High-definition, neutral-color and low-emissivity coated glass and preparation method

A low-emissivity coating and low-emissivity glass technology, which is applied in sputtering, ion implantation, vacuum evaporation, etc., can solve the problems of heavy color tone, greenishness, and affect the decorative effect of the film surface, so as to reduce the production Cost, pure color, fresh and beautiful color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

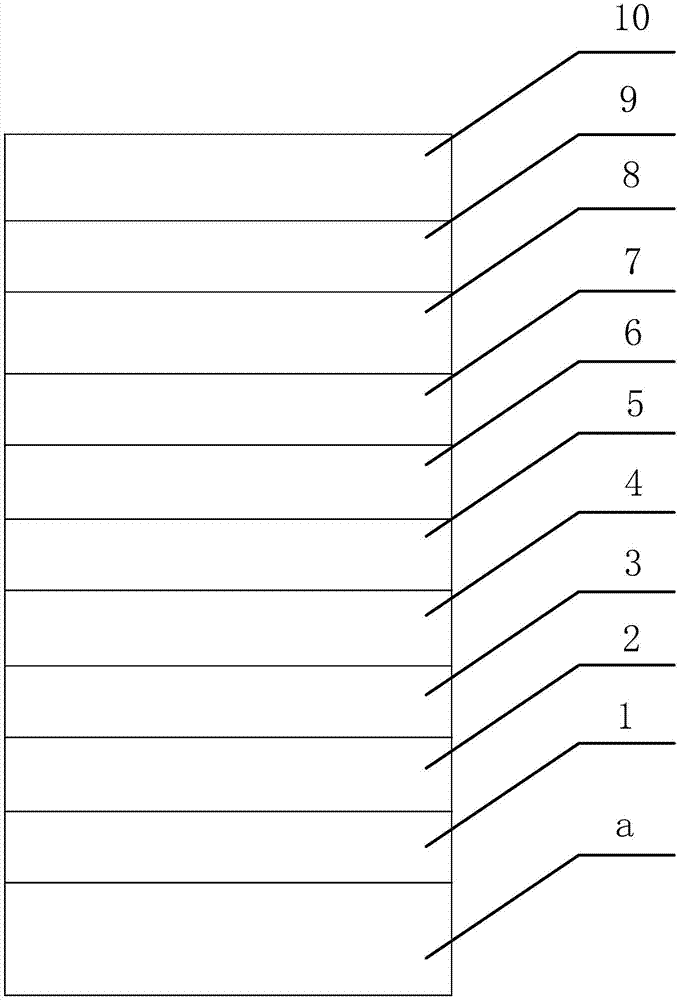

[0040] Such as figure 1 As shown, the high-definition neutral color low-emissivity coated glass includes a glass substrate layer a and a coating layer located on the side of the glass substrate layer a, and the coating layer is sequentially compounded with ten film layers outward from the glass substrate layer a, The first layer 1 is ZnSnO / ZnO or a mixed layer of both, the second layer 2 is Ag layer, the third layer 3Cu layer, the fourth layer 4 is NiCr layer, and the fifth layer 5 is Fe 2 o 3 layer, the sixth layer 6 is ZnSnO / ZnO or a mixed layer of both, the seventh layer 7 is Ag layer, the eighth layer 8 is NiCr layer, and the ninth layer 9 is Fe 2 o 3 layer, and the tenth layer 10 is a SiNx layer.

[0041] Wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap