Production method of vulcanized rubber composition, vulcanized rubber composition, and studless tire using the same

A vulcanized rubber and composition technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of increased hardness difference, decreased rubber strength and wear resistance, and achieves excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

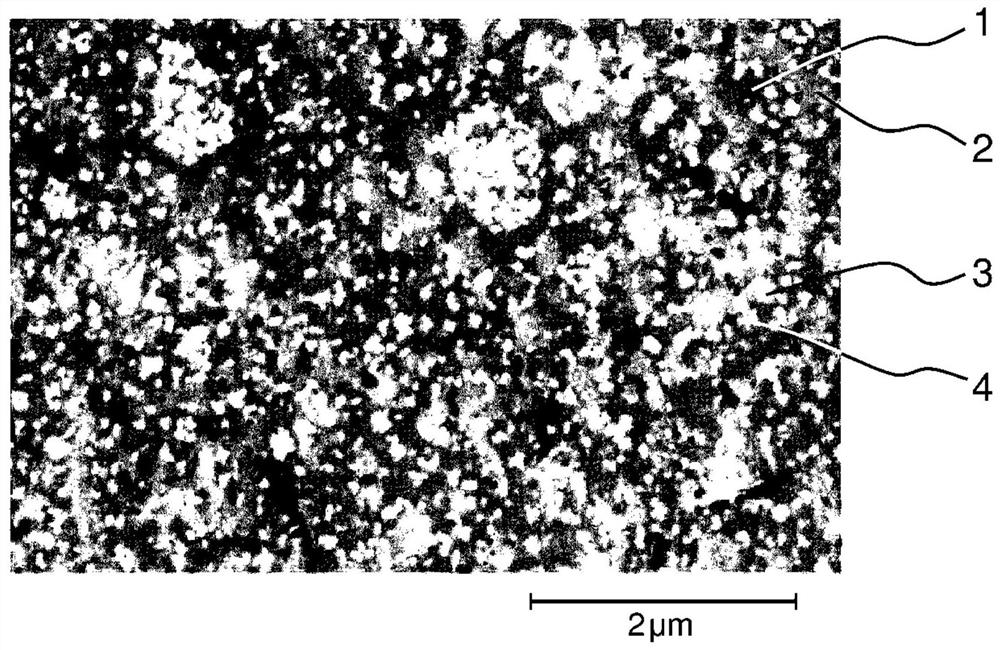

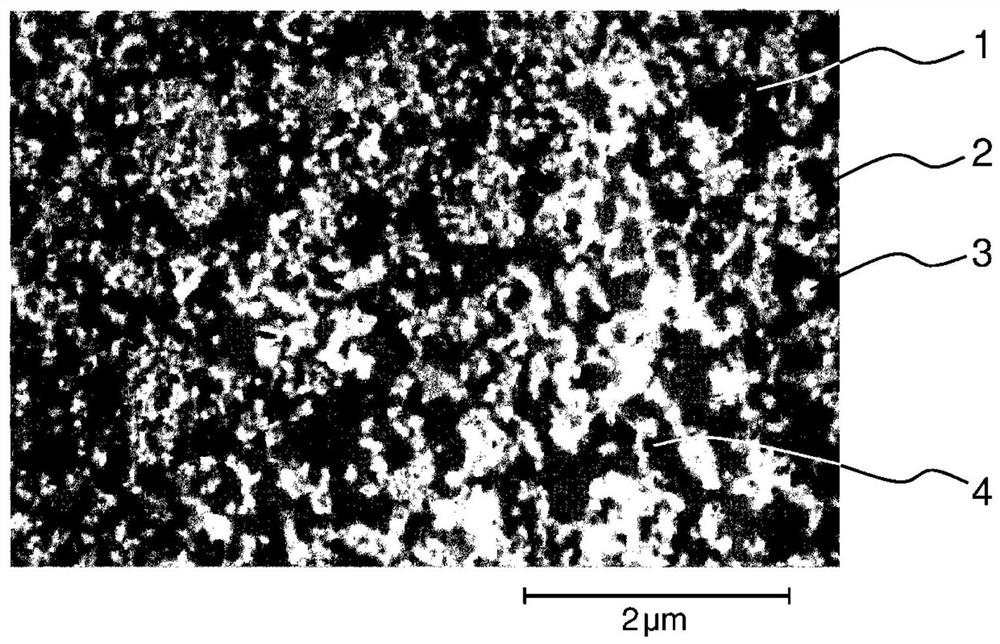

[0062] As an embodiment of the present invention, the preparation method of the vulcanized rubber composition comprises: (a) the step of preparing a masterbatch (BR masterbatch) comprising butadiene rubber (BR) and silica; (b) preparing a step of preparing A step of masterbatch (IR masterbatch) of diene rubber (IR) and silica; (c) kneading the BR masterbatch obtained in step (a) with the IR masterbatch obtained in step (b) step; and (d) a step of vulcanizing the kneaded product obtained in step (c), and the obtained vulcanized rubber composition has predetermined properties. As mentioned above, by kneading the masterbatch prepared by kneading each rubber component separately with silica, silica which is easy to localize in isoprene rubber such as natural rubber can also be kneaded in butadiene rubber localization, it is possible to easily prepare a vulcanized rubber composition that satisfies the specified abundance ratio α of silica in the BR phase and satisfies the specified...

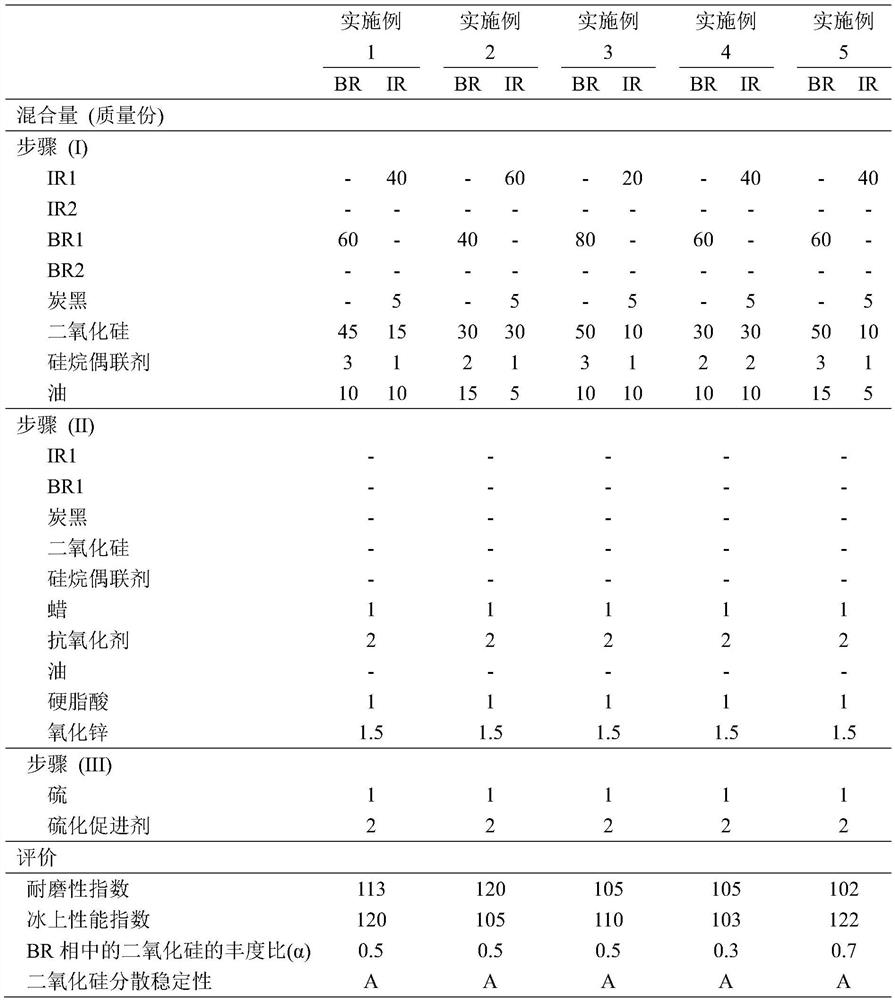

Embodiment 1~10 and comparative example 1~5

[0144] According to the formula shown in step (I) of Table 1 or 2, using a 1.7L Banbury mixer, the rubber component, silicon dioxide and other The materials were kneaded for 3 minutes to obtain a kneaded product (BR master batch) containing butadiene rubber and silica, and a kneaded product (IR master batch) containing isoprene rubber and silica, respectively. Next, the obtained kneaded product and other materials according to the formula shown in the step (II) of Table 1 or 2 are mixed for 5 minutes at a mixing temperature of 150° C. when discharged from the internal mixer, so that to obtain a kneaded product. According to the formulation shown in step (III) of Table 1 or 2, sulfur and a vulcanization accelerator were added to the obtained kneaded product, followed by kneading for 5 minutes at a temperature of 150° C. using an open roll to obtain Unvulcanized rubber composition. In the case where the mixing amount is not described in step (I) of Table 1 or 2, only step (II)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com