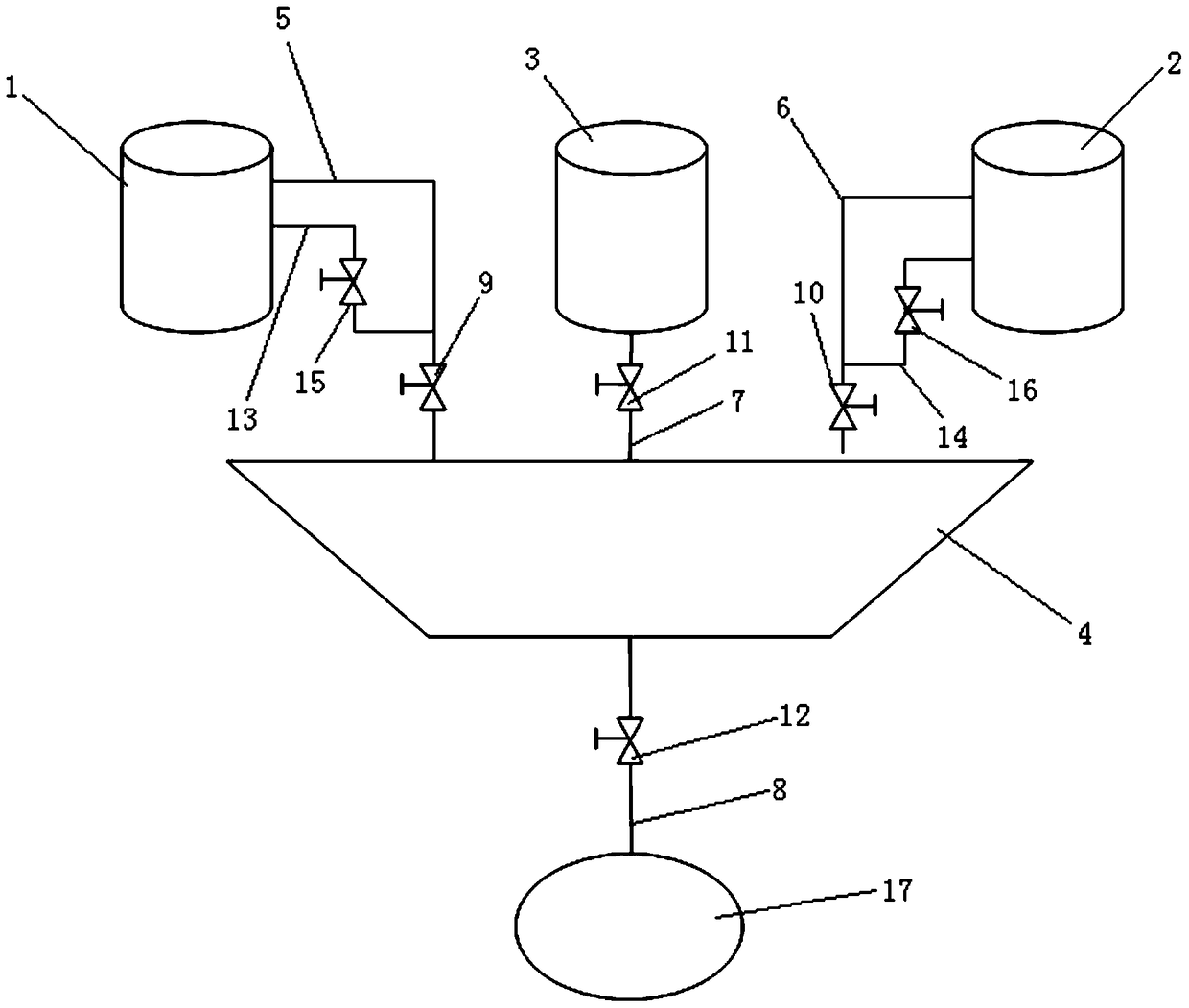

[0049] Output instructions to the control device through touch screen, mouse, keyboard or wireless remote control device. The control device receives instructions and outputs signals to the frequency conversion device to control the rotation of the rotating motor, thereby realizing the rotation of the spraying frame of the spraying equipment. At the same time, the control device outputs signals to the traveling motor to control the walking of the spraying frame of the spraying equipment. Next, the control device outputs a signal to the third electromagnetic valve, and the gas in the third gas storage device leads to the cleaning material output valve 11, so that the cleaning material output valve 11 is opened. The clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com