Plate type wide temperature anti-sulfur SCR denitration catalyst and preparation method thereof

A denitrification catalyst, flat-plate technology, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of easy sulfur poisoning deactivation active temperature zone, etc., to reduce SO2 oxidation rate and optimize the preparation process , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

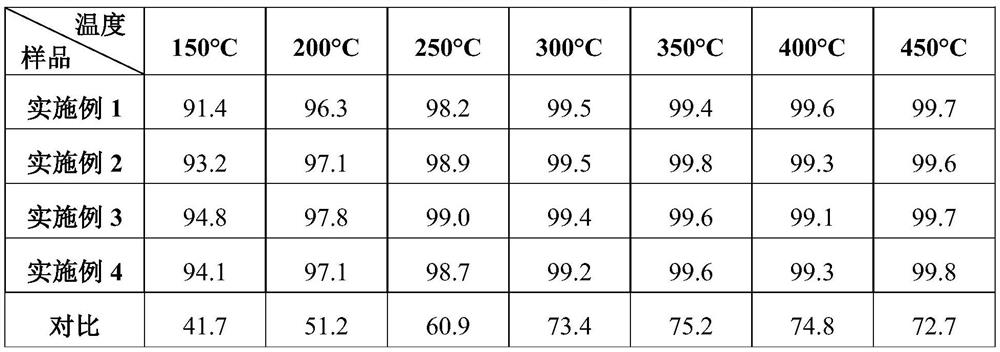

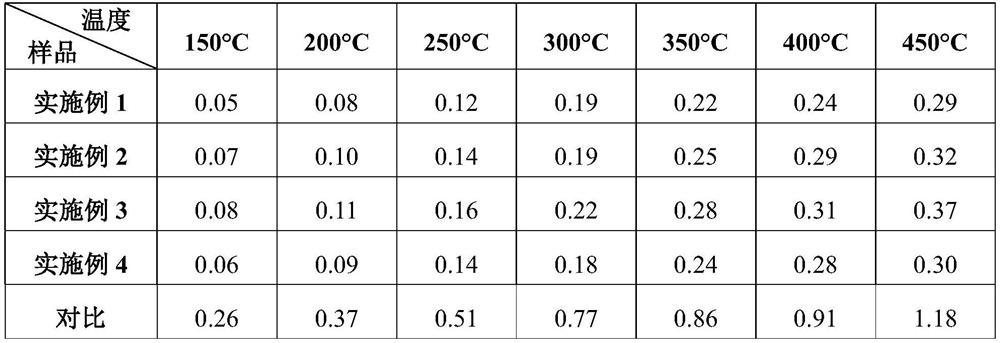

Examples

preparation example Construction

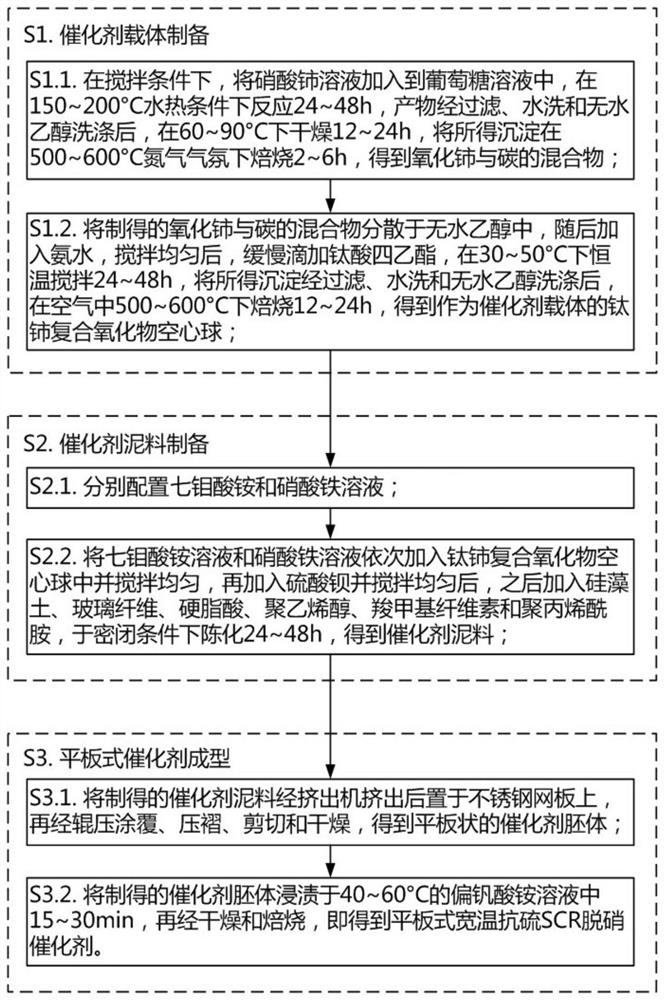

[0035] The preparation method of the flat plate type wide temperature anti-sulfur SCR denitration catalyst provided by the invention, such as figure 1 shown, including the following steps:

[0036] S1. Preparation of catalyst carrier:

[0037] S1.1. Under stirring conditions, add cerium nitrate solution to glucose solution, and react under hydrothermal conditions at 150-200 °C for 24-48 h. drying for 12-24 hours, and calcining the obtained precipitate in a nitrogen atmosphere at 500-600°C for 2-6 hours to obtain a mixture of cerium oxide and carbon;

[0038] S1.2. Disperse the prepared mixture of cerium oxide and carbon in absolute ethanol, then add ammonia water, stir evenly, slowly add tetraethyl titanate dropwise, and stir at a constant temperature of 30 to 50 ° C for 24 to 48 h, The obtained precipitate is filtered, washed with water and washed with absolute ethanol, and then calcined in air at 500-600° C. for 12-24 hours to obtain titanium-cerium composite oxide hollow ...

Embodiment 1

[0051] The preparation process of the flat plate type wide temperature anti-sulfur SCR denitration catalyst of the present embodiment is as follows:

