Spark plug and method for producing a spark plug

A spark plug and center electrode technology, applied in the field of spark plug manufacturing, can solve the problem of high spark plug wear, and achieve the effects of reducing heat dissipation and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

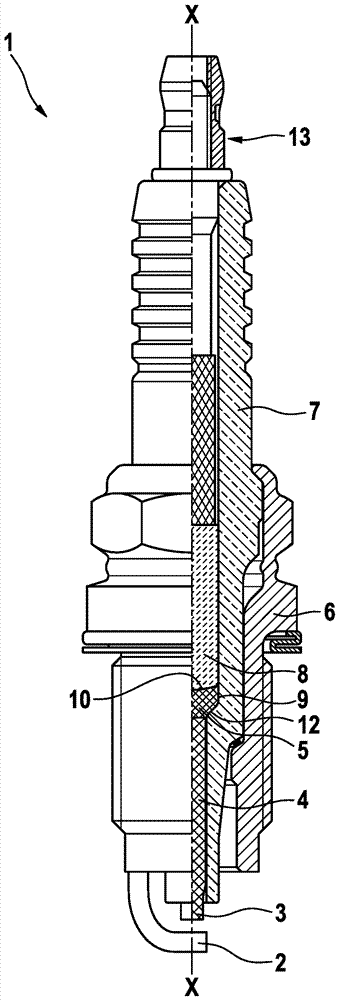

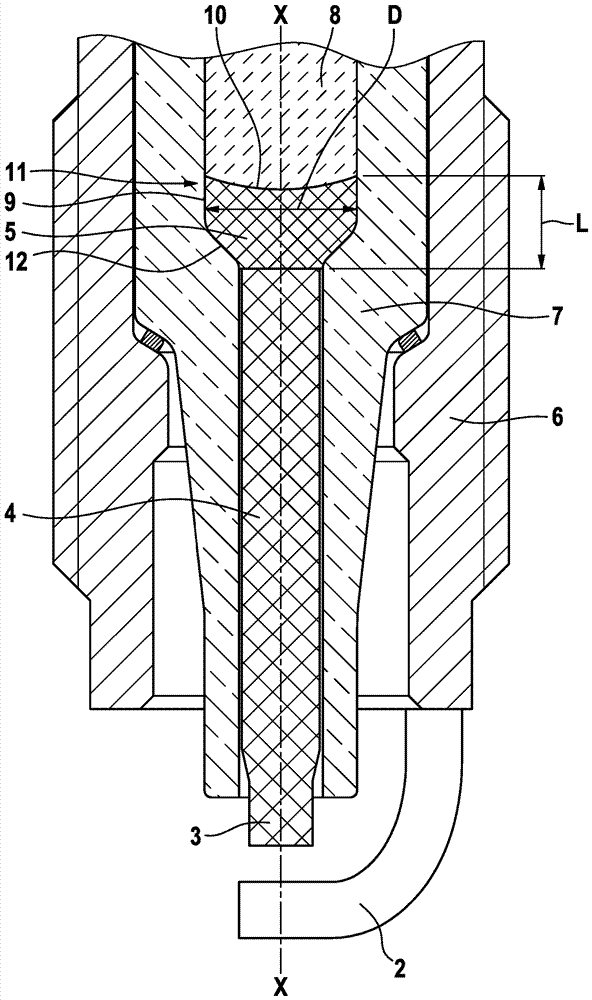

[0023] As can be seen from 1 , spark plug 1 comprises a ground electrode 2 and a center electrode 3 . The ceramic insulator 7 is arranged in such a way that the center electrode 3 protrudes slightly from the insulator 7 in a known manner. The center electrode 3 is produced from one material, but can of course also have a core-sheath structure, for example with a sheath of a material containing nickel and a core of a material containing copper, which improves the connection from the base of the center electrode towards the combustion chamber to the insulator. 7 on heat transport. Furthermore, noble metal pins can be provided on the combustion chamber side for generating the spark plasma.

[0024] The insulator 7 itself is partially surrounded by the housing 6 . Reference numeral 13 designates an electrical connection region of spark plug 1 . An electrically conductive connection to the central electrode 3 is provided from the electrical connection region 13 via the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com