A shoe material cutting device

A cutting and shoe material technology, applied in the direction of footwear, heel pads, shoe-making machinery, etc., can solve the problems of unable to meet mass production, unable to meet small batch, personalized production, etc., to prevent wrinkles, improve The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific embodiments.

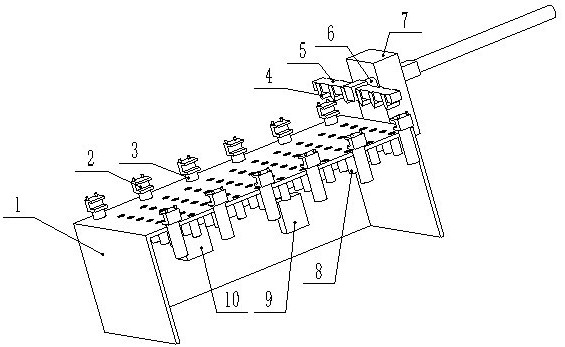

[0015] like figure 1 The shown shoe material cutting device, the multi-blade knife group can adjust the number and spacing of detachable cutting knives as needed to meet different production needs; the air cushion assembly is used to automatically adjust the level of the shoe material to be cut. to prevent wrinkles and other phenomena; the shoe material fixing component has a sequential fixing function, which effectively improves the automation level of cutting.

[0016] In order to achieve the above-mentioned purpose, the technical scheme adopted in the present invention is: a shoe material cutting device, comprising a cutting table 1, an air cushion assembly, a multi-blade knife group and a shoe material fixing assembly, and the shoe material fixing assembly will firstly cut the to-be-cut material during use. The shoe material is cut by one end of the cutting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com