Two-phase/three-phase mixed turn-on brushless direct-current motor PWM modulation method

A brushed DC motor and modulation method technology, applied in electronic commutator, torque ripple control and other directions, can solve the problem of less research on three-three conduction mode and two-three mixed conduction, and achieve rich speed control control way, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

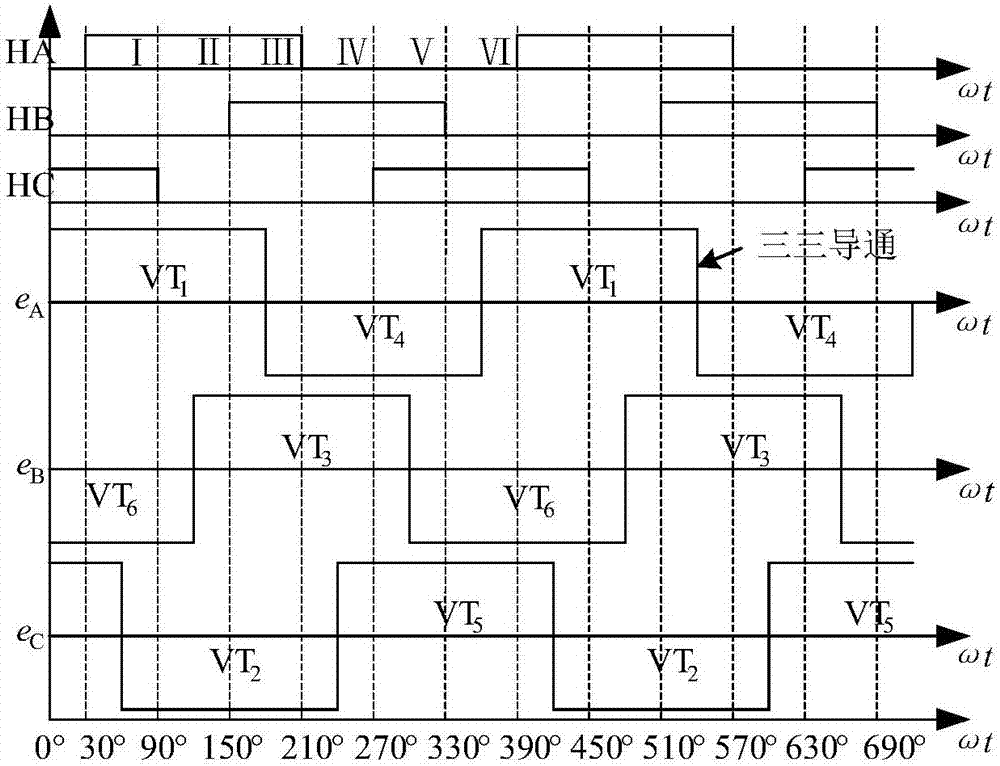

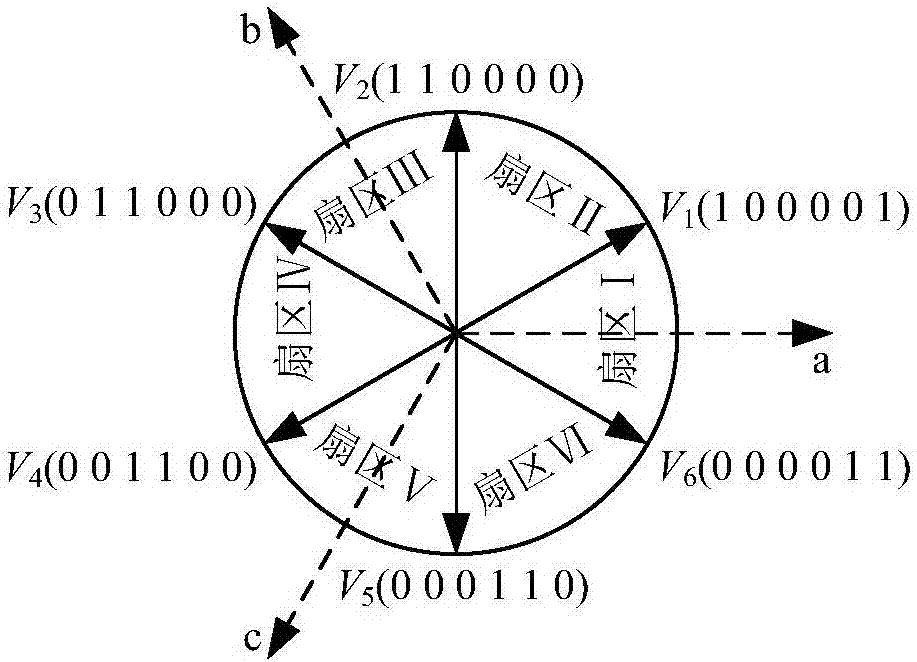

[0021] The purpose of the present invention is based on the existing brushless DC motor control system, using DSP chip and Hall signal, through the direct logic of Hall signal and the timing and operation of DSP, each switch tube is