[0052] (1) Under stirring conditions, 5.84L of 1mol / L cerium nitrate solution was added to 5L of 2mol / L glucose solution, and reacted for 48h under hydrothermal conditions at 150°C; the product was filtered, washed with water and washed with absolute ethanol , dried at 60 °C for 24 h, and then the precipitate was calcined at 500 °C under nitrogen atmosphere for 6 h to obtain a mixture of cerium oxide and carbon;

[0053] (2) Disperse the above mixture in 100L of absolute ethanol, then add 400mL of 25wt% ammonia; after stirring evenly, slowly add 994g of tetraethyl titanate dropwise, and stir at a constant temperature of 30°C for 48h; the obtained precipitate is filtered, washed with water and After washing with absolute ethanol, calcination in air at 500 °C for 24 h, the catalyst carrier titanium-cerium composite oxide hollow sp...

Embodiment 2

[0060] The preparation process of the flat plate type wide temperature anti-sulfur SCR denitration catalyst of the present embodiment is as follows:

[0061] (1) Under stirring conditions, 5.84L of 1mol / L cerium nitrate solution was added to 5L of 2mol / L glucose solution, and reacted under hydrothermal conditions at 200°C for 24h; After drying at 90°C for 12h, the precipitate was calcined under nitrogen atmosphere at 600°C for 2h to obtain a mixture of cerium oxide and carbon;

[0062] (2) Disperse the above mixture in 100L of absolute ethanol, and then add 376mL of 28wt% ammonia; after stirring evenly, slowly add 994g of tetraethyl titanate dropwise, and stir at a constant temperature of 50°C for 24h; the obtained precipitate is filtered, washed with water and After washing with anhydrous ethanol, calcination in air at 600℃ for 12h, the titanium-cerium composite oxide hollow spherical carrier can be obtained;

[0063] (3) 119 g of ammonium heptamolybdate and 151.5 g of ferri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com