Directly-pressing fluid measuring method and measuring device

A technology of metering device and metering method, which is applied in the direction of fixed measuring room, etc., can solve the problems of poor metering accuracy, large hose damage, inconvenient cleaning, etc., and achieve the effect of no repeat error, small damage and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

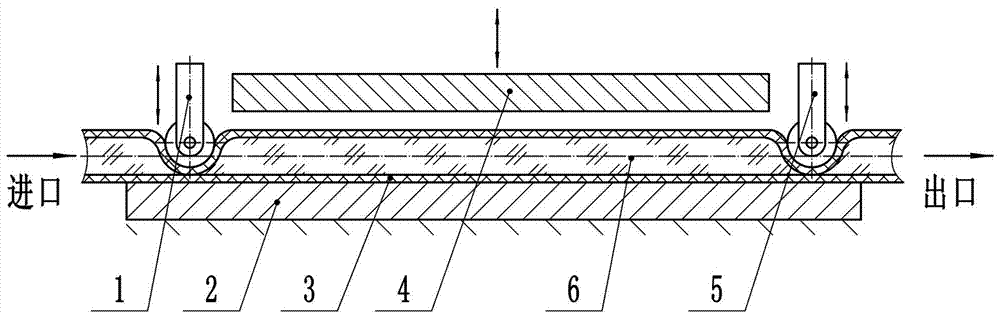

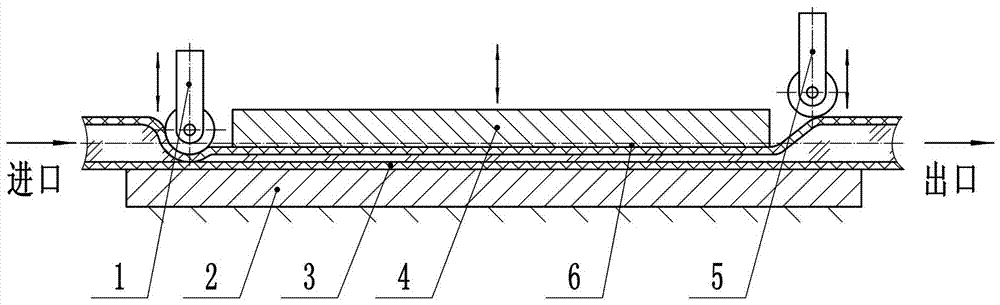

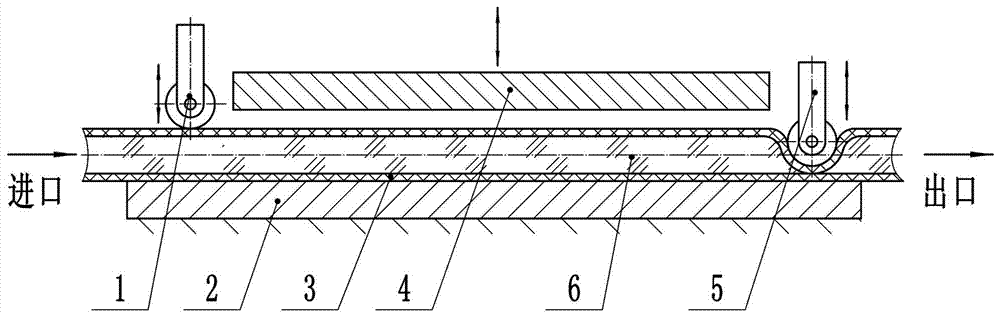

[0045] Embodiment 1: as Figure 1 ~ Figure 3 As shown, the present invention further provides a direct pressure fluid metering device, comprising an inlet pressure pipe mechanism 1, a fixed seat 2, an elastic hose 3, a flat pressure extrusion mechanism 4 and an outlet pressure pipe mechanism 5, wherein the fluid 6 is elastically Flow in the hose 3 , one end of the elastic hose 3 is an outlet for discharging the fluid 6 , and the other end of the elastic hose 3 is an inlet for inhaling the fluid 6 . The elastic hose 3 is flatly laid on the fixing seat 2 , the two ends of the elastic hose 3 are respectively provided with an inlet pressure pipe mechanism 1 and an outlet pressure pipe mechanism 5 , and the flat pressure extrusion mechanism 4 is arranged above the elastic hose 3 .

[0046] In a specific application example, the flat pressing mechanism 4 has its own drive, so that the flat pressing mechanism 4 moves up and down to squeeze and loosen the hose, so as to complete the a...

Embodiment 2

[0049] Embodiment 2: as Figure 4 As shown, the present invention further provides a direct pressure fluid metering device, comprising an inlet pressure pipe mechanism 1, a fixed seat 2, an elastic hose 3, an inlet control valve 7 and an outlet control valve 8, wherein the fluid 6 is in the elastic hose 3 One end of the elastic hose 3 is an outlet for discharging the fluid 6 , and the other end of the elastic hose 3 is an inlet for inhaling the fluid 6 . The elastic hose 3 is flatly laid on the fixing seat 2 , and the flat pressing extrusion mechanism 4 is arranged above the elastic hose 3 .

[0050] In a specific application example, the flat pressing mechanism 4 has its own drive, so that the flat pressing mechanism 4 moves up and down to squeeze and loosen the hose, so as to complete the actions of liquid inlet and outlet.

[0051] When working, first the inlet control valve 7 is turned off, so that the inlet end of the elastic hose 3 forms a closed state; then the outlet ...

Embodiment 3

[0052] Embodiment 3: as Figure 5 ~ Figure 7 As shown, the present invention further provides a direct pressure fluid metering device, comprising an inlet pressure pipe mechanism 1, a fixed seat 2, an elastic hose 3, an upper rotary extrusion mechanism 9 and an outlet pressure pipe mechanism 5, wherein the fluid 6 is elastically Flow in the hose 3 , one end of the elastic hose 3 is an outlet for discharging the fluid 6 , and the other end of the elastic hose 3 is an inlet for inhaling the fluid 6 . The elastic hose 3 is flatly laid on the fixed seat 2, and the two ends of the elastic hose 3 are respectively provided with an upper rotary extrusion mechanism 9 and an outlet pressure pipe mechanism 5, and the flat pressing extrusion mechanism 4 is arranged above the elastic hose 3.

[0053] In a specific application example, the upper rotary extruding mechanism 9 has its own drive, and can reciprocate and rotate around a fulcrum at one end during operation, so as to squeeze and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com