Finishing method for wool fabric by using keratinase and chitosan

A technology of keratinase and chitosan, applied in the biochemical treatment of enzymes/microorganisms, animal fiber, fiber treatment, etc., can solve the problem of low grafting efficiency, and achieve improved bonding fastness, mild conditions and good antibacterial properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

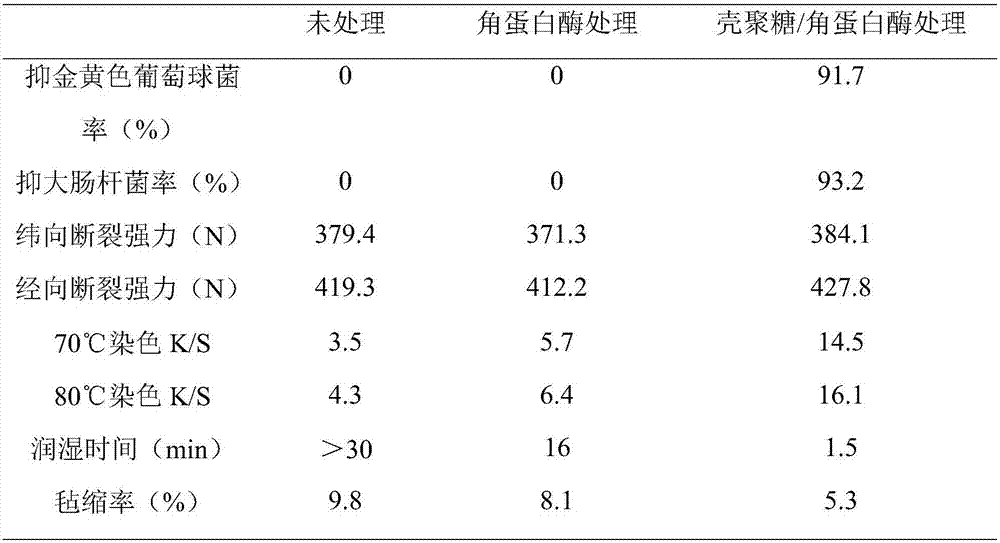

Embodiment 1

[0026] Embodiment 1: The wool fabric selected in this example is all-wool gabardine, and the selected mercapto group introducing agent is cysteine.

[0027] (1) Chitosan sulfhydryl modification process: Dissolve 0.5g chitosan in 50mL distilled water containing 0.348g 1-hydroxybenzotriazole, stir well and add cysteine and 1-(3-dimethyl Aminopropyl)-3-ethylcarbodiimide salt, the mol ratio of chitosan / cysteine / 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt is 1:2:1, then use 10mol / L sodium hydroxide solution to adjust the pH to 5, react at room temperature in the dark for 5 hours, precipitate the product with absolute ethanol, extract with acetone, vacuum-dry at 50°C, and store at 4°C;

[0028] (2) Wool reduction pretreatment process: the wool fabric is extracted and degreased with acetone at 76°C, washed with water, dried in an oven at 50°C, treated with keratinase, the bath ratio is 1:50, and the reaction time is 10h. The reaction temperature is 45°C, the dosage of kerat...

