Spring pin complement device for live-line operation of power transmission line

A technology of live work and spring pins, which is applied in the direction of overhead line/cable equipment, pliers, manufacturing tools, etc., can solve the problems of inflexible rotation of the pin removal pliers, increase the difficulty of operation for operators, and offset the position of the pin removal pliers, etc., to achieve The effect of reducing live working time, improving working efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

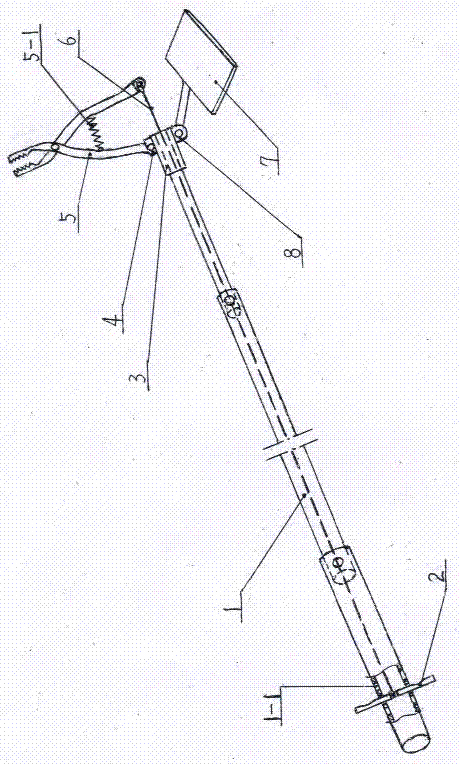

[0009] Examples, see attached figure 1 , On the upper end of the insulating telescopic rod 1 of the live work spring pin take-off device of the transmission line, a connection sleeve 3 is fixedly installed, and the clamp mounting seat 4 and the cardan shaft seat 8 are fixedly equipped with on the connection sleeve 3 respectively. The end observation mirror 7 is equipped with on the universal shaft seat 8, and the end observation mirror 7 can rotate 360 degrees. Compression spring 5-1 is housed between. The tail end of the other clamp handle of the clamp 5 is connected to the upper end of the clamp control stay cord 6, and the lower end of the clamp control stay cord 6 passes through the inner cavity of the insulating telescopic rod 1 and is fixed on the clamp control rod 2, and the clamp control The rod 2 is movably placed in the control rod slot 1-1 of the insulating telescopic rod 1.

[0010] The method of using the spring pin remover for live work on transmission lines ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap