Detection alarm system for automatically checking deformation of inner wall of pipeline

An automatic inspection and alarm system technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of inability to detect the deformation of the inner wall of the pipeline, unreliable detection results, etc., and achieve reliable detection results, low cost, structure and away from simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

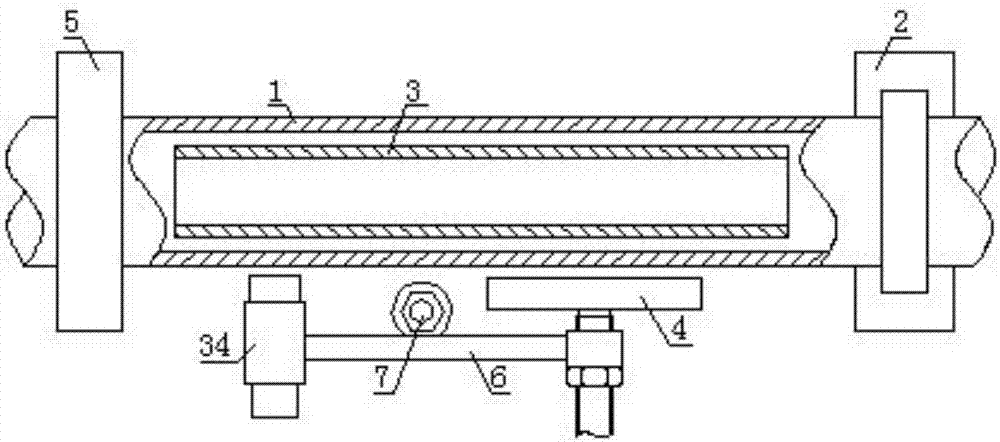

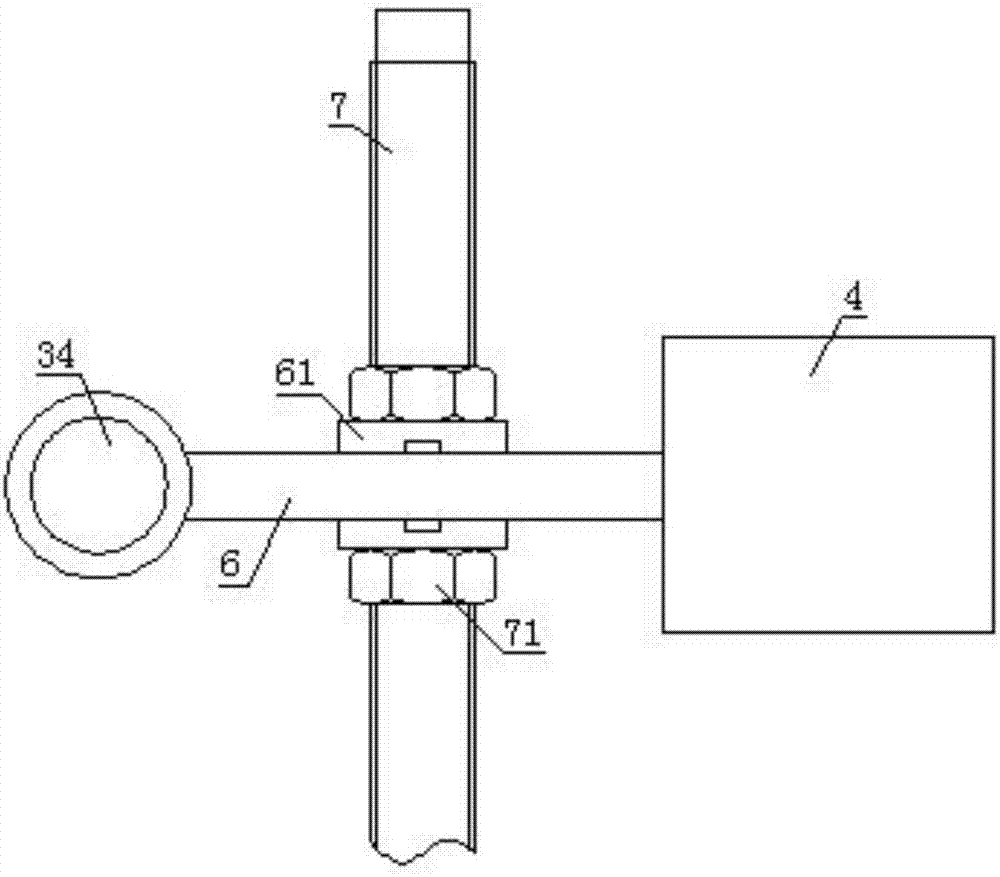

[0031] Such as figure 1 As shown, the present invention includes a pipeline 1, which is connected with a conveying device 2 for conveying the pipeline 1; it is characterized in that, a metal piece 2 is placed inside the pipeline 1, and an electromagnetic induction system 3 and an electromagnetic induction system 3 are respectively arranged outside the pipeline 1. The electromagnetic induction system 3 includes an alarm 31 for the magnet 4 that holds the metal piece 2 .

