Single-cylinder-driven rotary band-type brake mechanism

A transmission mechanism and single-cylinder technology, applied in the field of rotary brake mechanism, can solve the problems of high wear rate of the rotary brake nut, prolong the service life, reduce the cost of the machine, etc., and achieve the effect of low cost, long service life and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

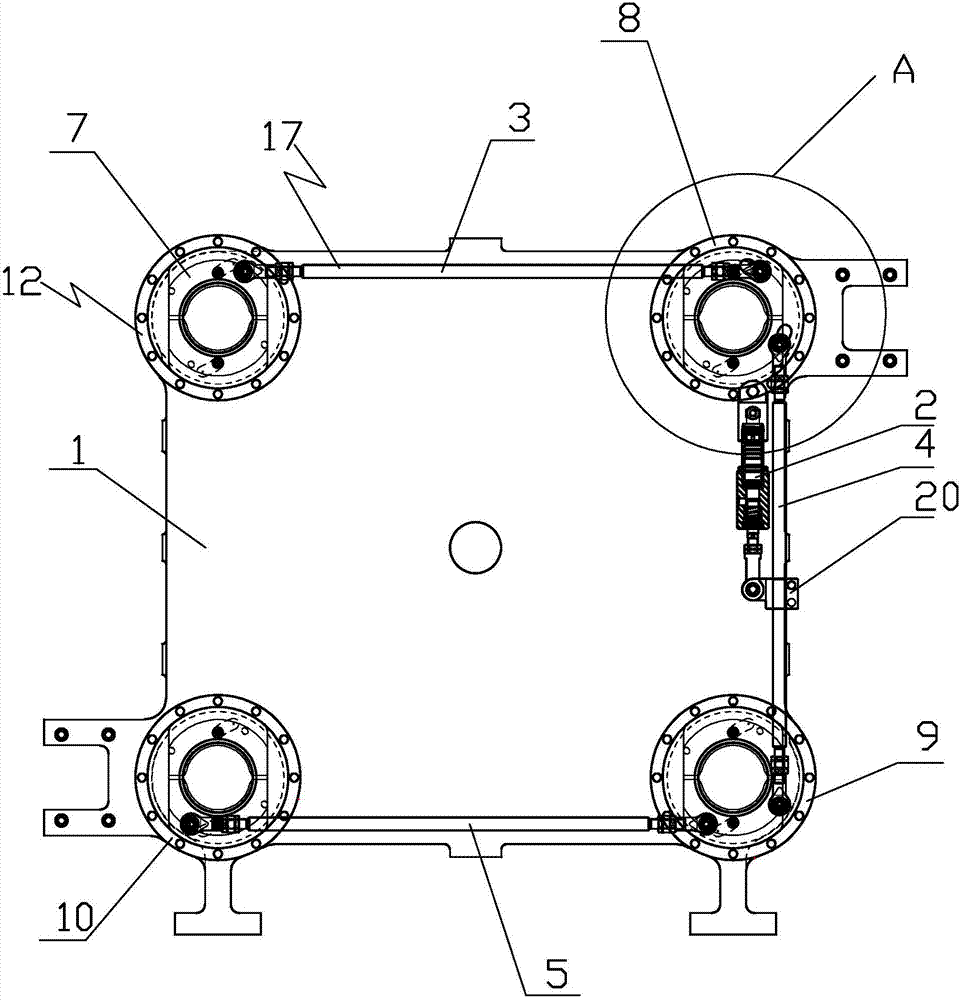

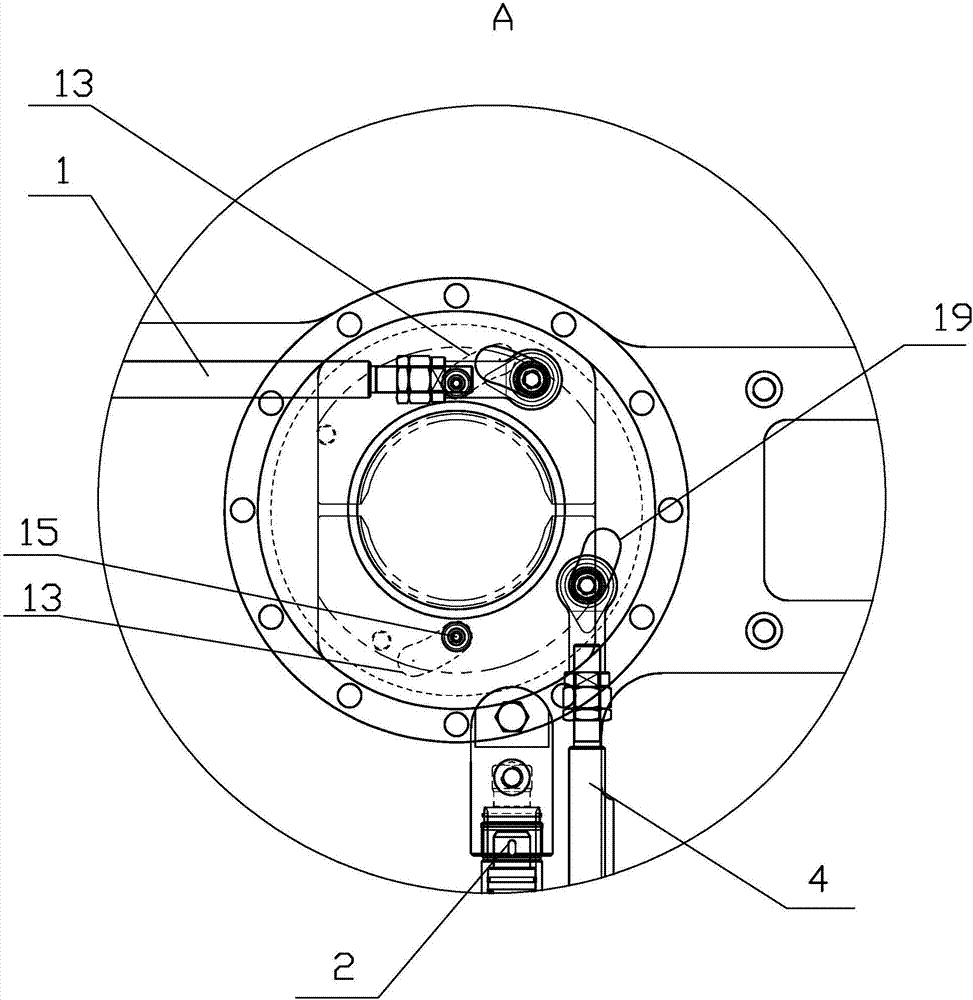

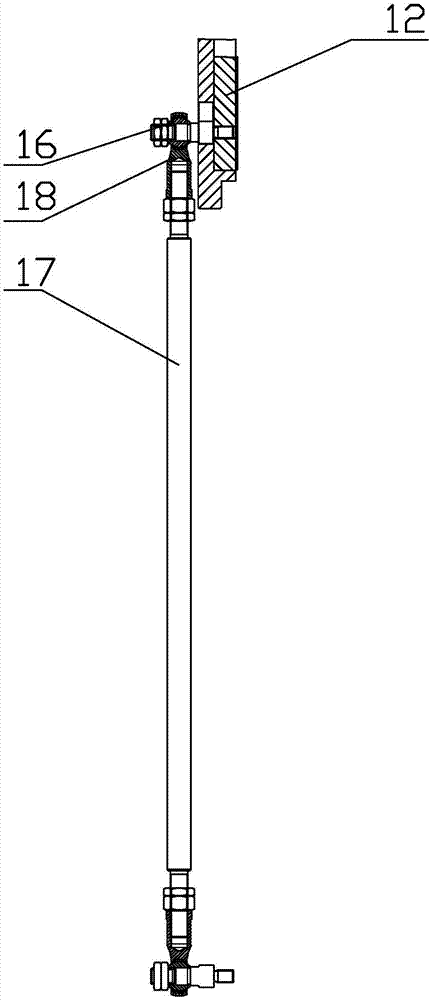

[0022] As shown in the figure, the present invention provides a rotary brake mechanism driven by a single cylinder, which includes a movable template 1, a brake cylinder 2, a connecting rod 17, an engagement nut 6 and a turntable 12, and the connecting rod 17 includes a first connecting rod. Rod 3, second connecting rod 4 and third connecting rod 5, said turntable 12 includes first turntable 7, second turntable 8, third turntable 9 and fourth turntable 10, said first turntable 7, second turntable The second turntable 8, the third turntable 9 and the fourth turntable 10 are arranged in sequence in a rectangular distribution, the first connecting rod 3 is located between the first turntable 7 and the second turntable 8, and the second link 4 is located between the first turntable 7 and the second turntable 8. Between the second turntable 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com