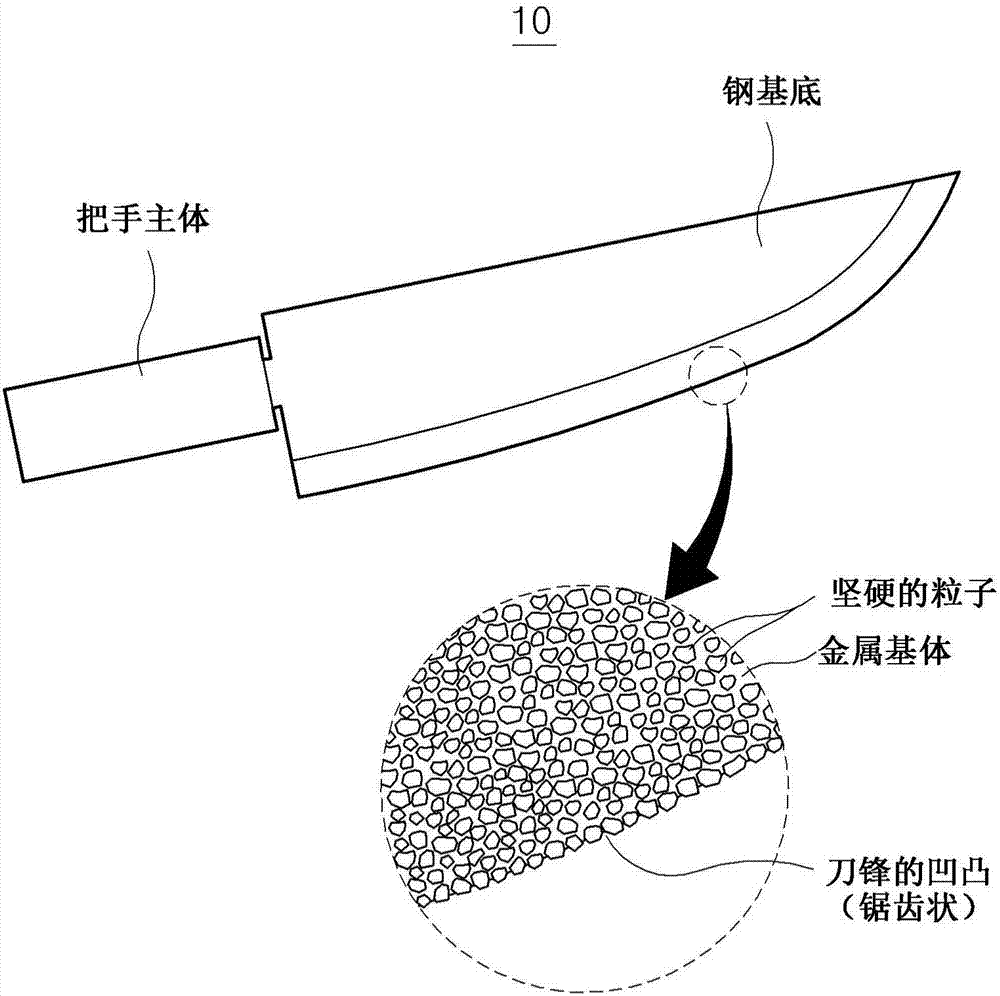

Blade for cutting instrument having edge of micro-sized uneven form, and cutting instrument having blade

A cutting tool and cutting edge technology, applied in the field of cutting instruments, can solve the problems of wear of the protrusion of the blade, difficulty in providing cutting feeling, decreased cutting performance, etc., and achieve the effect of maintaining cutting force, excellent cutting feeling, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

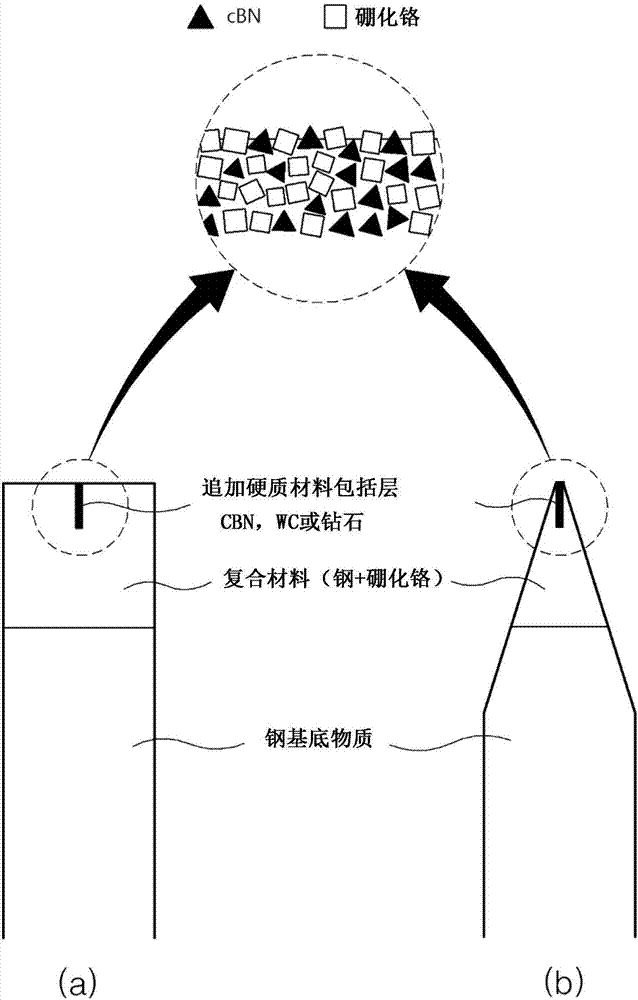

[0045] Usually, it can be produced by a powder metallurgy method in which hard particles such as tungsten carbide (WC) are added to a molten metal, stirred and then cooled, or hard particles and particles constituting a metal matrix are mixed and then sintered.

[0046] However, in the examples of the present invention, a special point is that a substance of a specific composition alloyed in a molten state is used.

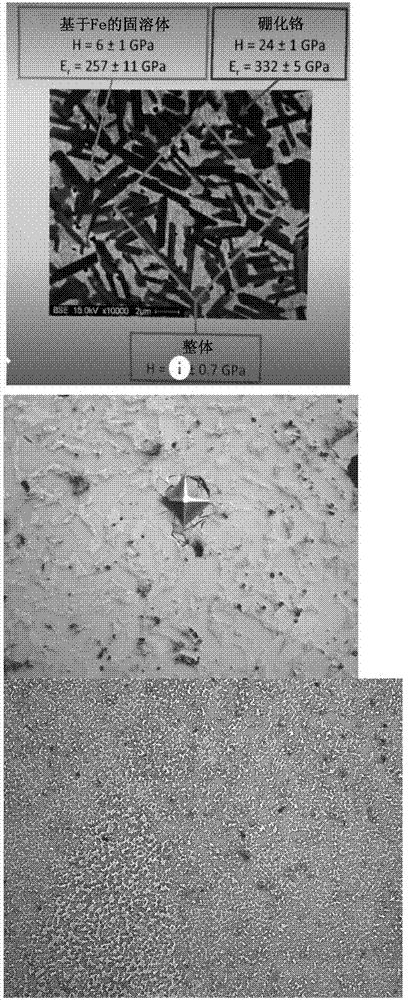

[0047] The composition range of the alloy used in the example of this invention has the composition of the following Table 1.

[0048] 【Table 1】

[0049] Element Fe Cr Si B Content (mass%) 45~55 40~50 Below 10 5 or less

[0050] When an alloy having the above-mentioned composition is melted and then cast and left to cool, a composite material is formed in which chromium (Cr) included in the alloy reacts with boron (B) during solidification to form boride Chromium (Crboride), and the rest form the matrix structure of stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com