Prefabricated tubular pumping house structure

A pumping station and cylinder technology, which is applied in the field of prefabricated pumping station cylinder structure, can solve the problems of not being able to meet the requirements of mass production, complex molding process of the cylinder structure, and difficult quality control, so as to achieve easy control of quality and satisfactory structural strength , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

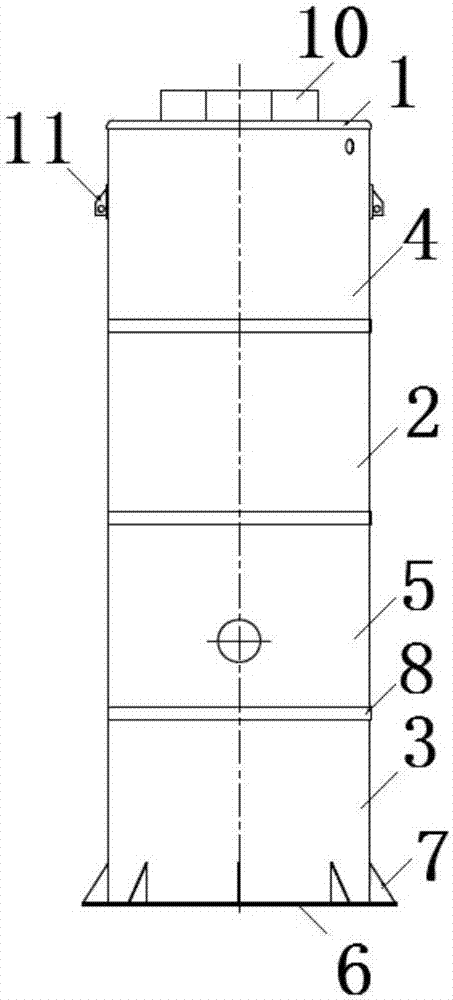

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

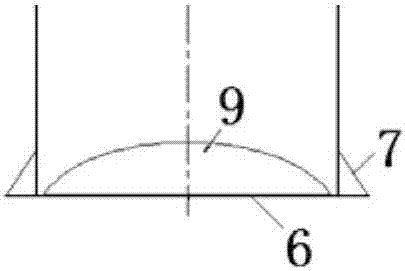

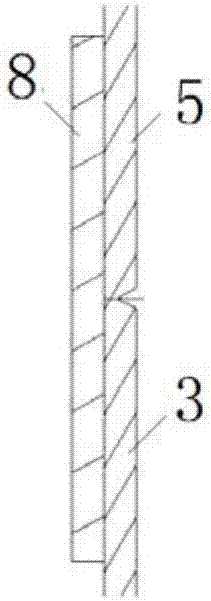

[0024] Such as Figure 1 to Figure 3 As shown, the shell structure of the prefabricated pumping station includes the shell body, the bottom plate 6 of the pumping station, and the head 1. The body of the shell body is a cylindrical structure, the lower end of the body body is welded on the bottom plate 6 of the pumping station, and the head 1 is welded At the upper end of the barrel body, the barrel body is a segmented structure, which includes a group of barrels that are segmented up and down. The corresponding ends of the adjacent barrels are aligned up and down, and the outer hoops at the joints of adjacent barrels are reinforced with steel. Belt, the reinforced steel belt is welded to the cylinder body.

[0025] The cylinder body is a segmented structure, and the adjacent cylinder bodies a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com