A kind of low-temperature denitrification catalyst with strong anti-sulfur and anti-water performance and preparation method thereof

A low-temperature denitrification and catalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low-temperature denitrification catalyst activity decline, and improve low-temperature denitrification activity, high-low temperature denitrification activity, The effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

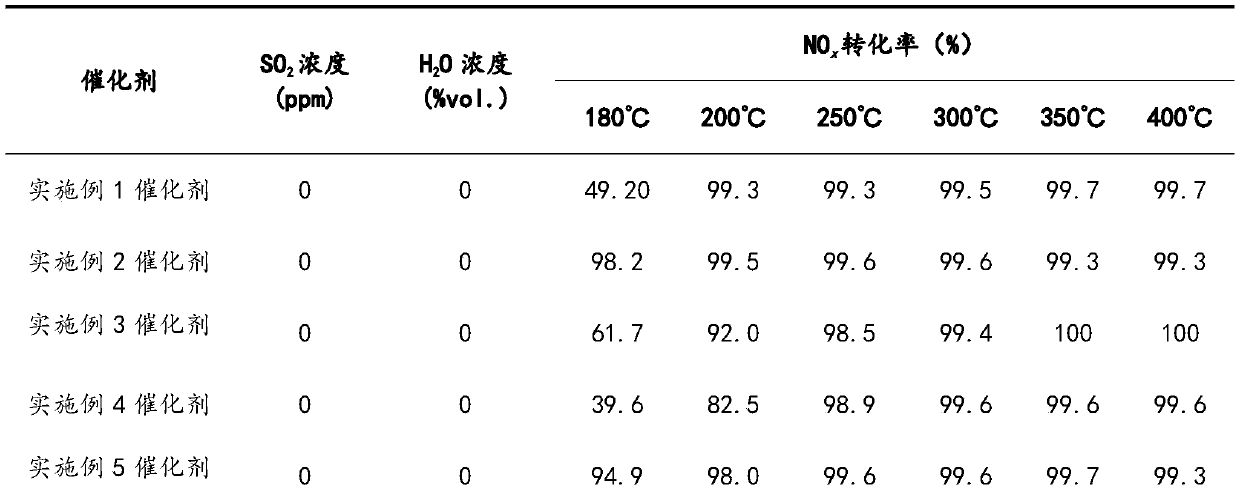

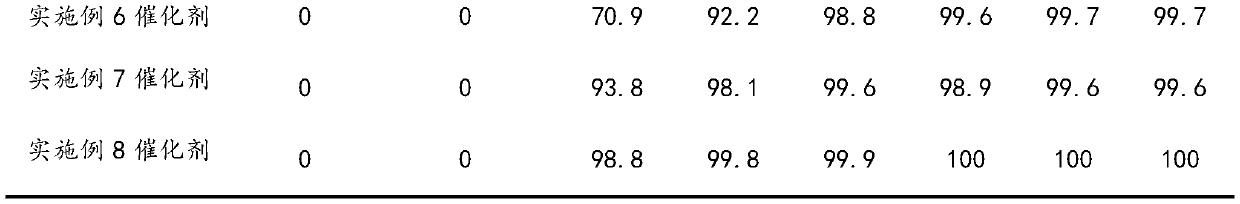

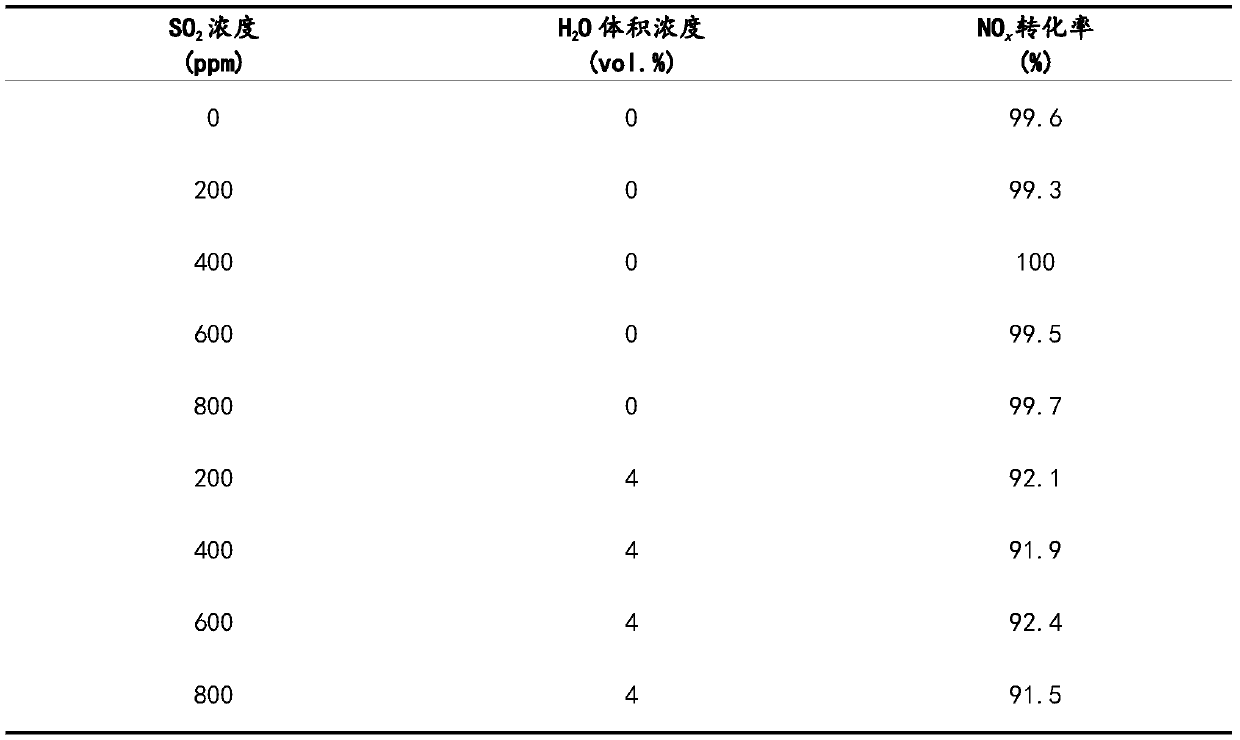

Examples

Embodiment 1

[0044] (1) Preparation of active components

[0045] The first step is to weigh 2g of the active component precursor V 2 o 5 Add 12ml of isobutanol (reducing agent) and 8ml of benzyl alcohol (solvent) to the Erlenmeyer flask, and after the Erlenmeyer flask is connected to a condensation reflux device, place it in a constant temperature magnetic stirring oil bath at 150°C to reflux for 3 hours In the second step, adding a certain amount of phosphoric acid with a concentration of 85% to the mixed solution in the first step, controlling the molar ratio of V and P to be 4:1, and continuing to reflux for 2h; the third step, conical The mixture in the bottle is suction filtered to realize solid-liquid separation; in the fourth step, the solid in the third step is roasted at 150° C. for 6 hours, and the active component vanadyl phosphate is obtained after cooling.

[0046] (2) Preparation of catalyst

[0047] The first step, weighing 0.2g active component vanadyl phosphate and 1.8...

Embodiment 2

[0049] (1) Preparation of active components