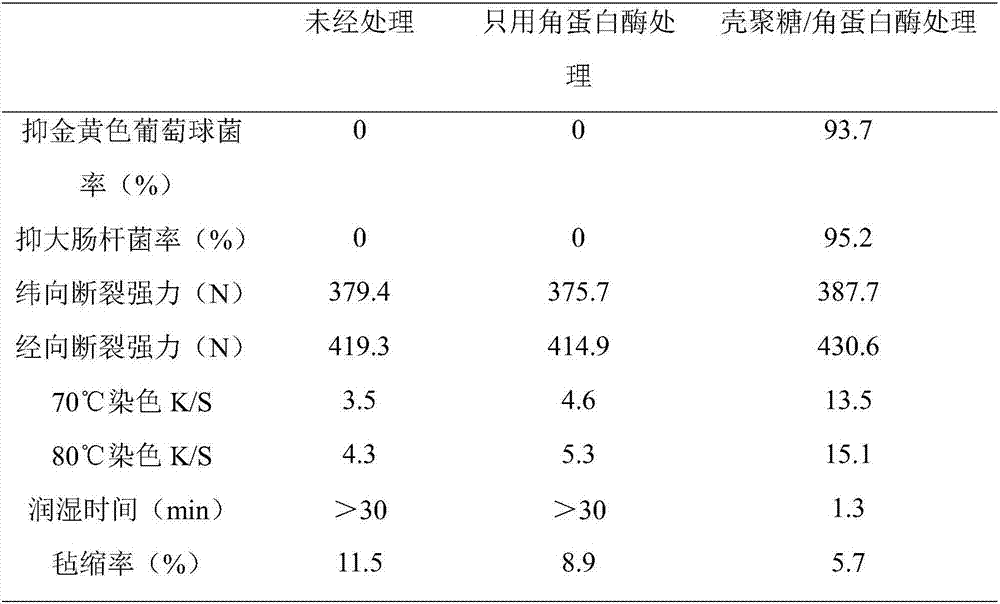

Embodiment 2

[0034] Embodiment 2: the selected wool fabric of this example is full wool gabardine, and the selected mercapto group introducing agent is thioglycolic acid

[0035] (1) Chitosan sulfhydryl modification process: dissolve 0.5g chitosan in 50mL distilled water containing 0.348g 1-hydroxybenzotriazole, stir well and add thioglycolic acid and 1-(3-dimethylaminopropyl Base)-3-ethylcarbodiimide salt, the mol ratio of chitosan / mercaptoacetic acid / 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt is 1:2: 1. Then use 10mol / L sodium hydroxide solution to adjust the pH to 6, react at room temperature in the dark for 5 hours, precipitate the product with absolute ethanol, extract with acetone, vacuum-dry at 40°C, and store at 4°C;

[0036] (2) Wool reduction pretreatment process: the wool fabric is extracted and degreased with acetone at 76°C, washed with water, dried in an oven at 50°C, treated with keratinase, the bath ratio is 1:50, and the reaction time is 5h. The reaction temperatu...

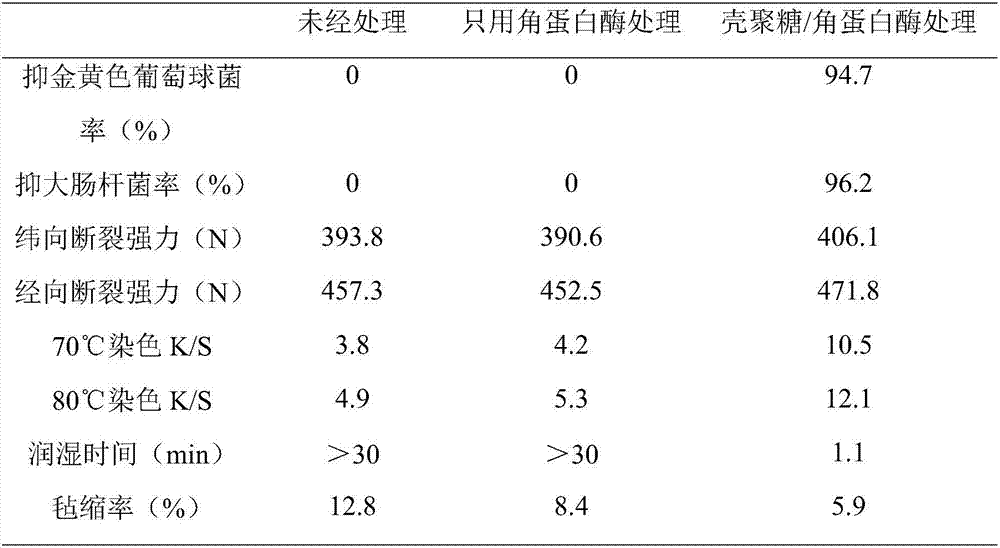

Embodiment 3

[0042] Embodiment 3: the selected wool fabric of this example is all-wool women's clothing, and the selected mercapto group introducing agent is N-acetyl-L-cysteine

[0043] (1) Chitosan sulfhydryl modification process: dissolve 0.5g chitosan in 50mL distilled water containing 0.348g 1-hydroxybenzotriazole, stir well and add N-acetyl-L-cysteine and 1- (3-Dimethylaminopropyl)-3-ethylcarbodiimide salt, chitosan / N-acetyl-L-cysteine / 1-(3-dimethylaminopropyl)-3 - The molar ratio of ethyl carbodiimide salt is 1:2:1, then adjust the pH to 7 with 10mol / L sodium hydroxide solution, react at room temperature in the dark for 3 hours, the product is precipitated with absolute ethanol, extracted with acetone, 50°C Vacuum dried and stored at 4°C;

[0044] (2) Wool reduction pretreatment process: the wool fabric is extracted and degreased with acetone at 76°C, washed with water, dried in an oven at 50°C, treated with keratinase, the bath ratio is 1:50, and the reaction time is 5h. The re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap