Small circular hole cutting assisting device

An auxiliary device and round hole technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of few sides, affecting product quality, low repeat positioning accuracy, etc., and achieve the effect of precise shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

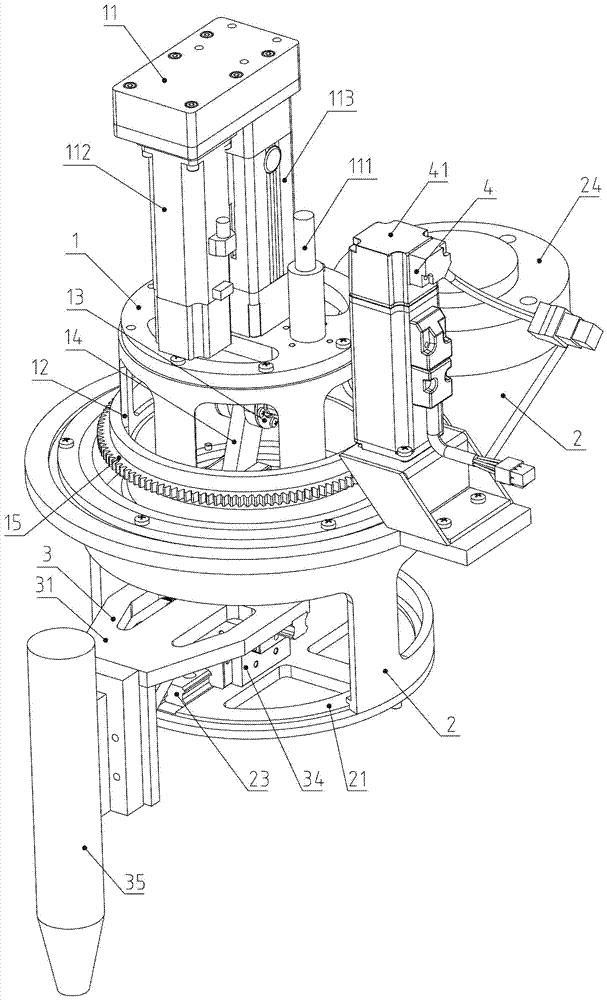

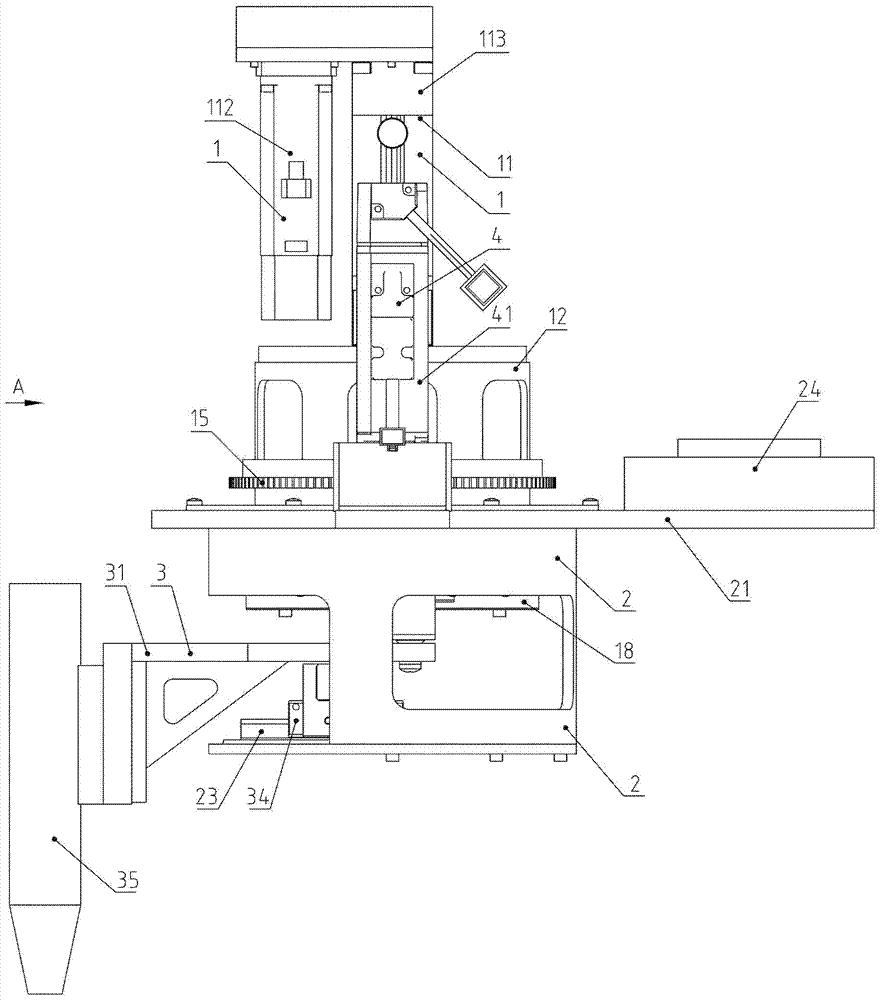

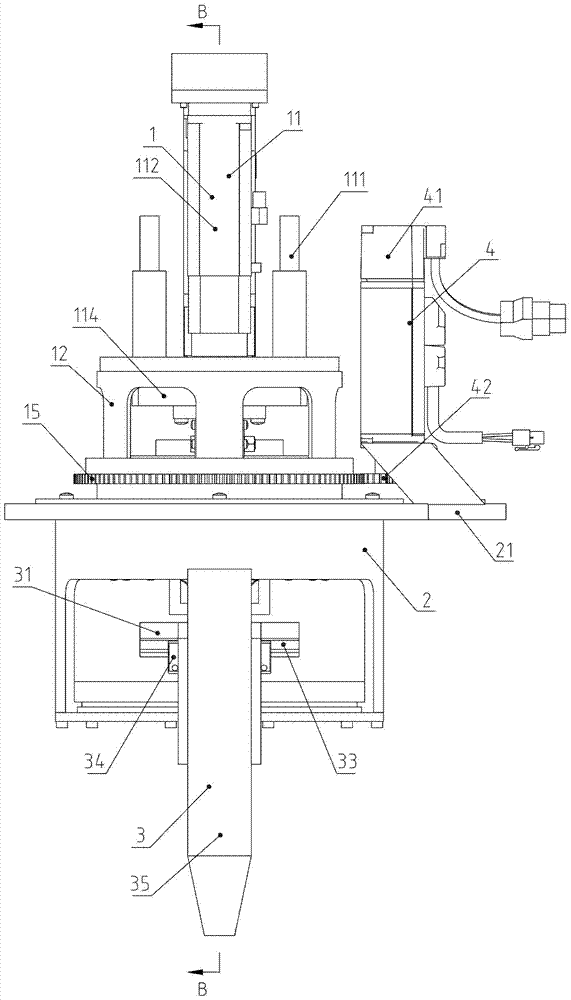

[0045] Example: see Figure 1 to Figure 10 .

[0046] An auxiliary device for cutting small round holes, comprising a rotary assembly 1, a bracket assembly 2, a laser assembly 3 and a rotary drive device 4;

[0047] The rotary assembly 1 includes a guiding electric cylinder 11, a rotating bracket 12, a connecting rod 14, a large gear 15, a linear slider 17 and a linear guide rail 18, and the guiding electric cylinder 11 includes a guide rod-guide sleeve combination 111, an electric cylinder servo motor 112 , the electric cylinder body 113 and the electric cylinder rod, the end of the electric cylinder rod is fixed with a cylinder rod end plate 114, the guide sleeve is fixedly connected with the electric cylinder body 113, the guide rod is fixedly connected with the cylinder rod end plate 114, the electric cylinder servo motor 112 and the electric cylinder The transmission mechanism in the cylinder block 113 is connected. When the electric cylinder servo motor 112 is energized...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap