Infusion bag automatic turnover and sorting system

A sorting system and automatic inversion technology, applied in the direction of packaging automatic control, transportation and packaging, packaging, etc., can solve the problems of overlapping, slow sorting speed, low sorting efficiency, etc., to reduce sorting errors and achieve purification. Handling and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

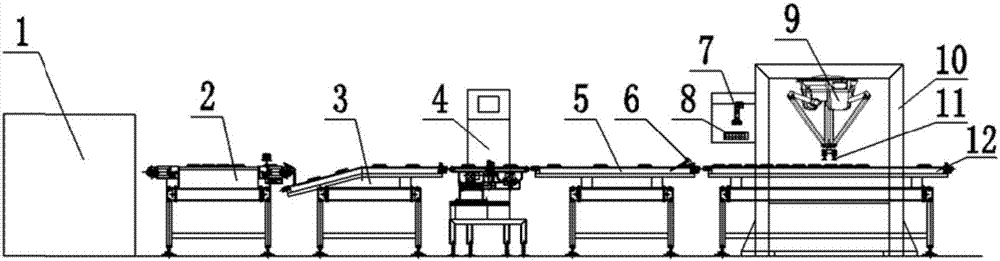

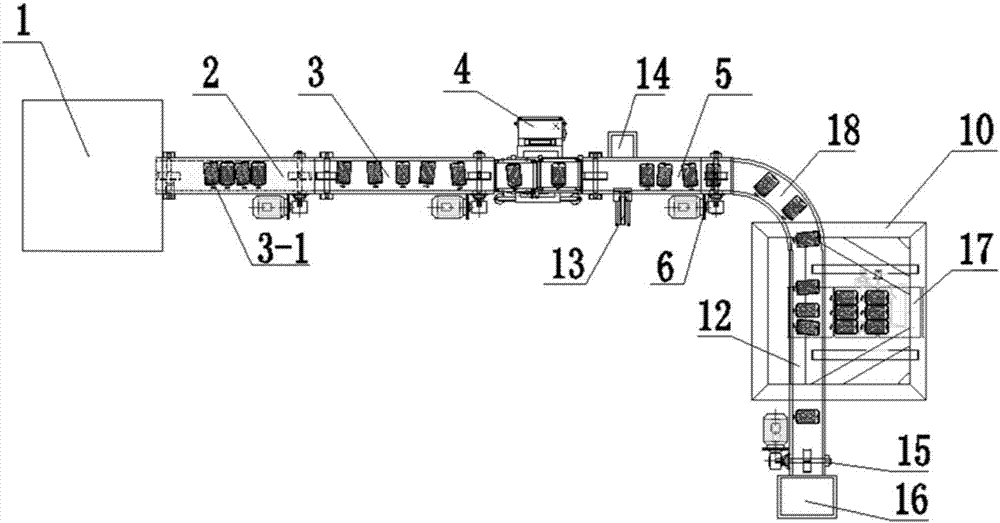

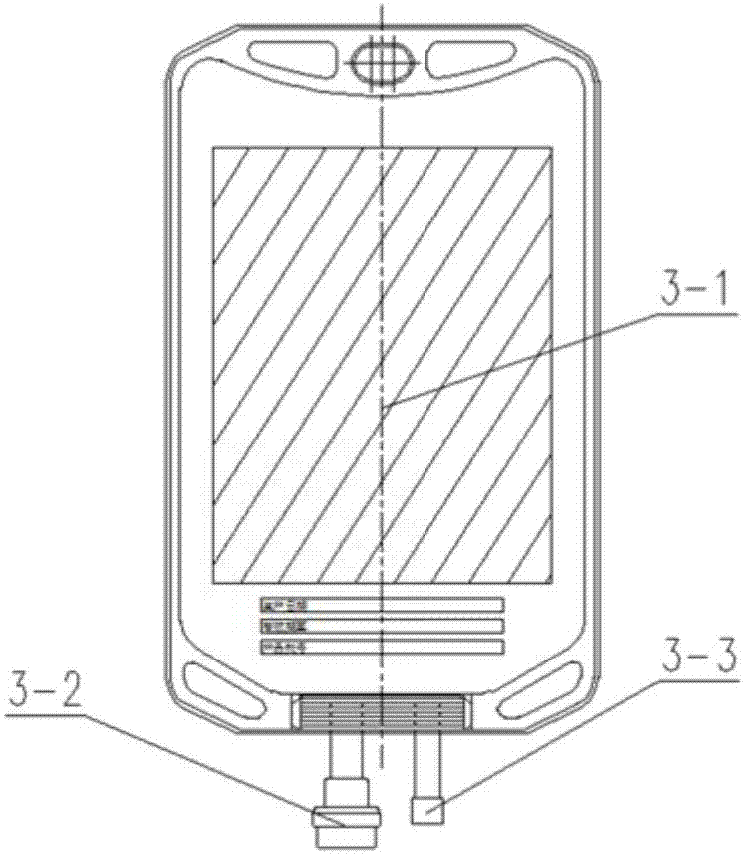

[0043] An embodiment of the present invention provides an automatic flip sorting system for infusion bags, such as figure 1 and figure 2 The infusion bag automatic flip sorting system mainly includes a first conveying line 2, a second conveying line 3, an online re-inspection scale 4, a third conveying line 5, a flattening device 6, a rejecting device 13, a first receiving hopper 14, Visual device 7, industrial light source 8, robot 9, frame 10, fixture, suction cup 11, encoder 15, fourth conveying line 18, fifth conveying line 12 and second hopper 16; the relationship between the above components as follows:

[0044] Wherein the first conveying line 2, the second conveying line 3, the third conveying line 5, the fourth conveying line 18 and the fifth conveying line 12 are arranged in sequence, and the fourth conveying line 18 is a curved conveying line, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com