Integrated type microchannel heat exchanger

A micro-channel heat exchanger, heat exchanger technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as increased flow resistance, medium leakage, system failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

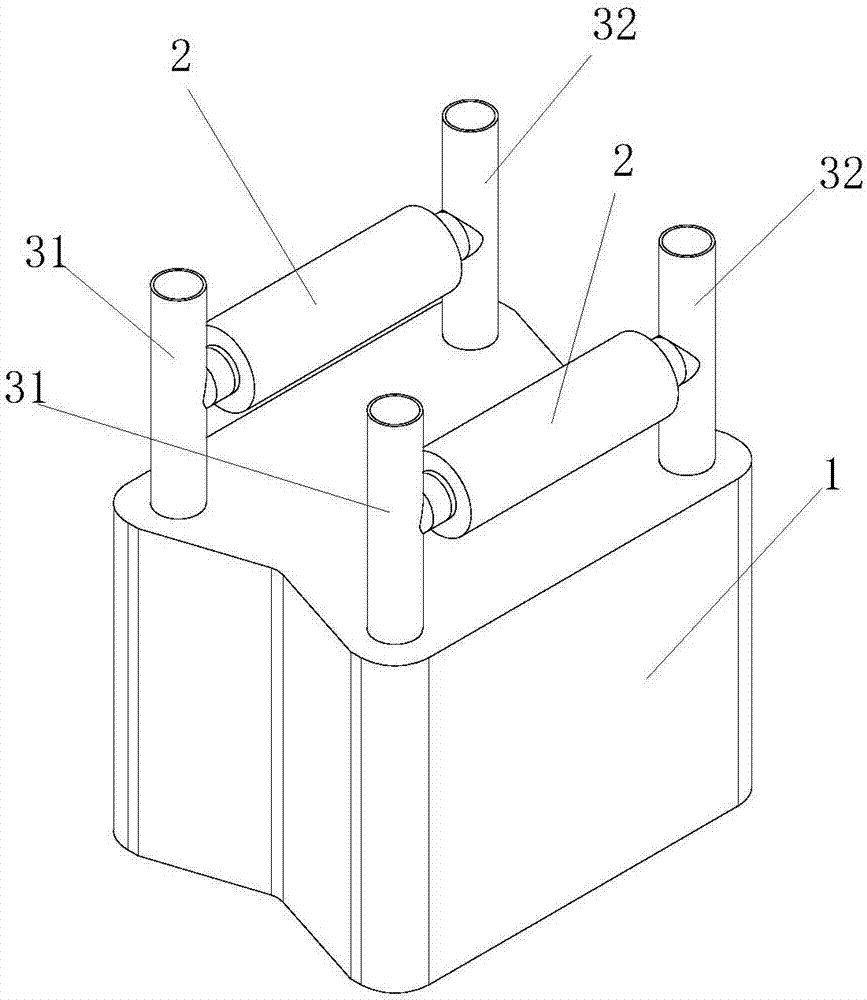

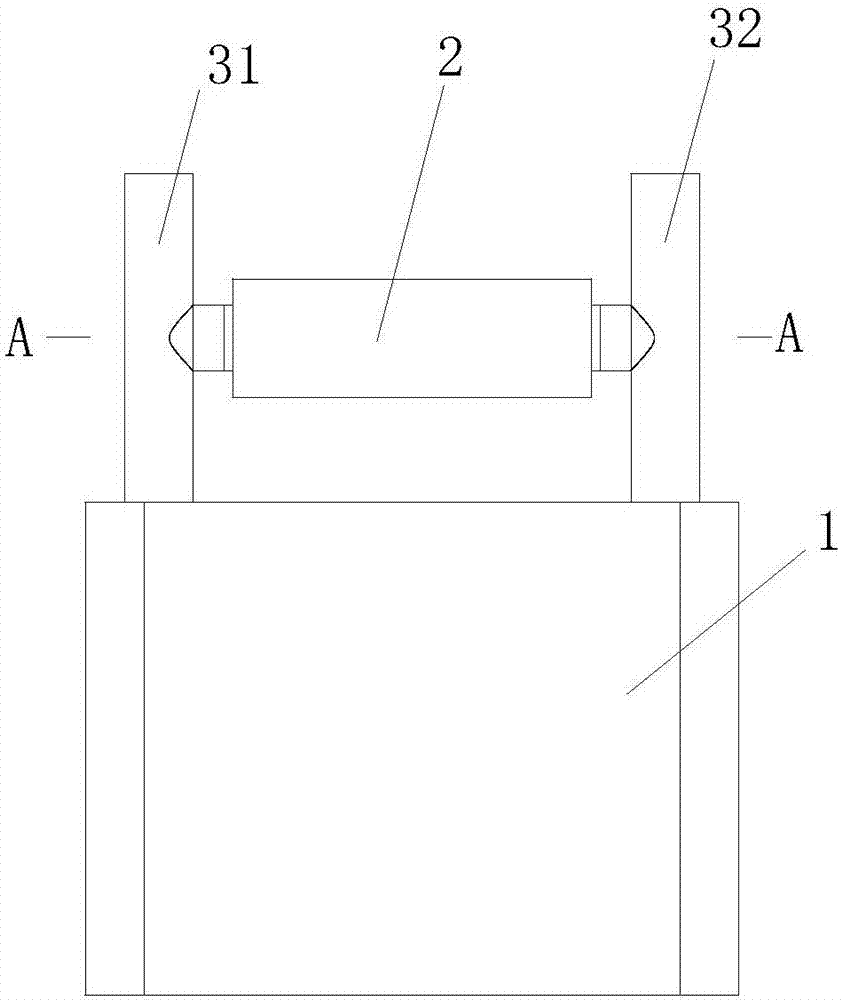

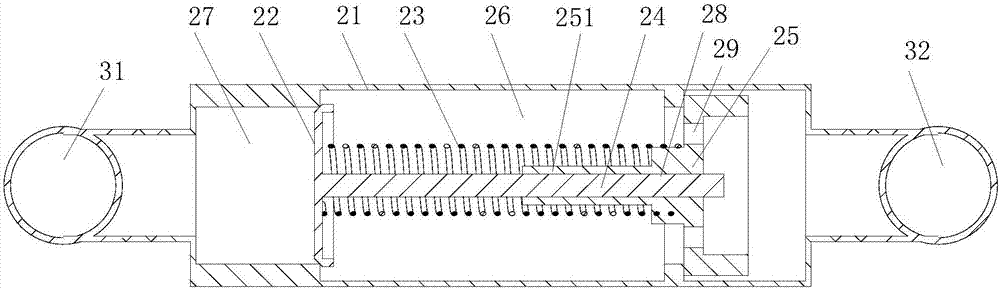

[0015] Example 1: Reference Figure 1-3 . An integrated micro-channel heat exchanger, comprising a heat exchanger core 1, a current collecting circuit, and a pressure sensing device 2. The heat exchanger core 1 is connected with at least a group of current collecting circuits, and the current collecting circuit includes a first The header 31 and the second header 32; the first header 31 and the second header 32 are connected with a pressure sensing device 2 in communication, and the pressure sensing device 2 includes a valve body 21, a plug 22, The spring 23, the support rod 24, the valve seat 25, the valve body 21 is provided with a cavity 26, the left side of the cavity 26 is provided with a valve port 27, the right side is connected with a valve seat 25, and the valve port 27 is provided in the cavity 26 There is a plug 22, the center of the valve seat 25 is provided with a guide hole 28, the support rod 24 penetrates the guide hole 28, and its left end is connected with th...

Embodiment 2

[0017] Example 2: Reference body 1-3. On the basis of Example 1. The heat exchanger core 1 is provided with two or more current collecting circuits, and the first collecting pipe 31 and the second collecting pipe 32 of each collecting circuit are connected with a pressure sensing device 2 in communication.

Embodiment 3

[0018] Example 3: Reference figure 1 , image 3 , Figure 4 . On the basis of Embodiment 1, a temperature sensing package 30 is provided on one end of the valve seat 25 near the spring 23, and the temperature sensing package 30 is wrapped around the outside of the spring 23 on the corresponding side. The temperature sensing package 30 is encapsulated with a temperature sensing medium. The temperature sensing medium melts and expands at high temperature, solidifies and contracts at low temperature, and then squeezes the spring, thereby controlling the elastic force of the spring and the expansion and contraction force of the medium inside the temperature sensing package The degree to which the plug is opened or closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com