Base substance replacement type ecological filter dam

A filter dam and matrix technology, which is applied in the field of matrix replacement ecological filter dam, achieves the effect of good use effect, convenient use, and solving the effect of ecological environment protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

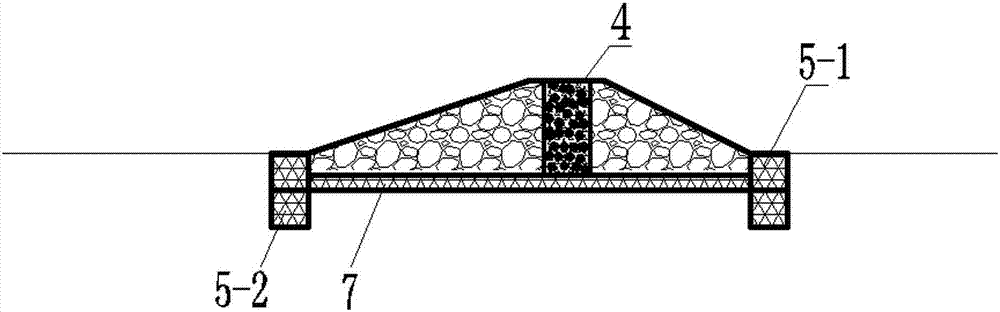

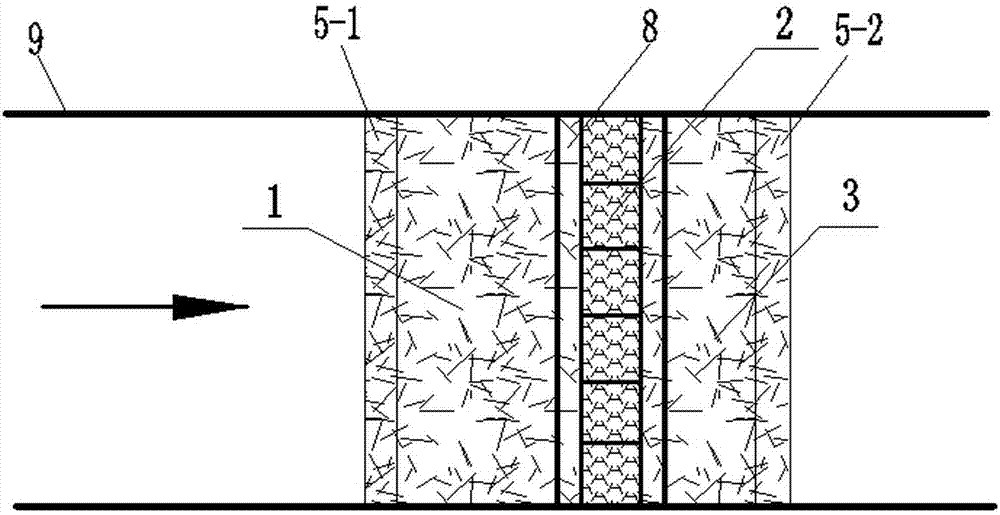

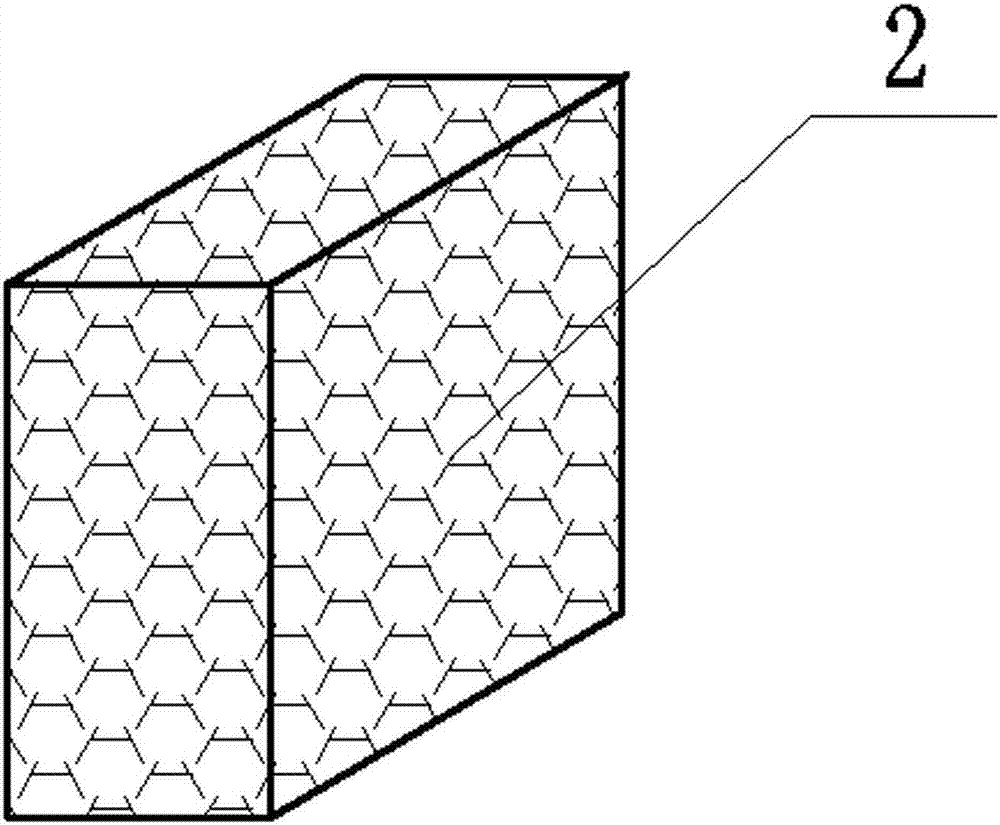

[0012] like Figure 1-4 As shown, the present invention includes an upstream filter dam body 1 and a downstream filter dam body 3; a filler space 8 is formed between the upstream filter dam body 1 and the downstream filter dam body 3, and a metal filler frame 2 is housed in the filler space 8, and a metal filler frame 2 is installed There are three-dimensional elastic porous packing balls 4, and the packing balls 4 are filled with matrix packing 6. The upstream filter dam body 1 and the downstream filter dam body 3 are both surface layers made of stones, and the surface layer below the surface layer is made of gravel, zeolite and iron slag. The inner layer made of the mixture of equal weight has the first filter dam base pile 5-1, the second filter dam base pile 5-2 on both sides of the bottom of the upstream filter dam body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com