Low-viscosity mixed fracturing fluid, its application and oil and gas reservoir stimulation method

A technology for oil and gas reservoirs and fracturing fluids, applied in the field of reservoir reconstruction and oil and gas field reservoir reconstruction, can solve problems such as sand ingress, influence on fracture conductivity, damage, etc., and achieve improved seepage capacity and reservoir reconstruction. The effect of improving the effect and good diversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

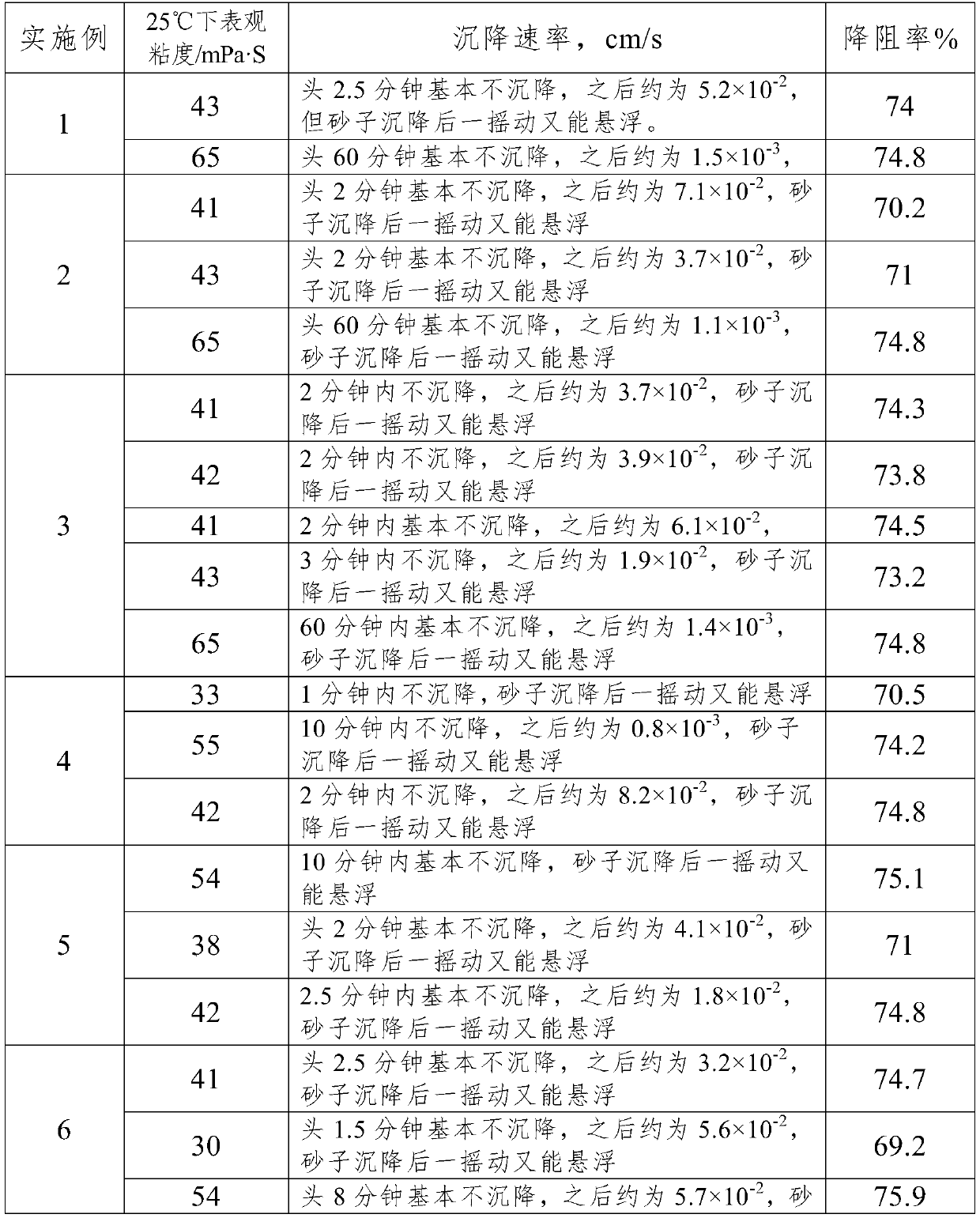

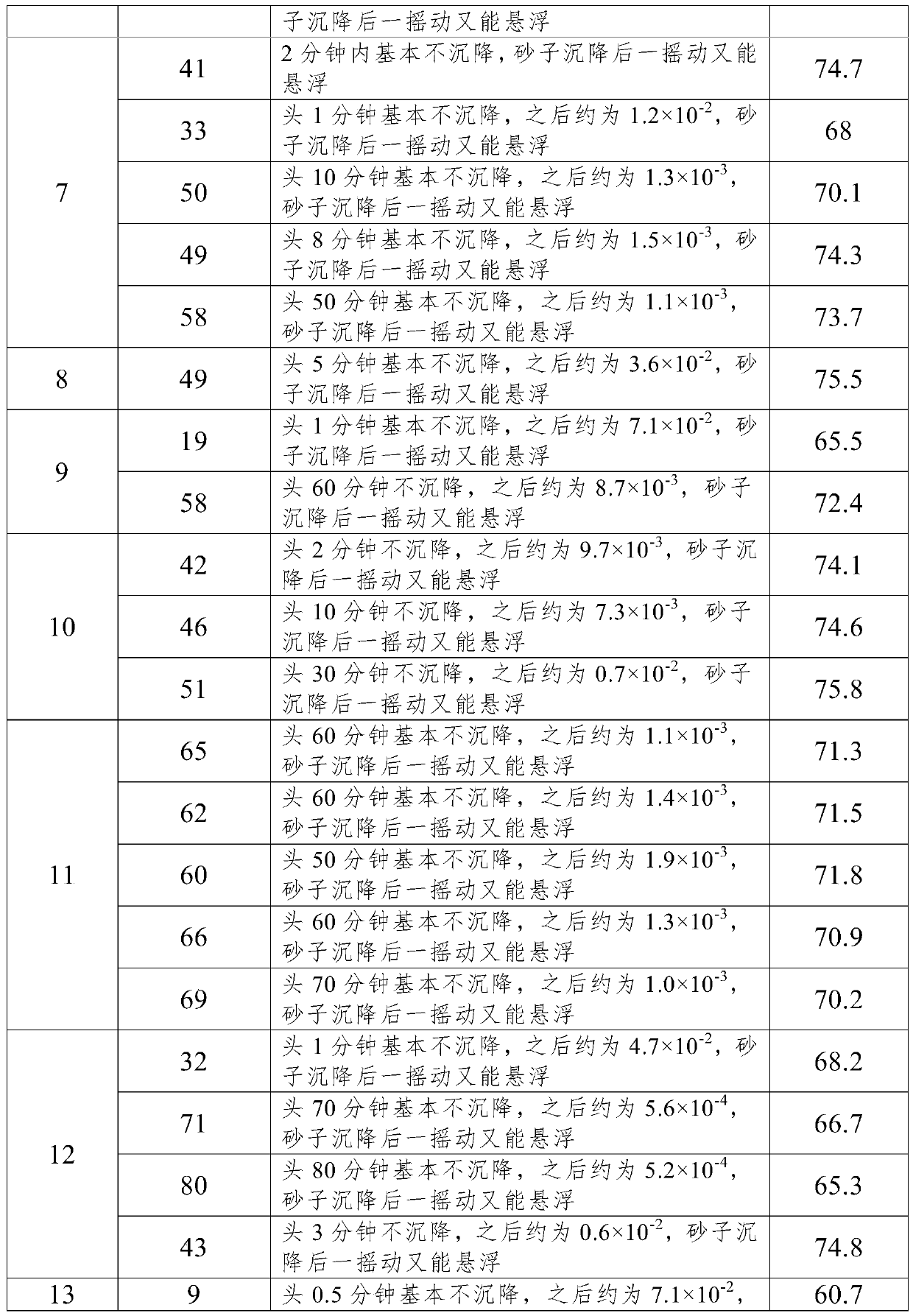

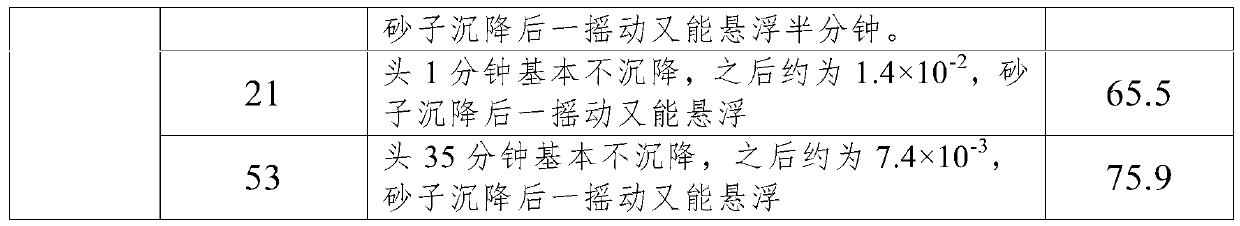

Examples

Embodiment Construction

[0051] The design idea of the present invention is mainly: the traditional fracturing fluid cannot contain acid, needs to be cross-linked, has high viscosity, and only has the function of sand fracturing, while the hybrid fracturing fluid developed by the present invention has no cross-linking and low viscosity After adding acid (or acid and active agent), it has several functions of sand fracturing and acidizing (and oil displacement). Sand fracturing and acidizing can be carried out at the same time, which improves the traditional fracturing process, especially, mixing The acid in the new fracturing fluid can also enter the narrow fractures that the sand carried by the traditional fracturing fluid can not enter, and turn the invalid fractures into effective fractures, greatly increasing the scope and effect of reservoir stimulation.

[0052] At the same time, the traditional fracturing fluid requires high viscosity and seeks to resist fluid loss during the fracturing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com