Combustion Diagnosis Method of Heating Furnace Based on Temperature Distribution

A technology of temperature distribution and diagnosis method, which is applied in the directions of temperature recording method, radiation pyrometry, hot spot detection, etc., can solve the problem of flame feature extraction, flame feature analysis is difficult to achieve, the spatial temperature distribution and flame gradient distribution cannot be measured, and cannot be effectively Judging the combustion state of the heating furnace and other issues, to achieve the effect of solving technical bottlenecks and real-time monitoring of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

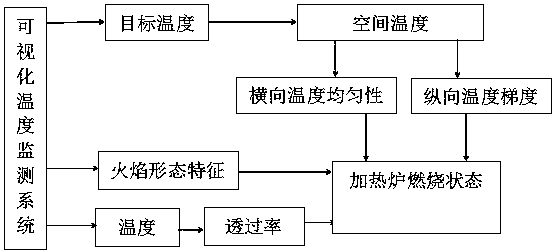

[0022] Such as figure 1 As shown, the present invention provides a heating furnace combustion diagnosis method based on temperature distribution. The radiation transmittance of high-temperature flue gas is calculated according to the target infrared radiation received by the detector pixel in the heating furnace under the same temperature condition. The relationship between the change of radiation transmittance of high-temperature flue gas in the infrared band and the combustion efficiency of natural gas, and the combination of flame shape characteristics to directly reflect the combustion state in the heating furnace; use the infrared temperature measuring device to measure the target surface temperature of the heating furnace as a boundary condition to solve the problem Calculate the space temperature in the heating furnace, obtain the horizontal space temperature distribution and longitudinal temperature gradient of the heating furnace through the space temperature, judge th...

Embodiment 2

[0025] Study the radiation spectrum of carbon dioxide and water vapor in the high-temperature flue gas at the burner of the heating furnace, find the radiation window with a large infrared radiation transmittance, and combine the spectral response characteristics of the near-infrared detector to determine the optimal filtering center wavelength, so as to obtain the maximum flame form. The flame shape directly reflects the air distribution of the burner. If the air distribution to the burner is good, the transmittance is high, the combustion efficiency is high and the flame is invisible; if the air distribution to the burner is not good, the transmission rate is low, the combustion efficiency is low, and the flame is visible and invisible. Sway with the wind.

[0026] Use the infrared temperature measuring device to measure the target surface temperature of the heating furnace. Since the target to be measured is in a high-temperature combustion furnace environment, there are to...

Embodiment 3

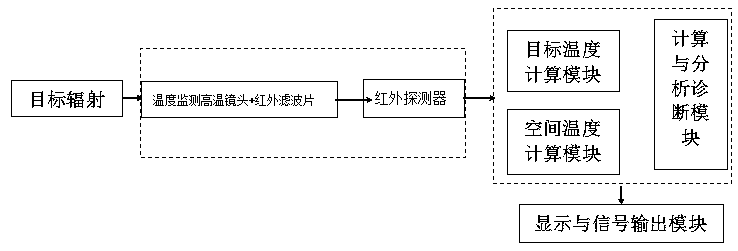

[0035] Such as figure 2 As shown, the infrared temperature measuring device is used to measure the target surface temperature of the heating furnace. The infrared temperature measuring device includes a temperature monitoring high temperature lens, an infrared filter, an infrared detector and a calculation and analysis diagnosis module connected in sequence. The infrared detection The infrared monitoring probe of the detector is directly installed on the side wall or top of the furnace body through a sealed connection mechanism. The infrared radiation signal inside the furnace first passes through the temperature monitoring high-temperature lens, and then forms an electrical signal on the infrared detector after being filtered by an infrared filter. The data is analyzed and processed through the calculation and analysis diagnosis module through the cable transmission to the industrial computer. The calculation and analysis diagnosis module calculates the target surface tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com