[0050] The first step is to weigh 2g of the active component precursor V 2 o 5 Add 12ml of isobutanol (reducing agent) and 8ml of benzyl alcohol (solvent) to the Erlenmeyer flask, and after the Erlenmeyer flask is connected to a condensation reflux device, place it in a constant temperature magnetic stirring oil bath at 150°C to reflux for 3 hours ; In the second step, adding a certain amount of phosphoric acid with a concentration of 85% to the mixed solution in the first step, controlling the molar ratio of V and P to be 5:1, and continuing to reflux for 2h; the third step, conical The mixture in the bottle is suction filtered to realize solid-liquid separation; in the fourth step, the solid in the third step is roasted at 150° C. for 6 hours, and the active component vanadyl phosphate is obtained after cooling.

[0051] (2) Preparation of catalyst

[0052] The first step, weighing 0.2g active component vanadyl phosphate and 1...

Embodiment 3

[0054] (1) Preparation of active components

[0055] The first step is to weigh 2g of the active component precursor V 2 o 5 Add 12ml of isobutanol (reducing agent) and 8ml of benzyl alcohol (solvent) to the Erlenmeyer flask, and after the Erlenmeyer flask is connected to a condensation reflux device, place it in a constant temperature magnetic stirring oil bath at 150°C to reflux for 3 hours ; In the second step, adding a certain amount of phosphoric acid with a concentration of 85% to the mixed solution in the first step, controlling the molar ratio of V and P to be 6:1, and continuing to reflux for 2h; the third step, conical The mixture in the bottle is suction filtered to realize solid-liquid separation; in the fourth step, the solid in the third step is roasted at 150° C. for 6 hours, and the active component vanadyl phosphate is obtained after cooling.

[0056] (2) Preparation of catalyst

[0057] The first step, weighing 0.2g active component vanadyl phosphate and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com