Oil flushing inspection device and method for pipe system

An inspection device and oil flushing technology, which is applied to measuring devices, material inspection products, instruments, etc., can solve the problems of easily damaged electro-hydraulic servo valves, increased equipment use costs, and equipment must be shut down for maintenance, etc., to achieve a fast and convenient detection method. , Putting in fast and convenient, improving the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

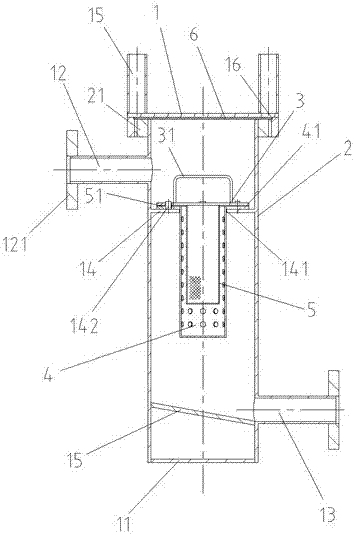

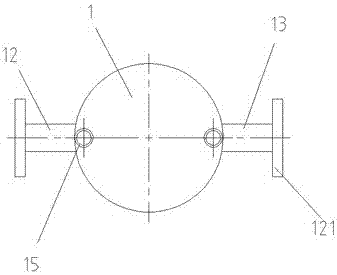

[0022] The present invention will be further described below in conjunction with the accompanying drawings and the embodiment of the piping system on the marine low-speed diesel engine.

[0023] Such as figure 1 and figure 2 As shown, the pipe system oil injection flushing inspection device of the present invention includes a top cover 1, a cylinder body 2, a movable platen 3, a coarse filter cartridge 4 and a fine filter bag 5. The cylinder body 1 of this embodiment adopts a diameter of Φ168mm and a wall thickness of 5mm It is made of steel pipe, the bottom of which is welded with a bottom plate 11, the left side of the upper end of the cylinder body 1 is vertically welded to the lubricating oil input pipe 12 with a diameter of Φ42 mm, and the right side of the lower end of the cylinder body 1 is vertically welded to the lubricating oil output pipe 13. The outer side of the pipe 12 and the lubricating oil output pipe 13 is welded with a flange 121 for easy connection with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com