Assembly type overhead ground system for bathroom

A ground system and toilet technology, applied in the field of prefabricated toilet overhead ground system, can solve the problems of large quantity gap and huge investment in overall toilet production infrastructure, and achieve the effect of reducing production investment and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

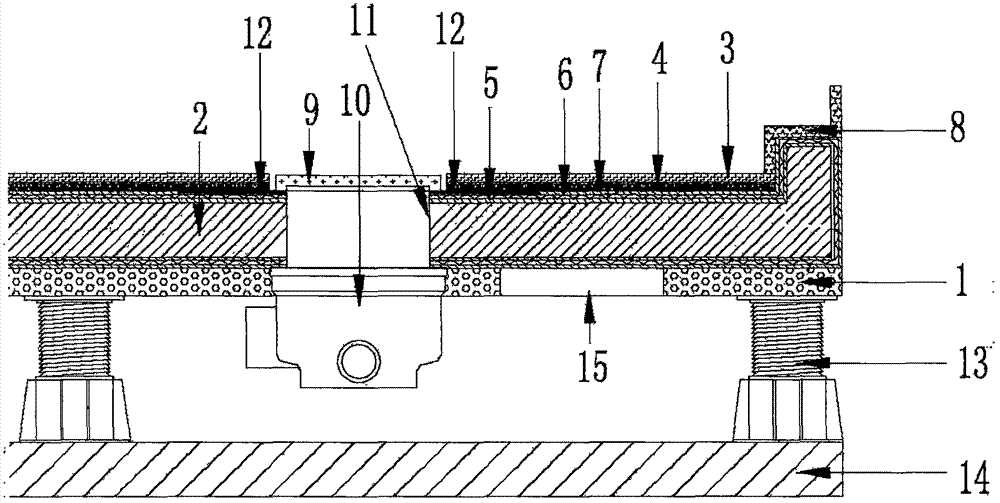

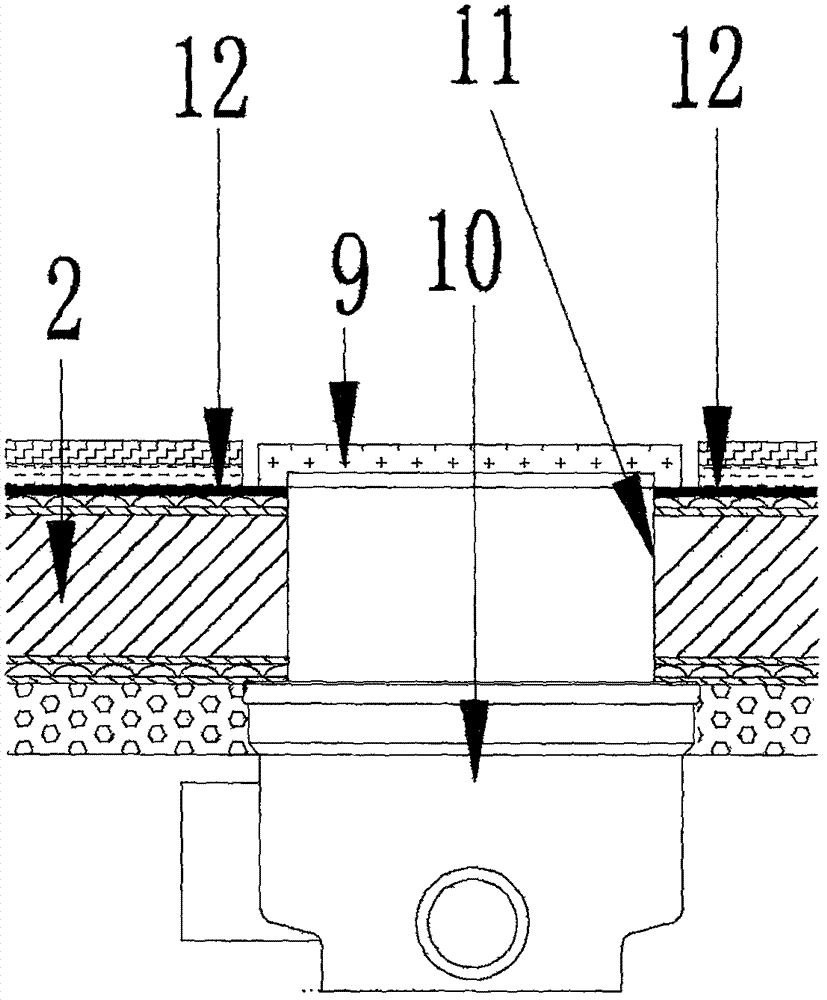

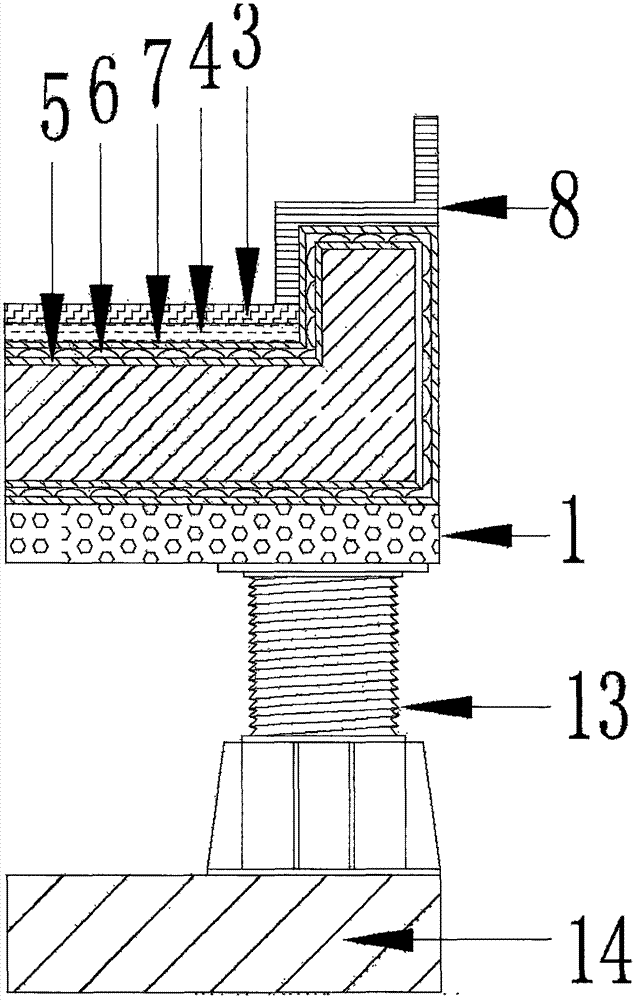

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Referring to the accompanying drawings, the prefabricated toilet overhead ground system includes a flat load-bearing structure (1), a tiled waterproof chassis (2) on the flat load-bearing structure (1), and a decorative ground layer laid on the waterproof chassis (2) (3), the decorative surface layer bonding layer (4) sandwiched between the waterproof chassis (2) and the decorative surface layer (3), the bottom of the flat load-bearing structure (1) is supported on the concrete by height-adjustable resin bolts (13) on the ground (14). In the present invention, the flat load-bearing structure (1) is a cement fiber board with a thickness of 25 mm, and the waterproof chassis (2) is wrapped with polymer cement mortar and alkali-free glass fiber cloth on the surface of an XPS extruded board with a thickness of 50 mm, and the decorative ground layer (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com