Transmission wire icing thickness prediction method and device

A technology for icing thickness and transmission wire, which is applied in the field of prediction method and device for icing thickness of transmission wire, which can solve problems such as uneven icing, frequent tripping, and dependence on the quality and quantity of icing observation data, and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

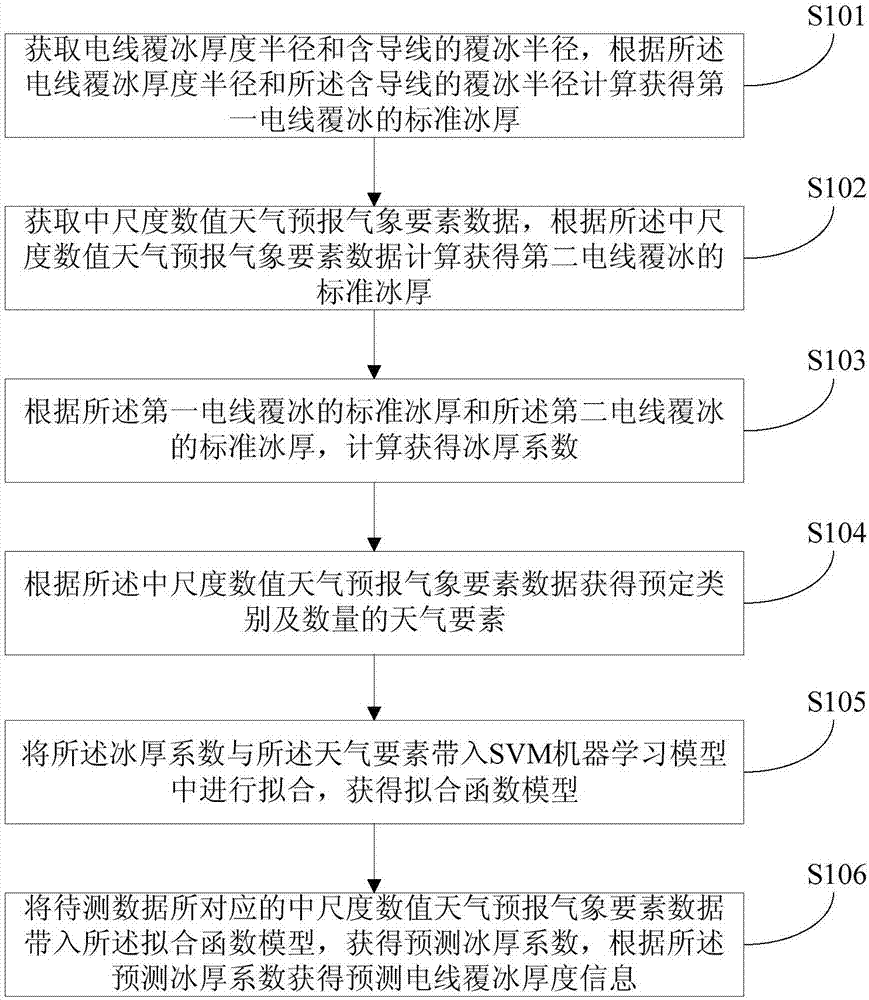

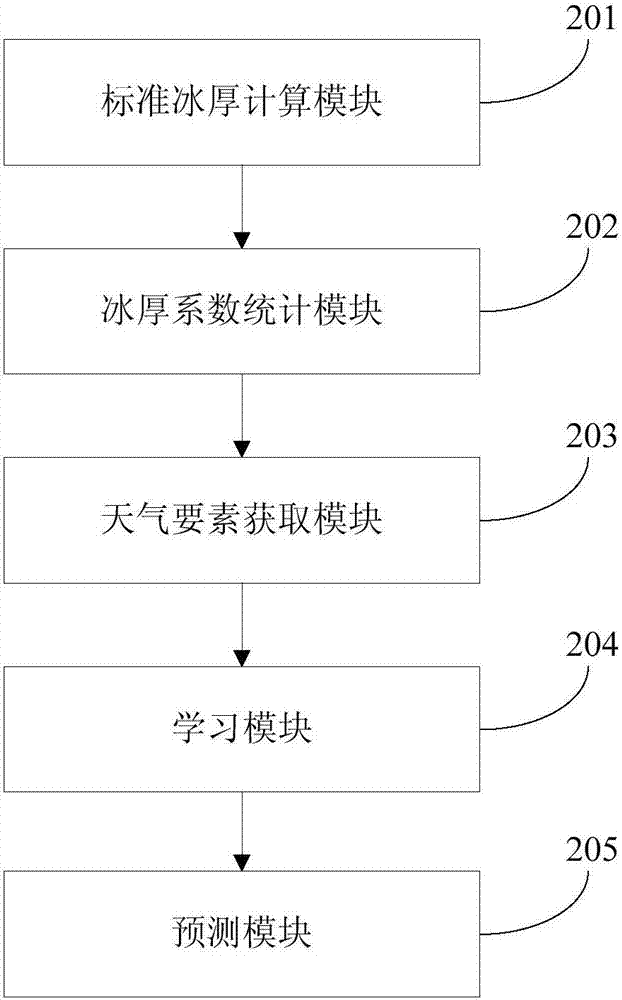

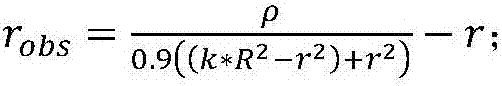

[0028]The method for predicting the icing thickness of transmission wires provided by the present invention mainly consists of the following processes in principle: first, obtain the data of the icing thickness of the electric wire, and convert the data of the icing thickness of the electric wire into standard ice thickness data; then, use the mesoscale numerical weather forecasting model Simulate the storm-scale weather, obtain the forecast results of the mesoscale numerical weather prediction model, and substitute the forecast results into the empirical model of ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com