Device for dosing bulk material

A dosing and machine technology, which is applied to a bulk material (Schüttgut) for dosing, especially in the field, can solve the problems of waste and consumption of cover plates, and achieve the effects of economical manufacturing, reasonable modeling and shortening of cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

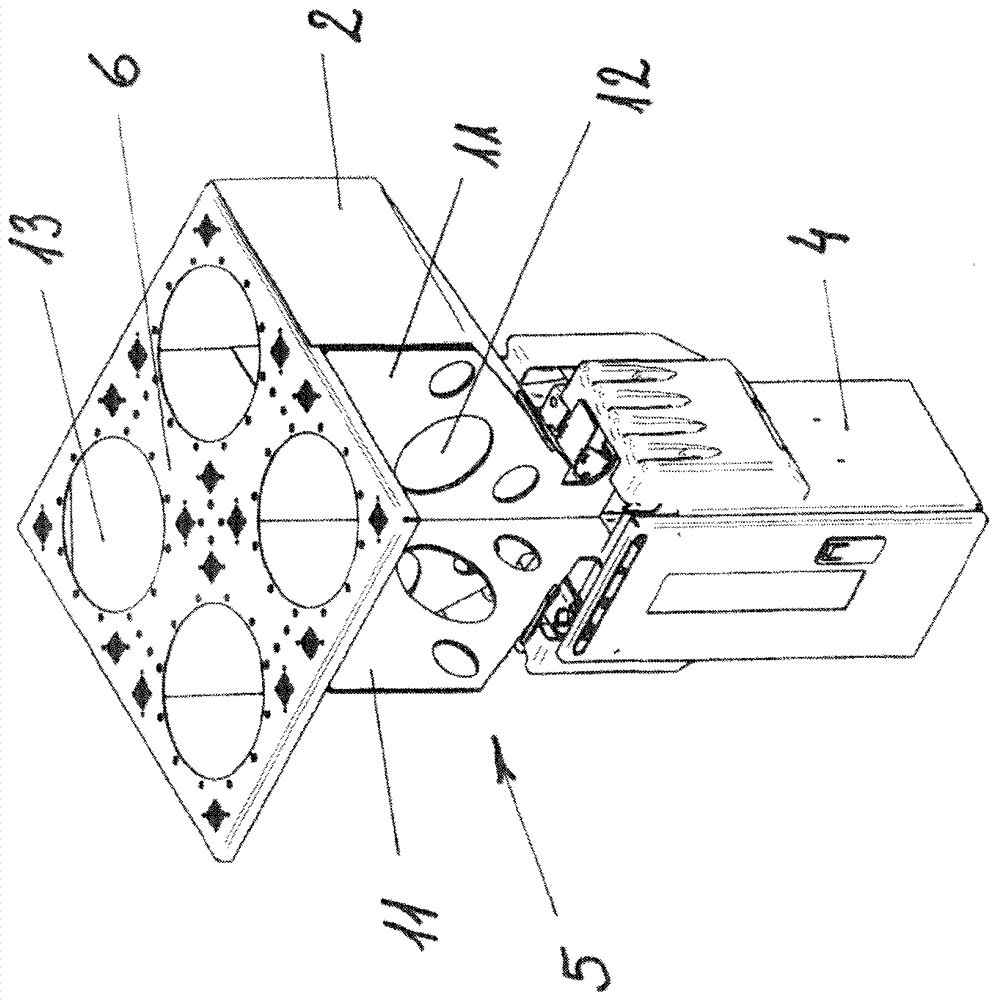

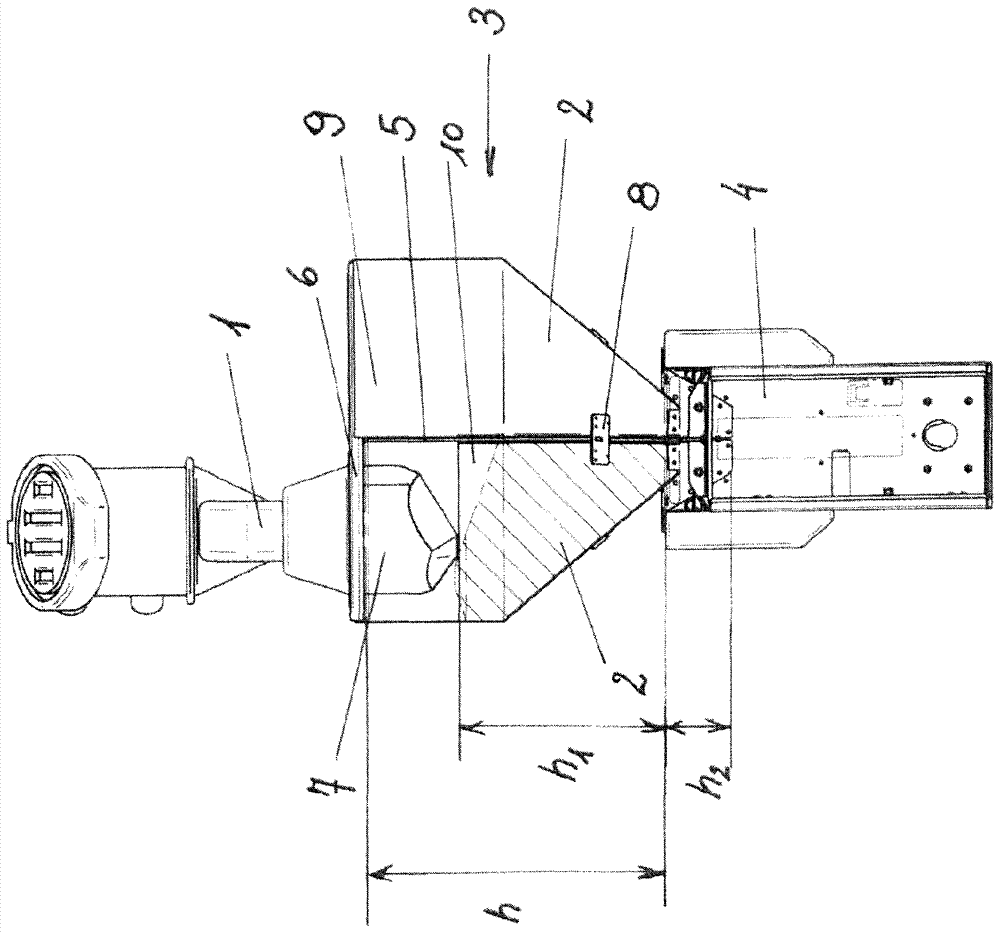

[0027] A device for dosing bulk materials, in particular plastic granules, for machines processing plastic granules, in particular for injection molding machines, is designed in a modular manner. according to figure 1 The mechanism comprises a bulk material inlet 1 , for example a material separator, a material hopper 3 arranged below the bulk material inlet 1 and consisting of a plurality of, preferably four, individually removable material hopper containers 2 . The material funnel 3 terminates in the metering basic device 4 . A weighing container with a scale is optionally arranged in the metering basic device 4 . The individual material funnel containers 2 are arranged on a carrier cross 5 , wherein the carrier cross 5 is formed by carrier cross plates 11 arranged vertically at right angles to one another and mounted on the dosing base Instrument 4.

[0028] The carrier cross 5 has a height h which corresponds at least to the height h of the material funnel container 2 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com