Deformation-resistant anti-freezing sprayer nozzle component for sanitation cleaning trolley

A cleaning vehicle and anti-deformation technology, which is applied in the field of sanitation vehicles, can solve the problems of not taking heating protection measures, affecting the cleaning effect, and difficult to guarantee the water curtain, so as to prevent freezing or even cracking, improve cleaning efficiency, and eliminate welding errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

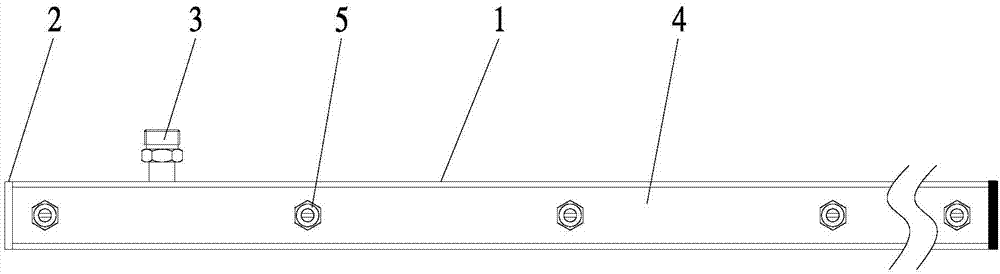

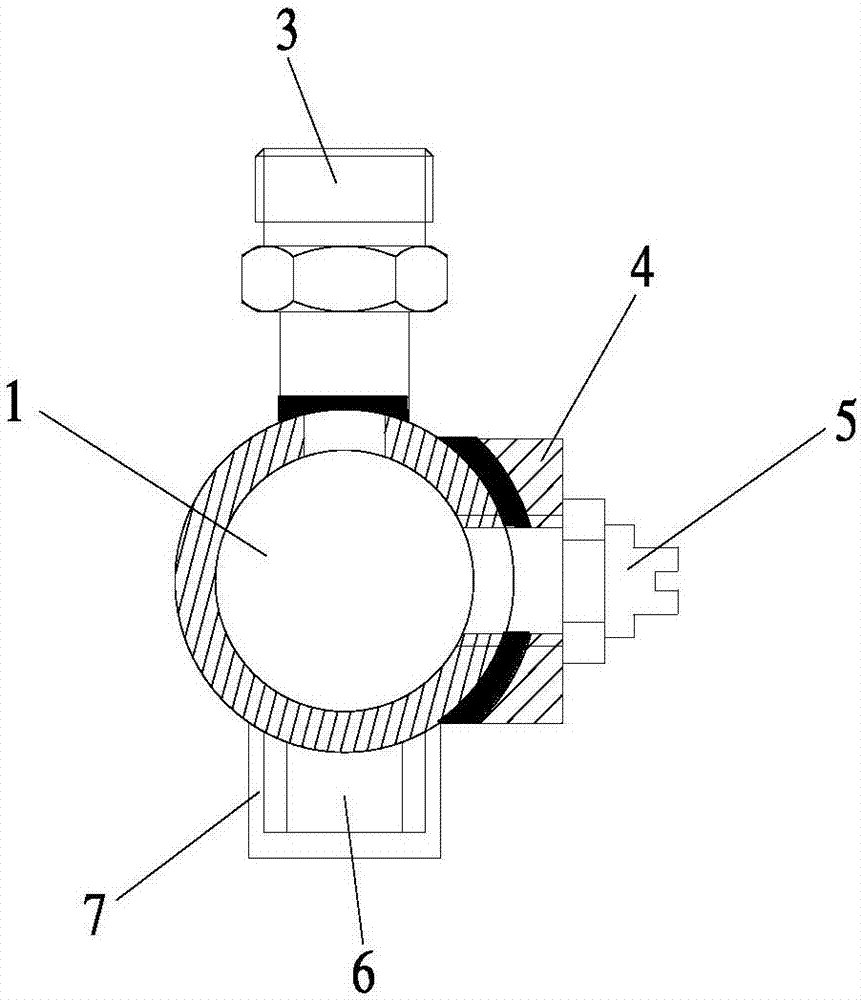

[0019] Such as figure 1 or figure 2 As shown, the present invention includes a nozzle 1, the two ends of the nozzle 1 are respectively fixed with plugs 2, and the side wall of the nozzle 1 is provided with a water inlet connector 3, the present invention also includes a connecting plate 4, the connecting plate 4 One side is welded to the outer wall of the nozzle 1 as a whole, and the other side of the connecting plate 4 is a flat surface. A plurality of threaded holes penetrated into the nozzle 1 are spaced along the axis of the nozzle 1 on the flat surface. In the embodiment, the threaded holes are arranged at equal intervals, the axis of each threaded hole is in the same plane, and each threaded hole is threaded with a nozzle 5; the outer wall of the nozzle 1 is provided with a heating device 6 extending along its axis direction, The heating device 6 heats the nozzle 1.

[0020] The present invention also includes a fixing plate 7 which is fixed on the outer wall of the nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com