Room-temperature cured epoxy resin expansive soil modifier as well as preparation and application methods thereof

A technology of epoxy resin and soil modifier, applied in the field of geotechnical engineering, can solve the problems of reducing the swelling property of expansive soil, the difficulty of polymer, weakening the strengthening effect of polymer network, etc., to reduce the swelling ratio, and the preparation and construction methods are simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

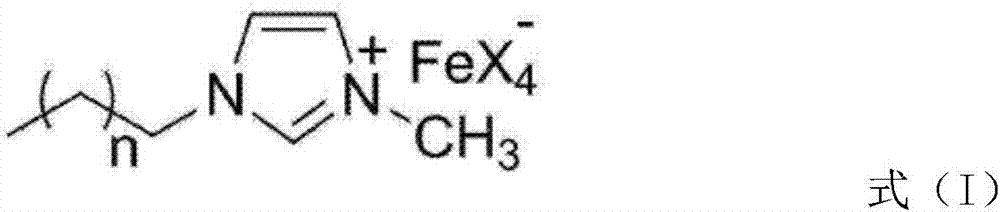

[0033] The synthesis method of magnetic ionic liquid is as described in Chinese invention patent application 201410461633.2. Concrete steps are as follows: (1) 1-hydroimidazole and iodine-containing alkyl compound are dissolved in solvent, then add potassium hydroxide to react, obtain the first mixed solution; (2) the first mixed solution is reacted with methyl iodide, obtaining a second product; and (3) reacting the second product with ferric chloride hexahydrate or ferric bromide hexahydrate to obtain a magnetic ionic liquid.

[0034] In an embodiment of the second aspect, step (2) may also include mixing one or more of water-generating heat-generating agents, defoamers, leveling agents, anti-settling agents, viscosity modifiers and diluents kind.

[0035] In a third aspect, the present invention provides a method for improving expansive soil using the epoxy resin expansive soil modifier as claimed in claim 1, the method may include the following steps: A. mixing epoxy resin,...

Embodiment 1-5

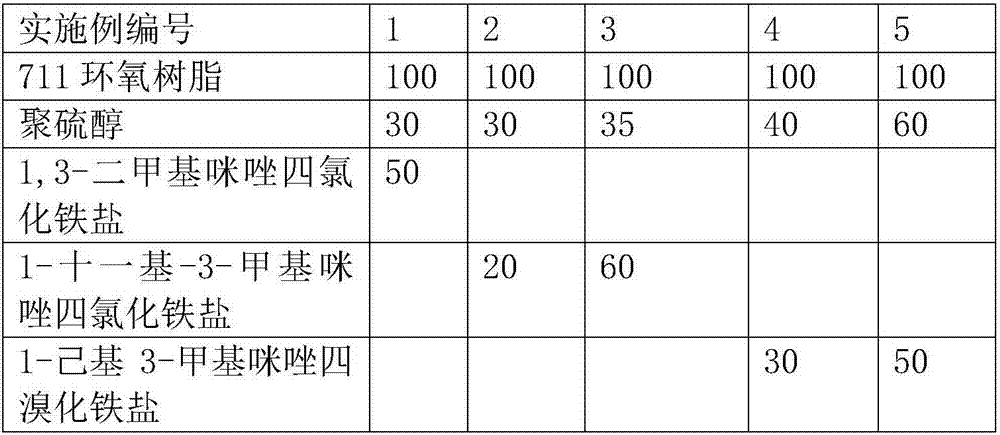

[0051] According to the formulation shown in Table 1 below, a liquid epoxy resin expansive soil modifier was prepared by thoroughly stirring the raw material components. Then, the resulting liquid epoxy resin expansive soil was sprayed onto the undisturbed expansive soil to improve the expansive soil. The specific construction technology and the test results of various indicators are shown in Table 2.

[0052] Table 1. The formula of the epoxy resin expansive soil modifier of embodiment 1-5 expressed in parts by weight

[0053]

[0054]

[0055] Table 2. Use the modifier of embodiment 1-5 to improve the condition of expansive soil and the performance index of expansive soil after improvement

[0056] Example number 1 2 3 4 5 Total amount of spraying (kg / m 2 )

[0057] From the experimental results in Table 2, it can be seen that after being improved by the epoxy resin expansive soil modifier of the present invention, the free expansion rate of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com