Method for individualized customization of sacrum reconstruction plate by 3D printing and sacrum reconstruction plate

A 3D printing, sacral technology, applied in the direction of bone implants, additive processing, etc., can solve the problems of difficult to meet the requirements of doctors, long design cycle of customized prostheses, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

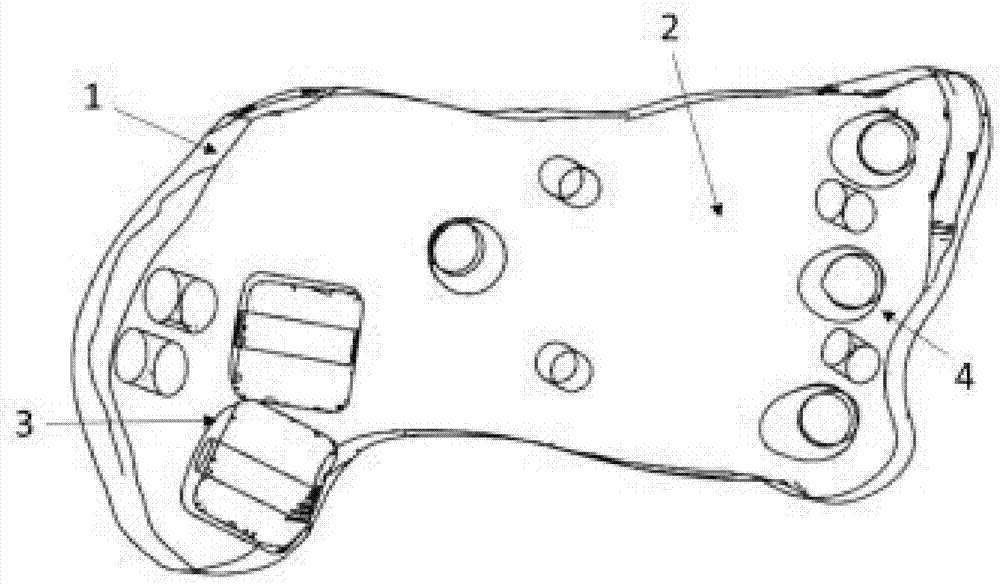

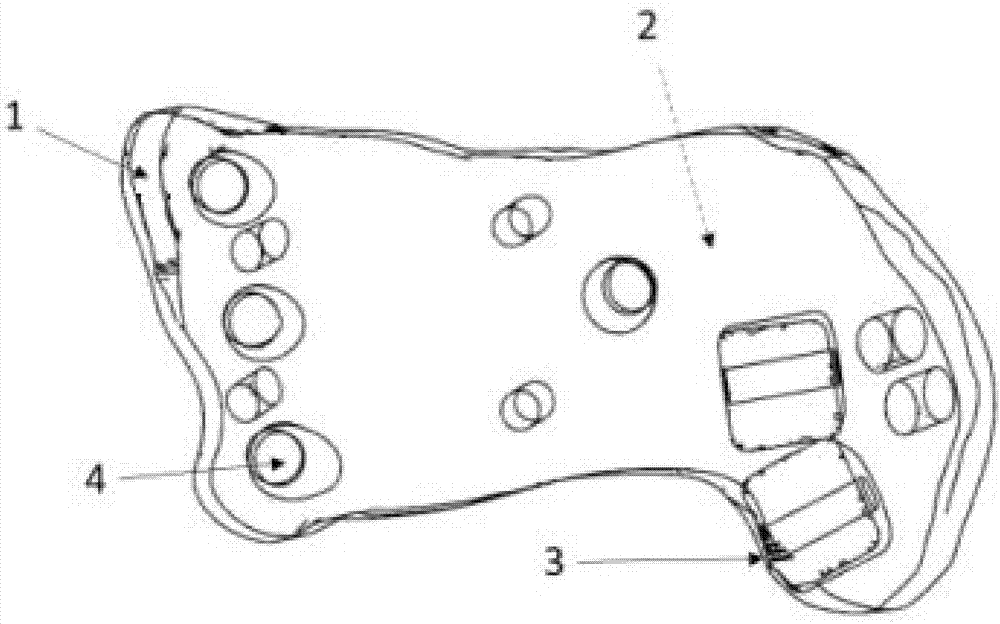

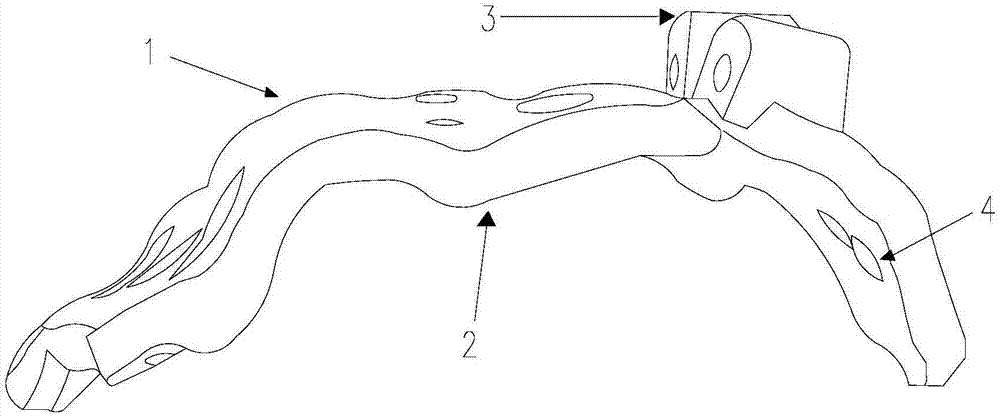

[0051] The 3D printed individualized customized sacral reconstruction plate in this embodiment includes a bionic sacral fitting plate for fitting and installing on the sacrum. The shape of the bionic sacral fitting plate is formed by mimicking the back of the human sacrum, and the bionic sacral fitting plate and The sacrum fitting surface is provided with a metal mesh bone fitting surface, wherein the area of the metal mesh bone fitting surface is at least 1 / 3 to 1 / 2 of the overall area of the bionic sacral fitting plate. The plywood is provided with fixing nail holes and a base for fixing the pelvic prosthesis;

[0052] Wherein, the sacrum reconstruction plate is prepared by the method of 3D printing an individualized customized sacrum reconstruction plate in the above embodiment.

[0053] The thickness of the bionic sacral bonding plate is 5 mm; the thickness of the metal mesh bone bonding surface is 1 mm.

[0054] The length and width of the biomimetic sacral bonding plate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com