[0032] The magnet 4 of the present invention can attract the metal piece 2 in the pipeline 1, and the metal piece 2 will not move during the transportation of the pipeline 1. When the inner wall of the pipeline 1 is deformed, the protrusion at the deformed place will take away the metal part 2, so that the on-off of the electromagnetic induction system 3 changes, and the on-off of the alarm 31 changes, reminding the staff to take corresponding measures. The present invention detects the deformation of the pip...

Embodiment 2

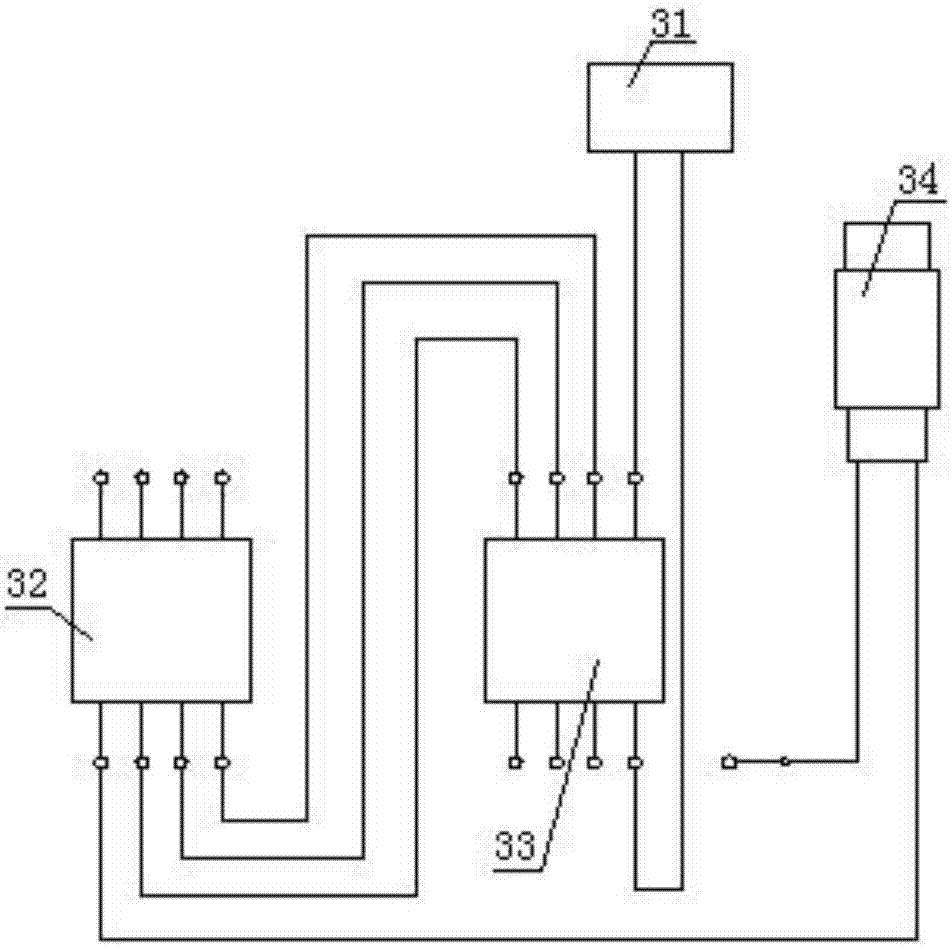

[0034] Such as figure 2 As shown, on the basis of Embodiment 1, the electromagnetic induction system 3 also includes a main electric switch 32, the main electric switch 32 is electrically connected to an AC contactor 33, and the AC contactor 33 is electrically connected to a metal inductor 34, and the metal induction The alarm 34 is set close to the area where the metal piece 2 is arranged on the pipeline 1, and the alarm 31 is electrically connected to the AC contactor 33.

[0035] When the inner wall of the pipeline 1 is deformed, the metal piece 2 is taken away by the pipeline 1, and the connection contact of the AC contactor 33 changes. If the alarm 31 is connected to the normally closed contact of the AC contactor 33, the alarm 31 changes from disconnection to connection, and the alarm 31 sends out an alarm. If the alarm 31 is connected to the normally open contact of the AC contactor 33, the alarm 31 changes from a circuit to an open circuit, and the alarm 31 stops sen...

Embodiment 3

[0037] On the basis of Embodiment 1 or Embodiment 2, a cutting machine 5 is installed on the running path of the pipeline 1 .

[0038] When the worker learns through the information of the alarm 31 that the pipeline 1 passing through the magnet 4 has deformation, start the cutting machine 5 to cut off the deformed pipe section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com