turned on for 150 electrical angles. A brushless DC motor two-three mixed conduction mode is formed, and then the conduction signal of the switch tube during the three-three conduction period of the motor is added to PWM modulation to form a new PWM-ON-PWM-ON-PWM modulation method.

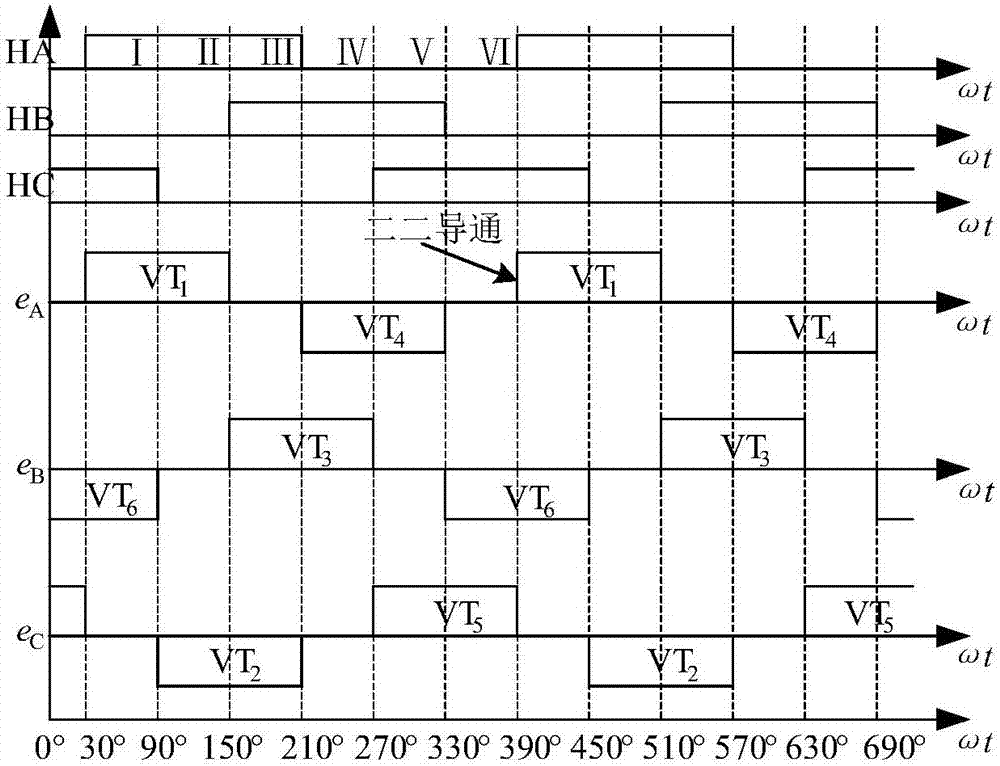

[0022] like figure 1 As shown, the two-to-two conduction of the brushless DC motor is a three-phase six-state. It means that only two power switch tubes are in the conduction state at any time. Every 60 degrees of electrical angle, the motor changes its working state once. Each switch The tubes are sequentially conducted through an electrical angle of 120 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com