Preparation method for 5N high-purity aluminum nitrate

An aluminum nitrate, high-purity technology, applied in directions such as aluminum nitrate, can solve problems such as time-consuming, slow reaction, mercury pollution discharge, etc., and achieve the effects of avoiding mercury pollution, short production cycle, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

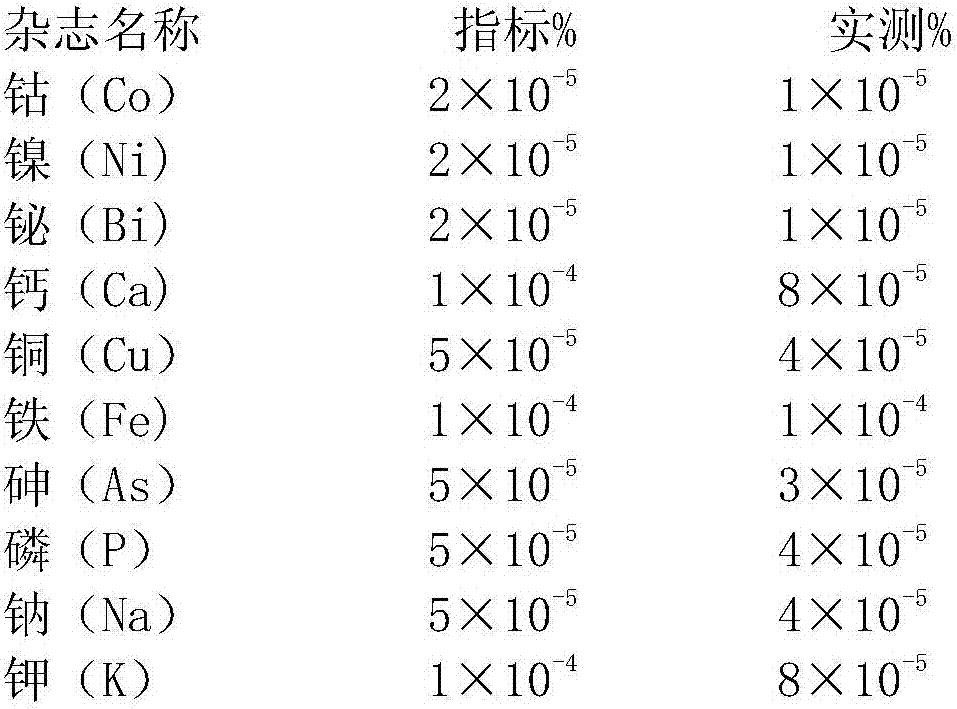

Image

Examples

preparation example Construction

[0023] A kind of preparation method of 5N high-purity aluminum nitrate (99.999%), its step is:

[0024] ⑴Metal aluminum pretreatment: clean the high-purity aluminum sheet with a thickness of about 0.2 mm with acetone, then rinse with pure water, then soak in high-purity 10% nitric acid at room temperature for 15 minutes, and then rinse with pure water for later use;

[0025] (2) Decomposition: Put the pretreated high-purity metal aluminum flakes into a 5000 ml three-neck glass flask, add 2500 ml of high-purity nitric acid with a concentration of 30% to 35% (weight percentage), install a reflux condenser, and pass it into Cooling water, the flask is heated to reflux with a temperature-adjusting electric heating mantle, and the temperature of the reaction solution is maintained at 100-120°C until no brownish-yellow gas is produced. Next, use a G4 glass filter to suction filter, and the filtrate is transferred to a 5000 ml glass beaker for subsequent use;

[0026] (3) Concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com