Material dissolving-mixing dynamic reaction hybrid system and method

A mixing system and dynamic technology, applied in the direction of mixing methods, fluid mixers, dissolution, etc., can solve the problems of many required equipment, inconvenient cleaning, slow dissolution speed, etc., achieve low manufacturing cost and maintenance cost, and save machinery Transmission and accessories, the effect of facilitating sterilization and disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

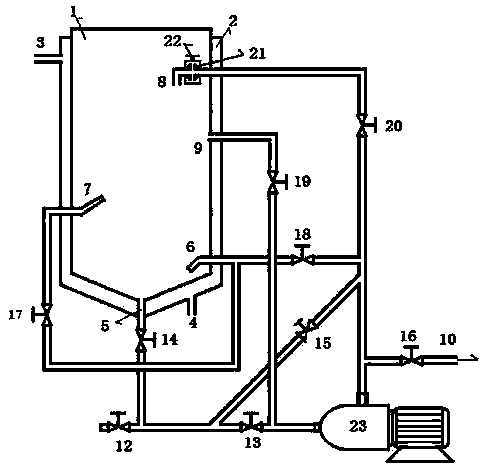

[0017] control figure 2 , a dynamic reaction mixing system for dissolving and dissolving materials, comprising: a columnar tank 1; a first vertical injection port 5, which is arranged at the center of the bottom of the columnar tank 1, and the injection direction coincides with the central axis of the columnar tank, from bottom to top; the first The horizontal injection port 6 is arranged on the columnar tank tank wall, and the injection direction is perpendicular to the injection direction of the first vertical injection port, and does not intersect with the central axis of the columnar tank body; the first horizontal injection port 6 is vertically separated from The distance from the bottom of the columnar tank is 0.1 times the height of the wall of the columnar tank; the distance from the wall of the columnar tank in the horizontal direction is 0.15 times the inner diameter of the columnar tank.

[0018] The second horizontal injection port 7 is arranged on the tank wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com