Full-automatic two-side-surface saw blade grinding machine

A fully automatic, grinding machine technology, applied in metal sawing equipment, tool trimming of sawing machine devices, metal processing equipment, etc., can solve the problem of working time, work efficiency, work stability, inability to change gears automatically, and affect processing accuracy, etc. problems, to achieve the effect of reducing the cost of use and maintenance, improving the grinding accuracy and sharpness of the knife edge, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Convention: The synchronous movement connection in this application refers to the connection that the connected parts can perform synchronous movement; in this application, reference words such as left, right, front, and back are used to refer to the sliding block of the knife setting device and the saw blade fixing mechanism. The description is only used to distinguish the same or similar components or components, and does not constitute a limitation on the structure or function of related components or components.

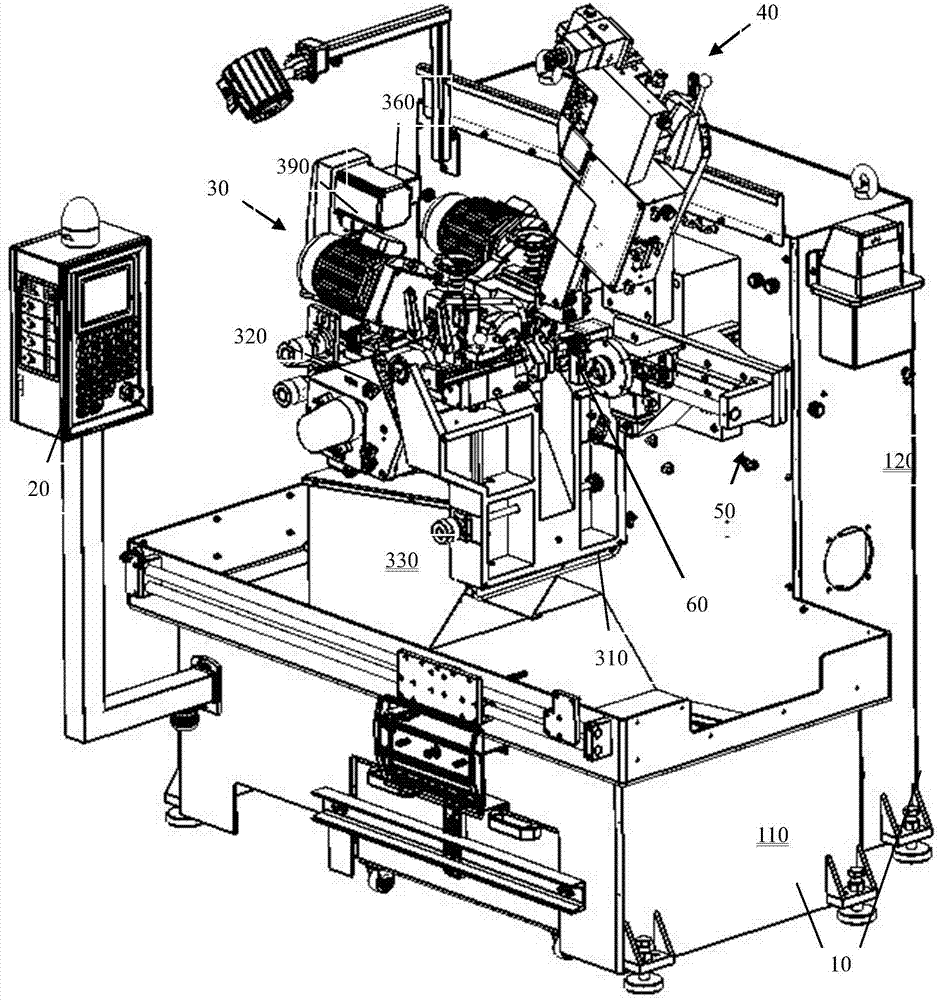

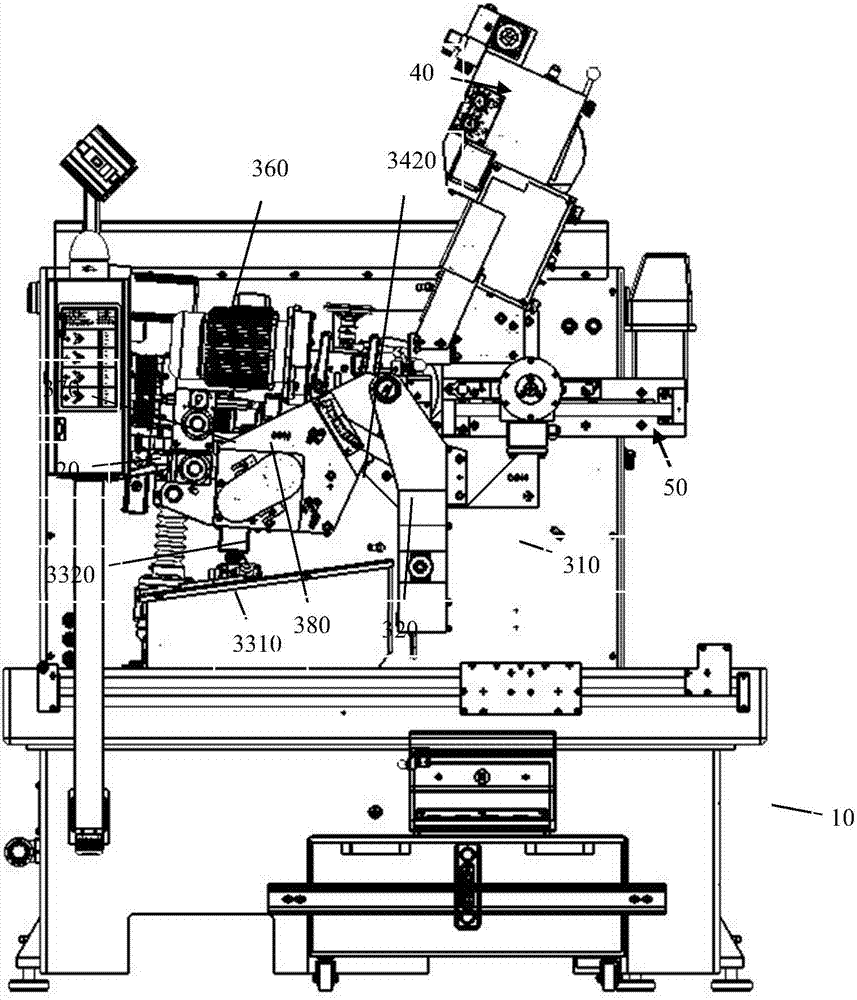

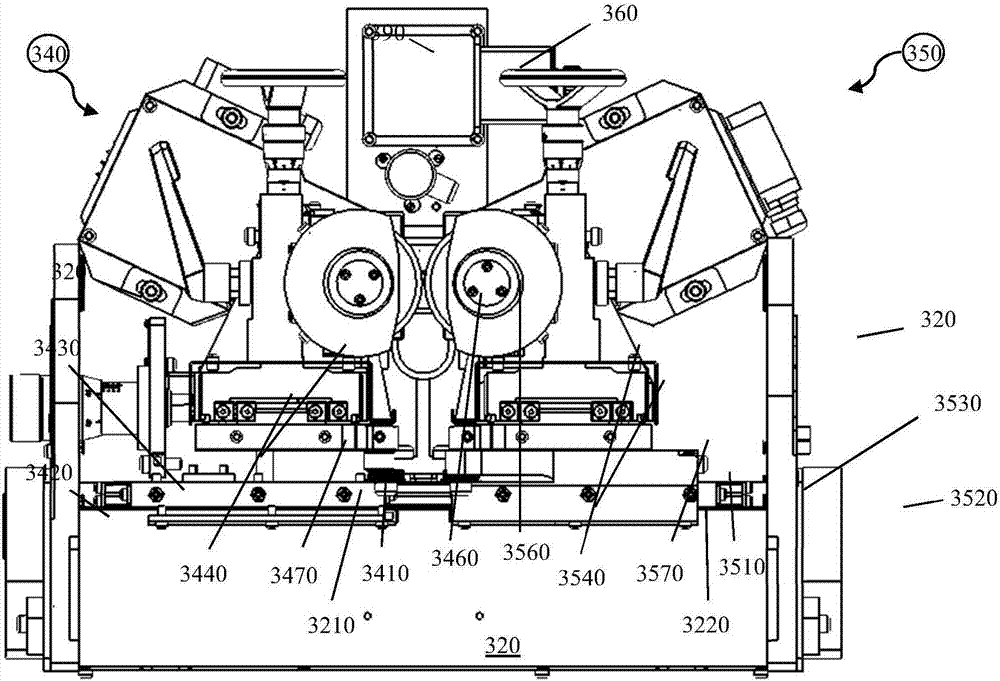

[0036] The fully automatic double-sided saw blade grinding machine disclosed in the present invention includes a machine bed 10 and an electric control system 20, and the machine bed 10 is provided with a grinding device 30, a gear shifting mechanism 40, a saw blade fixing mechanism 50, and a saw blade clamping mechanism 60 The machine bed 10 is used to integrate and carry other components or components, the saw blade fixing mechanism 50 is used to fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com