Rotor spinning machine comprising a plurality of working positions and a suction device

A textile machine and airflow technology, which is applied in the field of airflow textile machines with multiple stations and air extraction devices, can solve the problems of difficult machine maintenance and cleaning, difficult access, etc., and achieve a low-cost operation mode, save energy, and reduce pressure. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

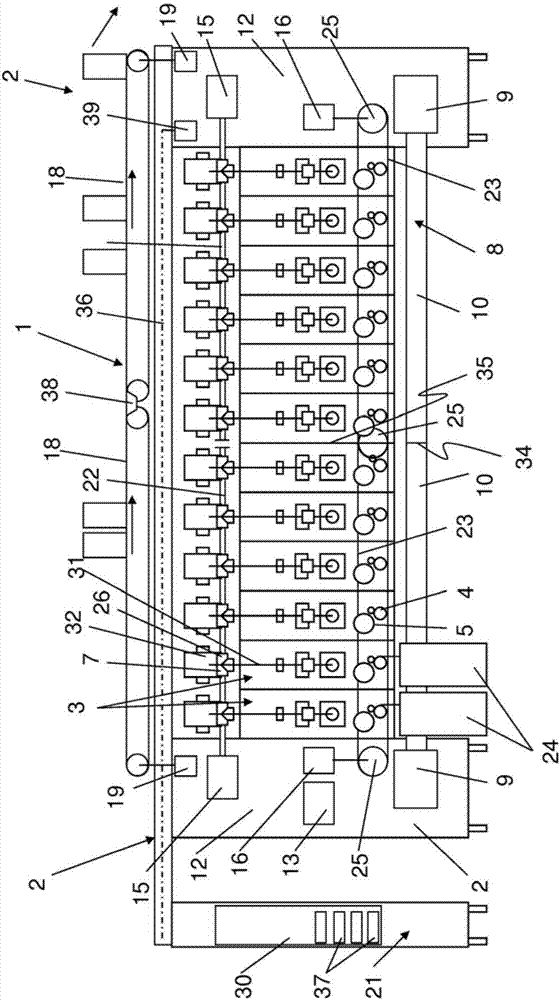

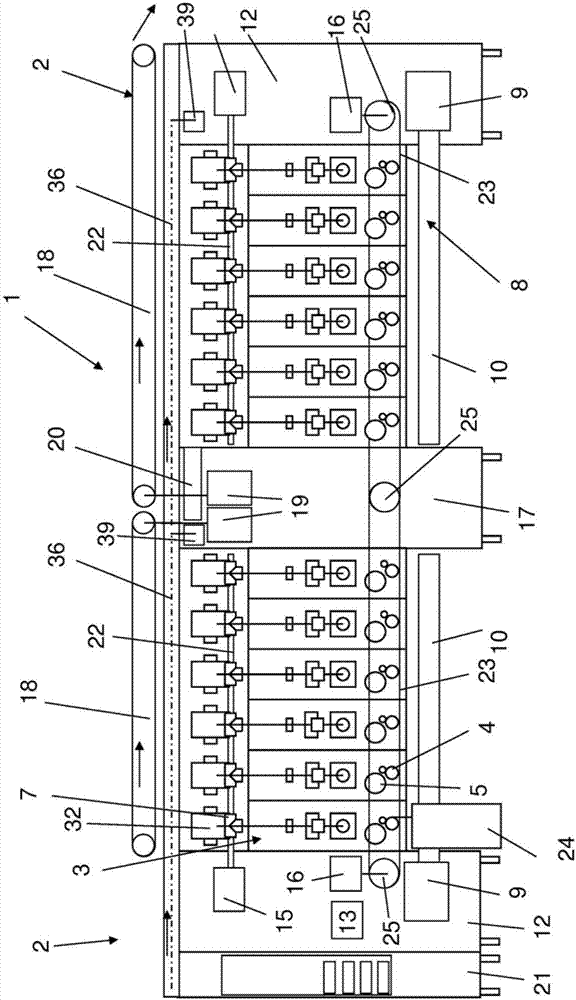

[0034] figure 1 A schematic illustration of an air spinning machine 1 is shown, which is particularly suitable for arranging a plurality of work stations 3 side by side in the longitudinal direction of the air spinning machine 1 . The air spinning machine 1 has a plurality of work stations 3 arranged next to each other between two end parts 2 , each of which has a plurality of working elements 4 , 5 , 6 , 7 in a known manner for producing and winding yarn 31 . Each station 3 has a feed device 4 by means of which the fibrous material is transported from a storage container 24 to a debonding device 5 . The debonding device supplies the fiber material debonded into individual fibers to the spinning rotor 6 , where the fiber material is spun into a yarn 31 and finally wound on a bobbin 32 by means of a winding device 7 .

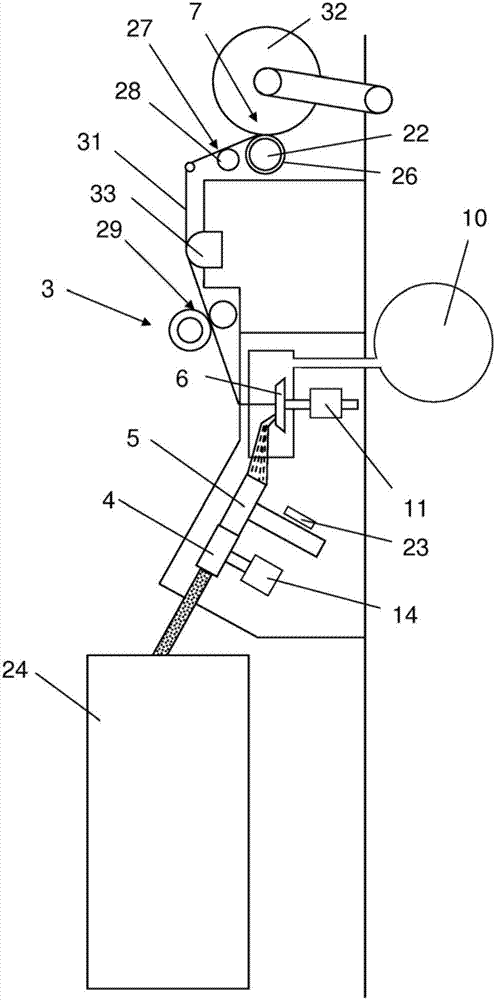

[0035] figure 2 The working elements 4 , 5 , 6 , 7 are precisely shown in the schematic sectional view of the workstation 3 . according to figure 2 , can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com