Nitrogen inhibition vapor fog preparation method and system for preventing spontaneous combustion of coal in underground goaf

A technology for spontaneous combustion of coal and goaf, which is applied in mining equipment, dust prevention, earthwork drilling, etc., to achieve the effect of improving site applicability, good spatial diffusion, and strong intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

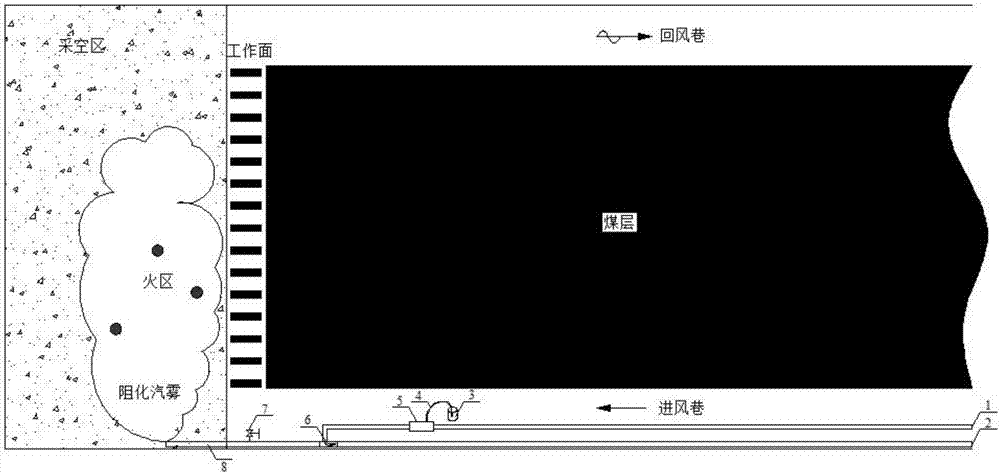

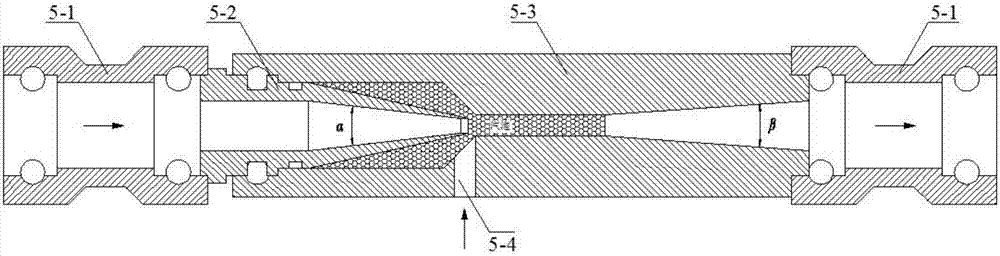

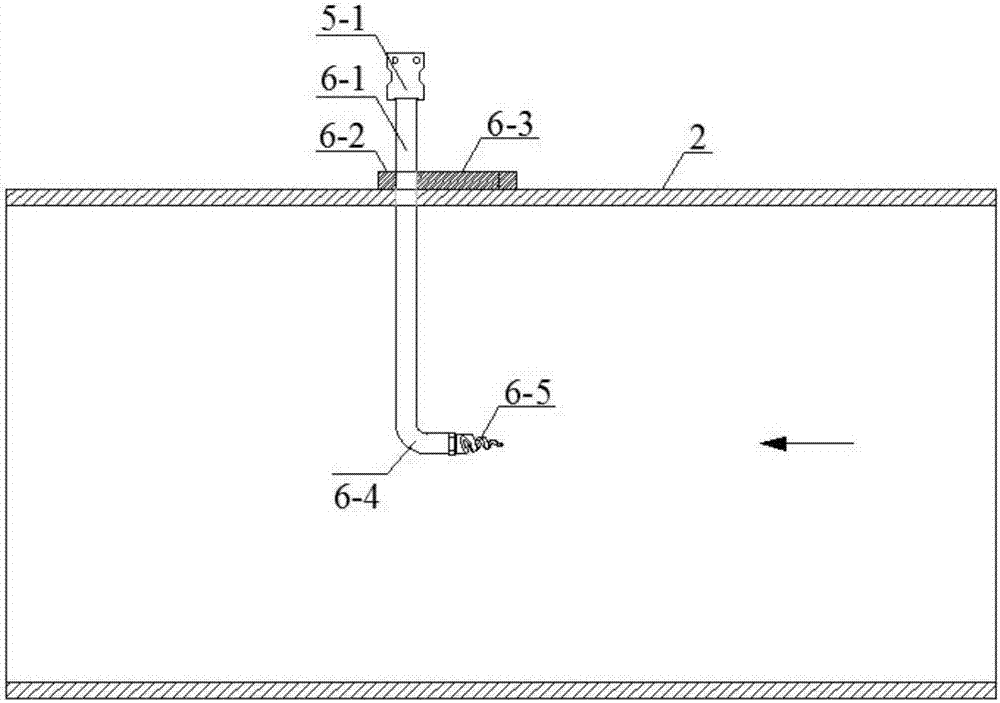

[0018] Such as figure 1 As shown, the present invention proposes a nitrogen gas resistance vapor mist preparation system for preventing coal spontaneous combustion in underground gobs, the system includes a water supply pipeline (1), a nitrogen injection pipeline (2), and a resistance chemical storage tank (3) , suction hose (4), inhibitor adding device (5), spiral atomization device (6), observation hole (7) and perfusion pipeline (8); among them, water supply pipeline (1) and nitrogen injection The pipeline (2) directly uses the existing nitrogen injection pipeline and water supply pipeline in the underground coal mining face, the inhibitor adding device (5) is installed on the water supply pipeline (1), and the inhibitor liquid storage tank (3 ) is connected with the inhibitor adding device (5) through the suction hose (4), the inlet of the spiral atomization device (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com