High-intensity and high-reactivity gasified coke production method using high-proportion long flame coal

A high-reactivity, long-flame coal technology, applied in coking ovens, special forms of dry distillation, petroleum industry, etc., can solve the problems of reducing production costs, high reactivity, low coking coal dosage, etc., to expand production flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) According to the national standard method, the gel layer thickness of Shenmu long flame coal (SMC), Wuhai gas coal (QM-1) and Taiyuan fat coal (FM-1) were determined to be 0, 11, 32 respectively;

[0024] (2), according to the additivity of the Y value of a single coal, first draw up the ratio of the single coal when the Y value of the blended coal is greater than 10; The proportioning ratio of coal and fat coal is 40wt%, 35wt%, 25wt% respectively;

[0025] (3), single coal is pulverized respectively, and by weight percent, the particle size distribution of SMC is <1mm ratio 25%, 1-2mm ratio 25%, 2-3mm ratio 50%; The particle size distribution of QM-1 is The proportion of <1mm is 15%, the proportion of 1-2mm is 30%, and the proportion of 2-3mm is 55%. The particle size distribution of FM-1 is <0.2mm and the proportion is more than 90%

[0026] (4), coal types of different particle sizes are mixed, and add moisture 10wt%;

[0027] (5) After mixing evenly, tamp the...

Embodiment 2

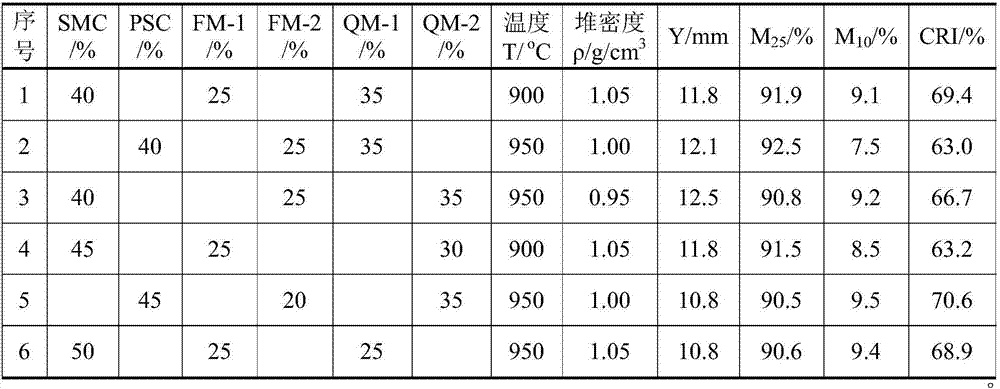

[0030] Pingshuo long-flame coal (PSC), Wuhai gas coal (QM-1) and Wuhai fat coal (FM-2) used in this example have gelatinous layer thicknesses of 0, 11, and 33 respectively, and their dosages 40wt%, 35wt%, and 25wt%, respectively. The particle size distribution of PSC is 25% of 3 , the heating rate is 5°C / min, and the water addition amount is 9wt%. The Y value of the blended coal, coke strength and reactivity index are shown in Table 1. All the other are with embodiment 1.

Embodiment 3

[0032] The colloid layer thicknesses of Shenmu long-flame coal (SMC), Shenmu gas coal (QM-2), and Wuhai fat coal (FM-2) used in this embodiment are 0, 12, and 33 respectively, and their dosages are respectively 40wt%, 35wt%, 25wt%. The particle size distribution of SMC is 25% of 3 , the heating rate is 4°C / min, and the water addition amount is 11wt%. The Y value of the blended coal, coke strength and reactivity index are shown in Table 1. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com