Apparatus and method for the production of filters for cigarettes or other smoking articles

A filter and equipment technology, applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problems of diameter reduction and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

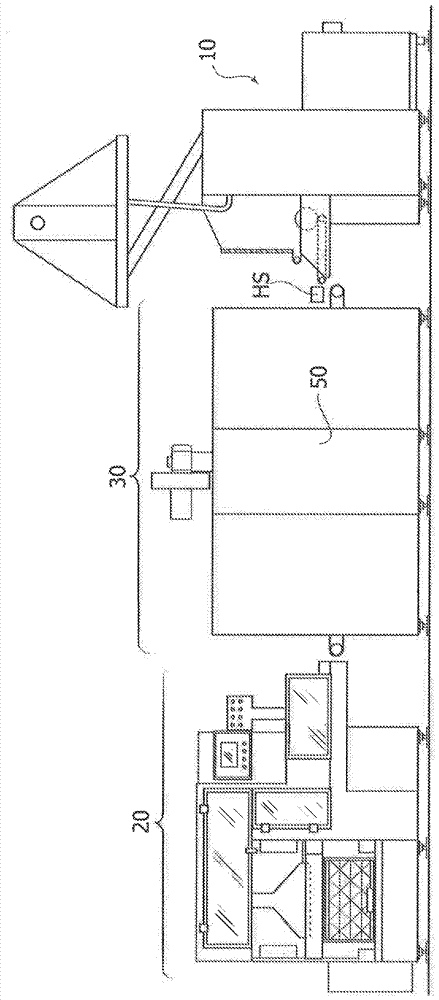

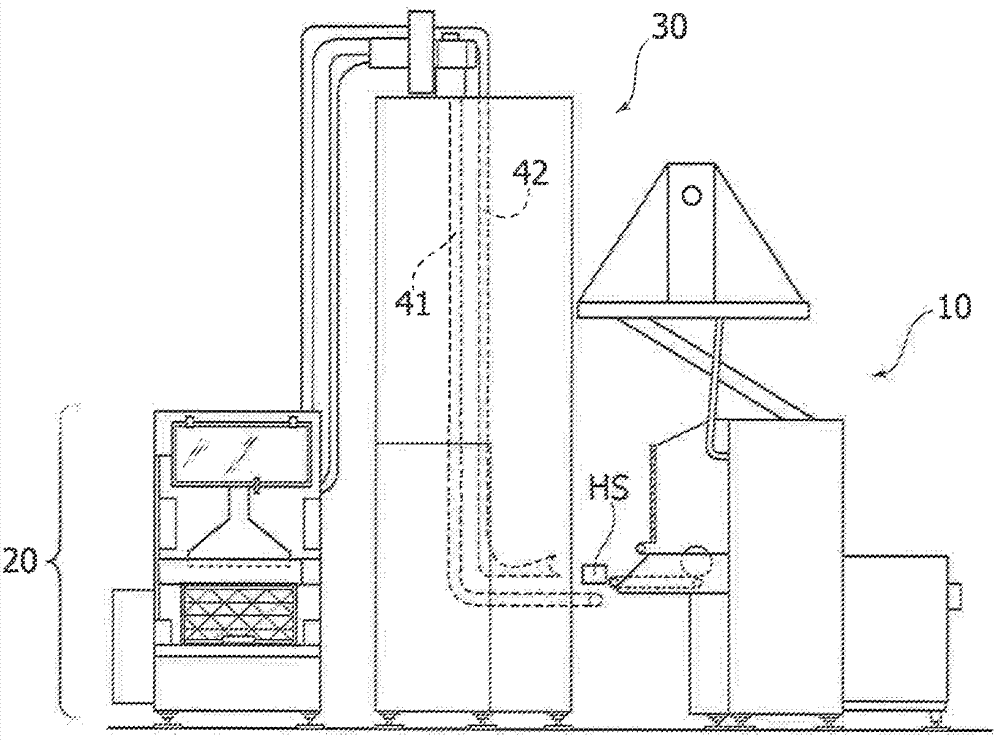

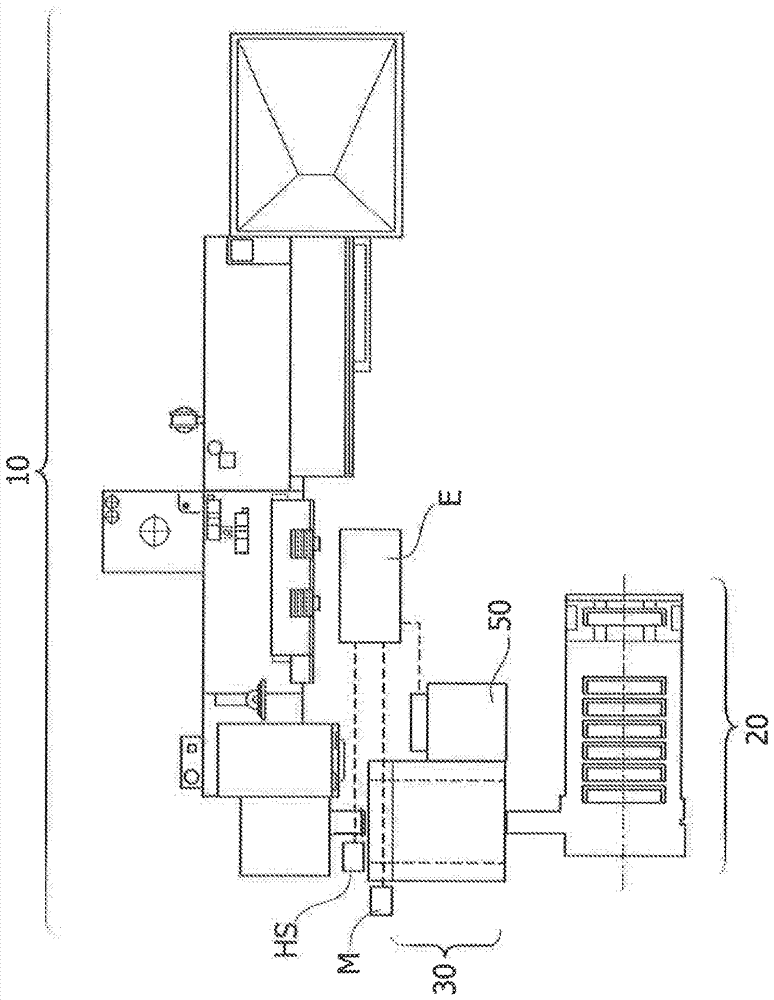

[0020] in the attached picture figure 1 , 2 Shows a production line for the production of filters for cigarettes or other smoking articles, comprising a first station 10 consisting of machines of known type containing fibers for the production of cellulose acetate with added plasticizers A filter making device that constitutes a filter. As already indicated, a machine of this type is described and shown, for example, in document EP 2 636 321 A1 of the same applicant. The machine shown in the drawings is that which has been placed on the market by the applicant under the name "MONO". However, also as already indicated, the invention is generally applicable to any type of machine for producing filters and to any type of filter.

[0021] In a special case of the above-mentioned known machine shown here, the machine comprises filter making means comprising: fiber bundles (which are selected from a large bundle of fibers) for processing and subsequent formation of cellulose acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com