A kind of denitration catalyst, preparation method of denitration catalyst and denitration method

A denitration catalyst and manganese oxide technology are applied in the field of denitration catalysts and can solve the problems of improved catalyst activity, low optimum temperature for high activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

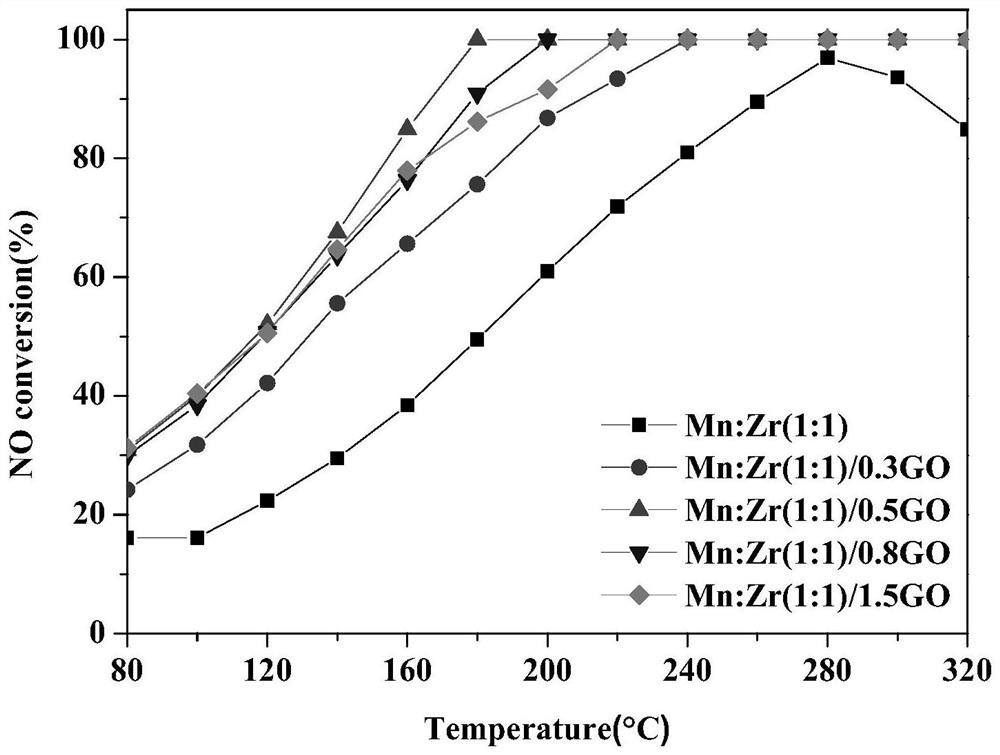

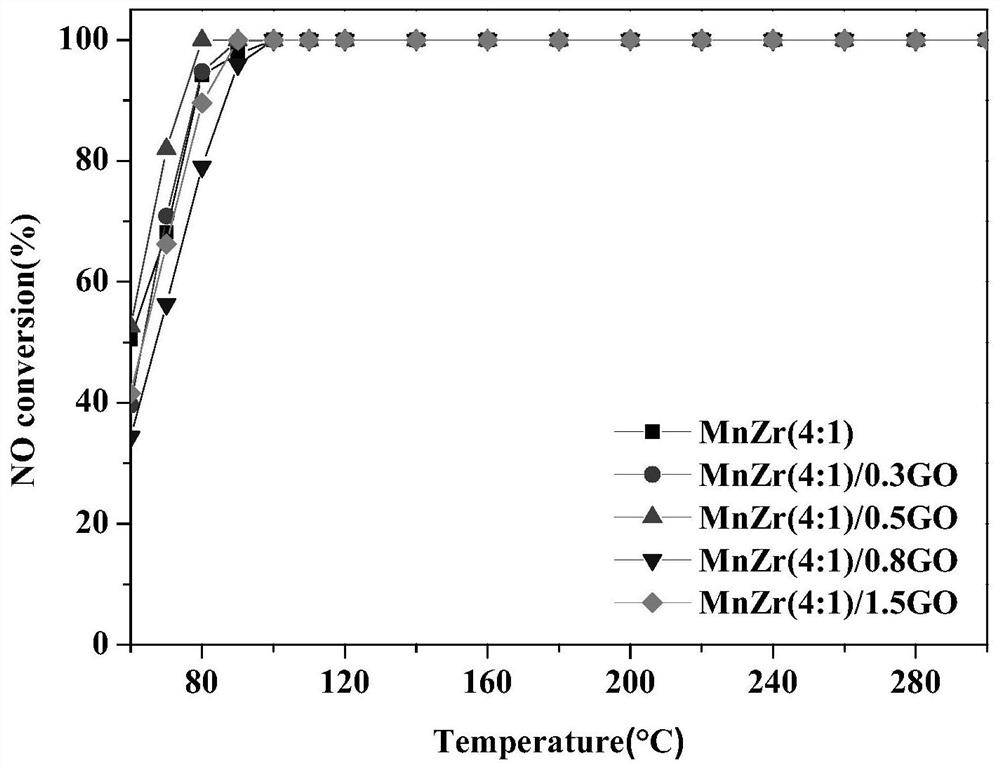

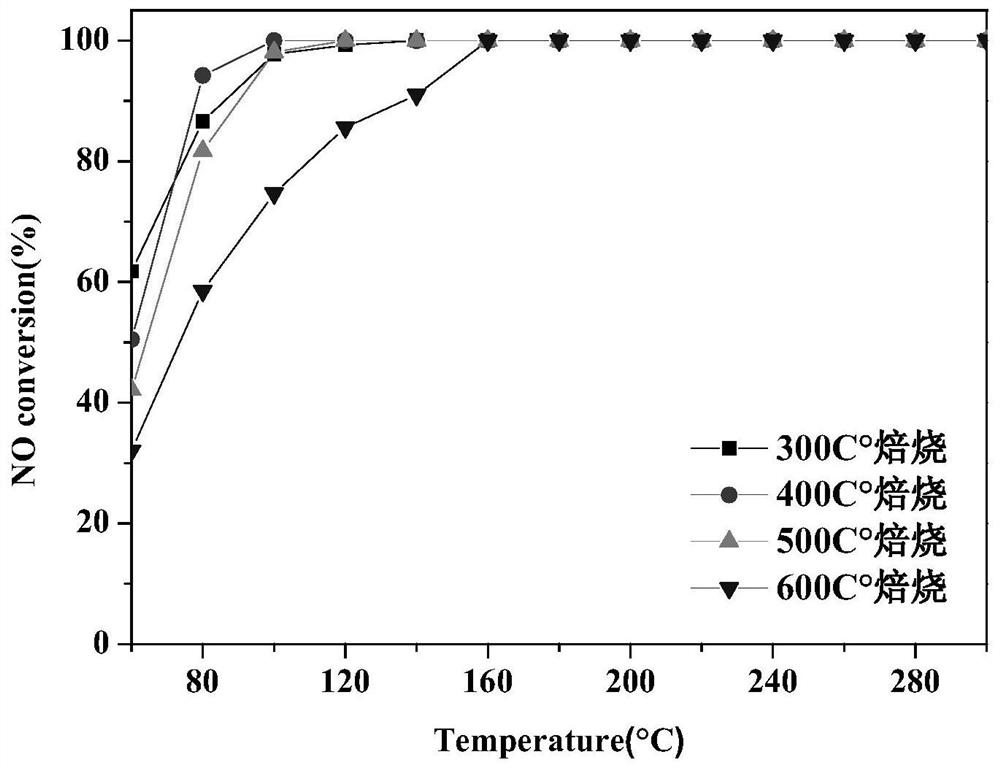

[0024] A method for preparing a denitration catalyst, comprising: drying a manganese source, a zirconium source, and graphene oxide after a hydrothermal reaction, and roasting at 300-600°C after drying, and manganese source and zirconium source corresponding to each other The molar ratio of manganese oxide and zirconium oxide is 3.5-4.5:1, and the ratio of the total mass of manganese oxide and zirconium oxide corresponding to manganese source and zirconium source to the mass of graphene oxide is 1000:2-7.

[0025] In the present invention, manganese source and zirconium source refer to the manganese oxide and zirconium oxide corresponding to them respectively: the amount of manganese oxide and zirconium oxide obtained after manganese source and zirconium source are respectively roasted.

[0026] Oxides can exist in a variety of unstable valence states in the catalyst, while facilitating redox reactions. Manganese-based catalysts use zirconia as a carrier. Zirconia is a p-type ...

Embodiment 1

[0046] This embodiment provides a denitration catalyst and a preparation method thereof.

[0047] A kind of preparation method of denitration catalyst:

