Heat-sealing barrier paper

A heat-sealing and pre-coating technology, used in papermaking, packaging paper, paper coatings, etc., can solve problems such as restricting development and increasing costs, and achieve the effect of enhancing the barrier level, promoting online drying, and enhancing the barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Manufactured with a basis weight of 55g / m on a paper machine running at 400m / min 2 fiber carrier. The paper machine is equipped with a Yankee dryer placed before the size press.

[0088] The surface of the fibrous support is first smoothed and then treated on both sides by a sizer in-line with a pore-filling pigment composition comprising 100 parts by dry weight of kaolin (Cadam) of the Amazon Premium type, and Mixture of 20 parts by dry weight of Merifilm 104 starch (Tate & Lyle) and latex of type DL950 (Dow) relative to dry kaolin. When fully dry, the applied treatment is 5g / m 2 .

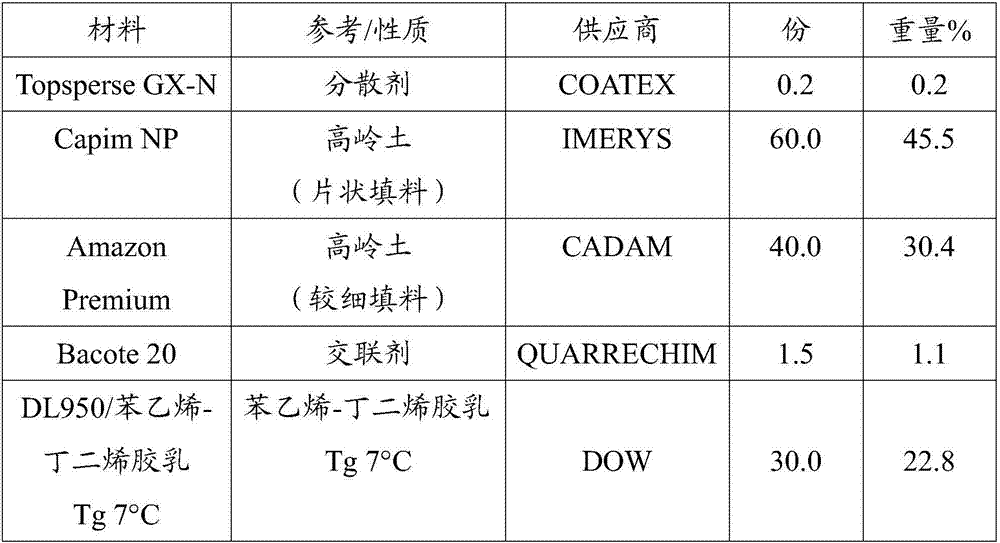

[0089] A Meyer rod coater is then used to coat a pre-coat formulation comprising a mixture of platy fillers and finer particulate fillers and a latex with a styrene-butadiene chemistry of Tg = 7°C (from DL950 from Dow Chemical) in an infrared oven followed by a hot air oven without contact. It was wound on rolls without further handling. The dry weight of the applied precoat is 7g / m ...

Embodiment 2

[0095] The surface of the fibrous support is first smoothed and then treated on both sides by a sizer in-line with a pore-filling pigment composition comprising 100 parts by dry weight of kaolin (Cadam) of the Amazon Premium type, and Mixture of 20 parts by dry weight of Merifilm 104 starch (Tate & Lyle) and latex of type DL950 (Dow) relative to dry kaolin. When fully dry, the applied treatment is 5g / m 2 .

[0096]A Meyer rod coater was then used to coat a formulation comprising a mixture of platy fillers and finer particulate fillers and a latex with styrene-butadiene chemistry (DL950 from Dow Chemical) with a Tg = 7°C. ), dried without contact in an infrared oven, then in a hot air oven. It was wound on rolls without further handling. The dry weight of the applied precoat is 7g / m 2 And its formula is given in the following table:

[0097]

[0098] 95% by weight of the Hydrocarb 95 has a particle size of less than 2 microns measured according to the ISO 13317-3 SediGr...

Embodiment 3

[0101] Paper was produced on-line under the same conditions as in Example 1. But after depositing the precoat, a cover layer consisting of a dispersion of PVdC copolymer (Diofan A297 from Solvay) was applied in-line and dried without contact in an infrared oven and then in a hot air oven. It was wound on mandrels without further handling and no blocking was observed between turns. The dry weight of the covering layer is 6.5g / m 2 .

[0102] The barrier to water vapor was measured by a Mocon Permatran 3 / 61 machine at 38°C and 90% relative humidity according to ASTM F1249 standard. The barrier to water vapor is 21.0±2.4g / m 2 / 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Water vapor permeability | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com