Automatic automobile oxygen sensor assembly pressing system and operation method thereof

An automobile oxygen sensor and oxygen sensor technology, which is applied in the field of press-fitting system, can solve the problems of low degree of automation and inability to meet the demand, and achieve the effects of improving work efficiency, shortening press-fitting and detection time, and reducing assembly time

Active Publication Date: 2017-08-29

HANGZHOU TAISHANG MACHINERY CO LTD

View PDF15 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The degree of automation is relatively low and cannot meet the needs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Login to View More

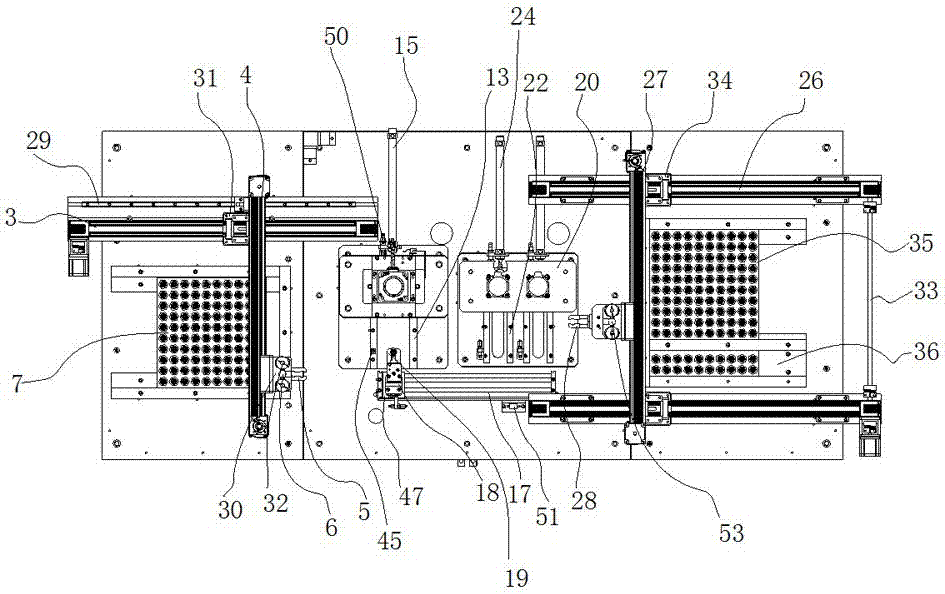

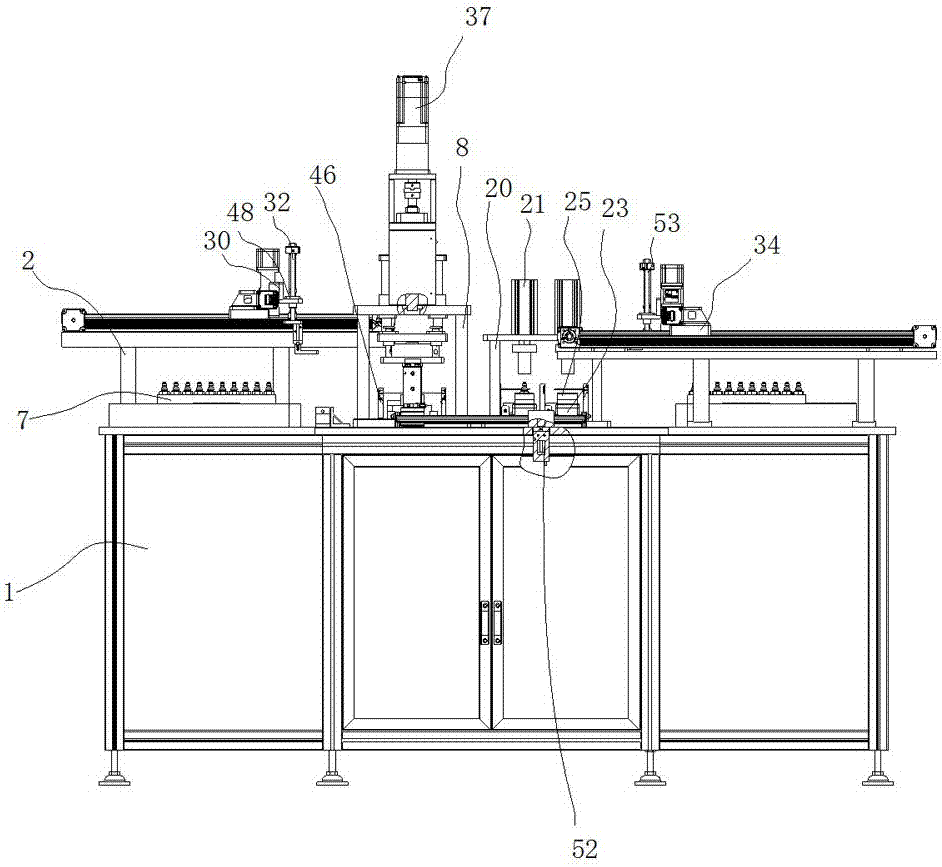

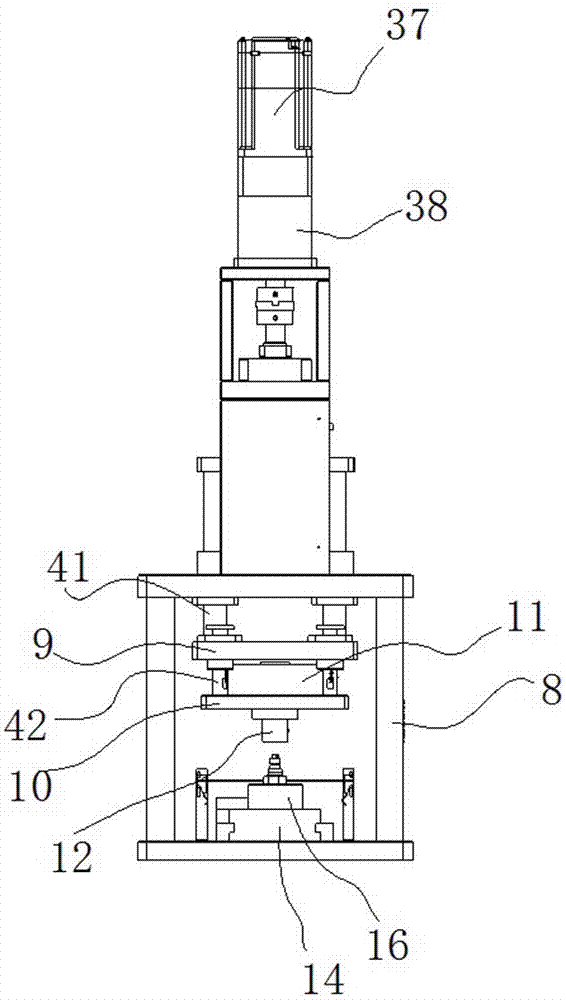

Abstract

The invention relates to a pressing system, and particularly relates to an automatic automobile oxygen sensor assembly pressing system and an operation method thereof. The automatic automobile oxygen sensor assembly pressing system comprises a rack, wherein a feeding station assembly, a pressing station assembly, a sliding station assembly, a moving station assembly, a detection station assembly and a discharging station assembly are arranged on the upper part of the rack, the feeding station assembly and the sliding station assembly are correspondingly distributed, the sliding station assembly and the pressing station assembly are matched and connected in a sliding mode, the moving station assembly is distributed respectively corresponding to the sliding station assembly and the detection station assembly, and the discharging station assembly and the detection station assembly are correspondingly distributed. The automatic automobile oxygen sensor assembly pressing system and the operation method thereof have the advantages of compact structure and high degree of automation, and the operating precision is increased.

Description

An automatic automotive oxygen sensor component press-fitting system and its operating method technical field The invention relates to a press-fitting system, in particular to an automatic automotive oxygen sensor component press-fitting system and an operating method thereof. Background technique Automobile oxygen sensor is a key sensing component in EFI engine control system. It is a key part to control automobile exhaust emissions, reduce automobile environmental pollution, and improve the fuel combustion quality of automobile engines. The oxygen sensor uses ceramic sensitive elements to measure the oxygen potential in various heating furnaces or exhaust pipes, and calculates the corresponding oxygen concentration based on the principle of chemical balance to achieve monitoring and control of the furnace. With the development and growth of the automobile industry, the annual Production is constantly rising. The oxygen sensor is a key sensing component in the automoti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P19/02G01M3/26

CPCG01M3/26B23P19/001B23P19/02Y02T10/40

Inventor 徐正方张秋阁

Owner HANGZHOU TAISHANG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com