[0048] Manganese acetate and zirconium nitrate are mixed in a molar ratio of 3.5:1 corresponding to manganese oxide and zirconium oxide (that is, manganese oxide and zirconium oxide generated respectively after roasting) to obtain a composite metal mixture, which is then dissolved in distilled water and compounded The metal mixture is dissolved in distilled water with the corresponding metal oxide at a ratio of 0.4mol:100ml to obtain a solution with manganese ions and zirconium ions. Then add graphene oxide to the metal ion solution, stir for about 30 minutes to make it mix uniformly to obtain the first mixed solution, the quality of the amount of graphene oxide added is the total mass of manganese oxide and zirconium oxide corresponding to manganese acetate and zirconium nitrate respectively The ratio is 2:1000.

[0049] A...

Embodiment 2

[0054] This embodiment provides a denitration catalyst and a preparation method thereof.

[0055] A kind of preparation method of denitration catalyst:

[0056] Mix manganese acetate and zirconium nitrate in a molar ratio of 4.5:1 corresponding to manganese oxide and zirconium oxide to obtain a composite metal mixture, and then dissolve it in distilled water. Dissolved in distilled water to obtain a solution with manganese and zirconium ions. Then add graphene oxide to the metal ion solution, stir for about 30 minutes to make it mix uniformly to obtain the first mixed solution, the quality of the amount of graphene oxide added is the total mass of manganese oxide and zirconium oxide corresponding to manganese acetate and zirconium nitrate respectively The ratio is 7:1000.

[0057] Add ammonia water to the first mixed solution, mix and stir for about 30 minutes, and adjust the pH to 10.6 to obtain the second mixed solution.

[0058] The second mixed solution was placed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com