Wastewater treatment system with multiple crystallizer units and wastewater treatment method based thereon

A wastewater treatment system and crystallizer technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., to slow down pipe plugging, reduce operating costs, reduce the generation of large salt and wall hanging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

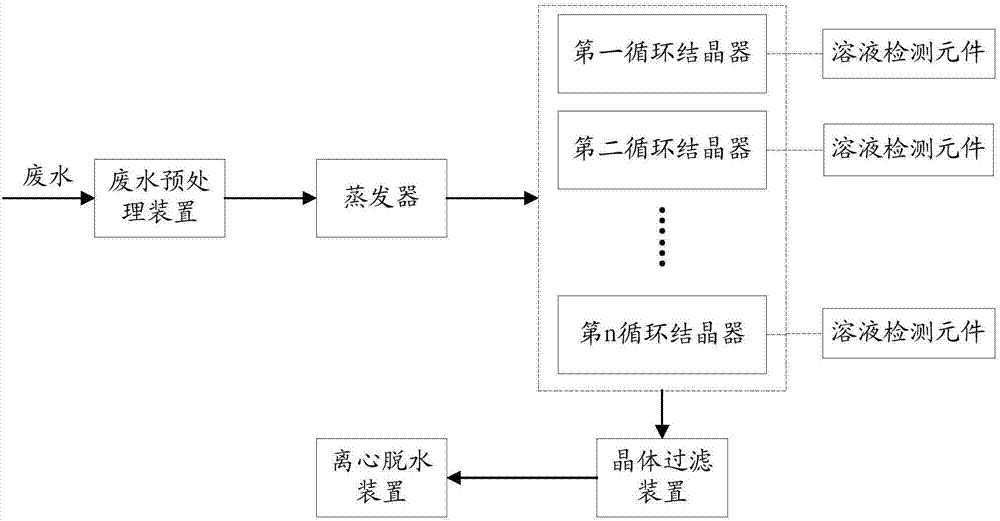

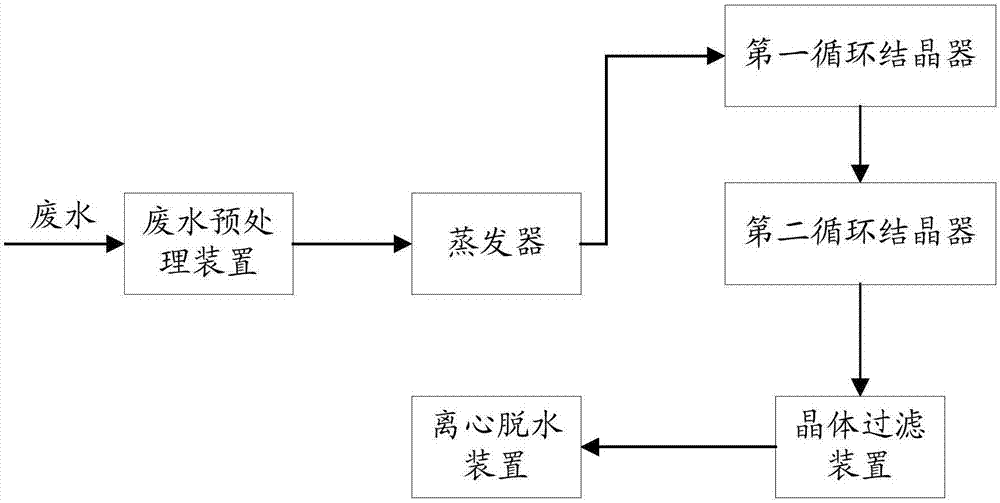

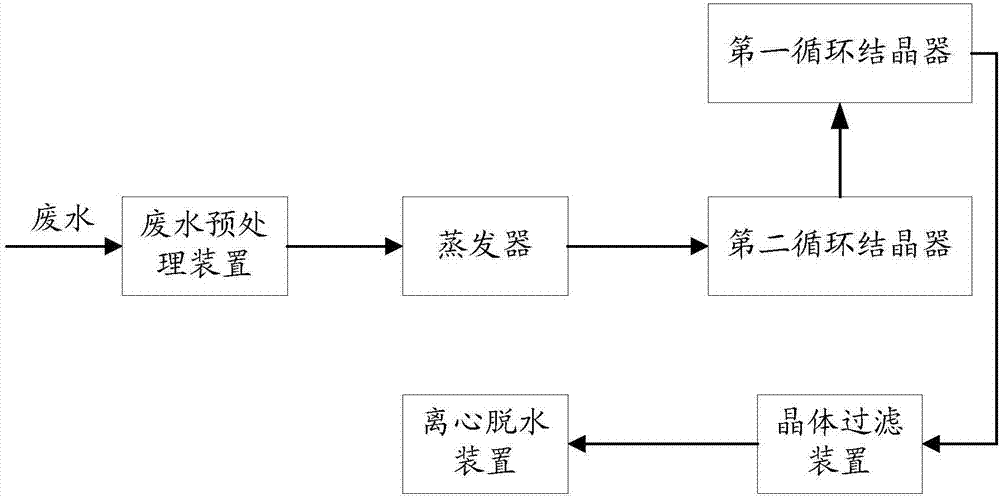

[0028] Reference figure 1 , The wastewater treatment system with multiple sets of crystallizers described in this embodiment includes: a wastewater pretreatment device, an evaporator, a circulating crystallizer group, a crystal filtration device, and a dehydration device; the wastewater pretreatment device, the The evaporator, the circulating crystallizer group, the crystal filtering device, and the dehydrating device are connected in sequence; the circulating crystallizer group includes a main inlet, a main outlet, and a plurality of circulating crystallizers; the main inlets are respectively Connected to the evaporator and the inlet of each circulating crystallizer, and the main outlet is respectively connected to the crystal filtering device and the outlet of each circulating crystallizer; any two circulating crystallizers are connected by connecting valves; each cycle A solution detection element is arranged in the crystallizer; the system also includes a controller, which i...

Embodiment 2

[0034] In this embodiment, the wastewater treatment method based on the wastewater treatment system with multiple crystallizers as described in embodiment 1, the method includes:

[0035] S1, start the wastewater treatment system, and the wastewater to be treated passes through the wastewater pretreatment device and the evaporator in turn, and enters the circulating crystallizer group for this round of crystallization cycle;

[0036] S2, each circulating crystallizer in the circulating crystallizer group is sequentially numbered in the order from first to last through which the wastewater to be treated flows;

[0037] Set the circulating crystallizer that the wastewater to be treated currently passes through first as the first circulating crystallizer, and set the circulating crystallizer that the wastewater to be treated currently passes through last as the nth circulating crystallizer, where n represents the circulating crystallizer The total number of circulating crystallizers in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com