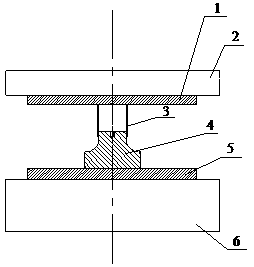

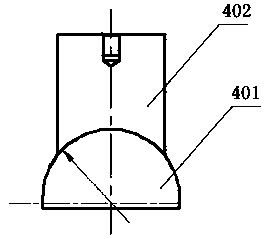

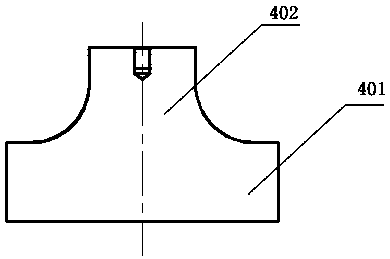

Tooling for precise forming of metal saddle pipe fittings and method for processing saddles

A technology of precision molding and saddle, which is applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc. It can solve the problems of high labor intensity for operators and low molding efficiency, so as to improve product quality, reduce molding time, and reduce replacement. The effect of modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention has been applied to the DN250 standard copper-nickel equal-diameter saddle, the weight of a single piece of blank is reduced from 13.79KG to the current 11.5KG, the material is reduced by 2.29KG, and the total molding time of a single saddle is reduced from 2.5 hours before for 1 hour.

Embodiment 2

[0029] The present invention has been applied to the DN300 standard copper-nickel equal-diameter saddle, the weight of a single piece of blank is reduced from 15.89KG to the current 12.5KG, the material is reduced by 3.39KG, and the total molding time of a single saddle is reduced from 2.5 hours before for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com